PVC Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

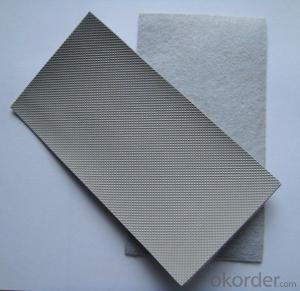

Introduction for PVC Waterproofing Membrane

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

1.Technical data of PVC Membrane

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

2.Characteristic of PVC Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

3.Applicable scope of PVC Membrane

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

4. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on roofs or only on vertical surfaces?

- Both roofs and vertical surfaces can benefit from the use of a waterproofing membrane. It is a common practice to utilize this membrane to safeguard roofs against water-related harm. Specifically designed as a barrier against water infiltration, roofing membranes guarantee a dry and leak-free structure. These membranes are applied to the roof's surface, forming a protective layer that prevents water from seeping through. In a similar manner, waterproofing membranes can also be employed on vertical surfaces, such as walls, to prevent water ingress and safeguard the underlying structure. The primary objective of a waterproofing membrane is to establish a watertight seal, regardless of whether it is used on a horizontal or vertical surface. Therefore, whether it is a roof or a vertical wall, a waterproofing membrane is an effective solution for shielding against water damage.

- Q: SBs waterproof cold sticky how to do?

- 5, protective layer construction. In order to shield or reflect the sun's radiation, to extend the life of the waterproof layer of the membrane, in the waterproof layer is completed and checked after passing, should be coated on the surface of the waterproof layer of adhesive, side of the expansion of the expansion of silica powder protective layer, or uniform Brush the silver or green paint as a protective layer.

- Q: Can a waterproofing membrane be painted or covered with a protective layer?

- Yes, a waterproofing membrane can be painted or covered with a protective layer. This can help enhance its durability and resistance to external elements. However, it is important to ensure that the paint or protective layer used is compatible with the waterproofing membrane to maintain its effectiveness and prevent any potential damage.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Yes, a waterproofing membrane can be used on metal block surfaces. Waterproofing membranes are designed to create a barrier against water and moisture, and they can be applied to a variety of surfaces, including metal. The membrane will adhere to the metal surface, creating a waterproof layer that helps prevent water infiltration and protect the metal from rusting or corrosion. However, it is important to ensure that the metal surface is clean, dry, and properly prepared before applying the waterproofing membrane to ensure proper adhesion and effectiveness. Additionally, it is recommended to consult with a professional or refer to the manufacturer's instructions for specific guidance on using a waterproofing membrane on metal block surfaces.

- Q: Can a waterproofing membrane be used for swimming pools and water features?

- Yes, a waterproofing membrane can be used for swimming pools and water features.

- Q: Can a waterproofing membrane be applied to tiled surfaces?

- Certainly! A tiled surface can indeed receive the application of a waterproofing membrane. In reality, it is customary to utilize a waterproofing membrane beneath tiled surfaces, particularly in regions susceptible to moisture like bathrooms, showers, and kitchen backsplashes. The waterproofing membrane serves as a shield, thwarting water infiltration into the foundation, thereby safeguarding both the tiles and the underlying structure against water-related harm. Before applying the waterproofing membrane for best outcomes, it is crucial to ensure that the tiled surface is adequately prepared and devoid of any fissures or impairments.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Yes, a waterproofing membrane can be used in basements and foundations. Waterproofing membranes are specifically designed to prevent the penetration of water and moisture, making them an effective solution for protecting basements and foundations from water damage.

- Q: Are waterproofing membranes resistant to acid exposure?

- Waterproofing membranes can vary in their resistance to acid exposure depending on the specific type of membrane being used. Some waterproofing membranes are designed to be resistant to acid exposure, while others may not be. It is crucial to carefully select the appropriate waterproofing membrane for the specific application and environment where acid exposure may be a concern. It is also advisable to consult with manufacturers or industry experts to determine the best waterproofing membrane solution for acid-prone areas.

- Q: How does a waterproofing membrane handle extreme temperature fluctuations?

- To withstand extreme temperature fluctuations, a waterproofing membrane is crafted with resistance to temperature changes. Typically, it is composed of materials that possess a high tolerance for both hot and cold temperatures. The selection of these materials is based on their capability to expand and contract without compromising their integrity or effectiveness. In hot weather, the waterproofing membrane undergoes slight expansion to accommodate the rise in temperature. This expansion serves to prevent the formation of cracks or gaps that may allow water to infiltrate the membrane. Similarly, in cold weather, the membrane contracts to prevent damage caused by freezing temperatures. The ability of a waterproofing membrane to handle extreme temperature fluctuations is also achieved through its installation process. Usually, the membrane is applied in multiple layers, creating a seamless and flexible barrier. This layered application enables the membrane to endure the strains caused by temperature changes while upholding its protective properties. Furthermore, certain waterproofing membranes are equipped with special additives or reinforcements that enhance their capacity to handle extreme temperature fluctuations. These additives provide additional strength and flexibility, ensuring the membrane remains intact and functional even in the face of severe temperature changes. Ultimately, a properly installed and maintained waterproofing membrane is intended to handle extreme temperature fluctuations by expanding and contracting, maintaining its integrity, and delivering a consistent barrier against water intrusion.

- Q: Are waterproofing membranes resistant to alkalis?

- Yes, waterproofing membranes are generally resistant to alkalis. Alkalis are substances with a high pH level, such as sodium hydroxide or potassium hydroxide, and can be found in various construction materials, including concrete. Waterproofing membranes are specifically designed to provide a protective barrier against water and other potentially damaging substances. They are typically made from materials such as modified bitumen, PVC, or EPDM, which have excellent resistance to alkalis. This resistance ensures that the waterproofing membrane remains intact and effective, even when exposed to alkaline substances. It is important to choose a waterproofing membrane that is specifically designed for alkali resistance when working with materials or environments that contain high levels of alkalis.

Send your message to us

PVC Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords