PVC waterproof membrane About 1.2mm, 1.5mm, 2.0mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

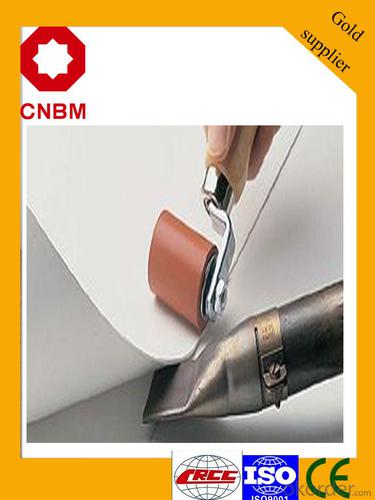

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can waterproofing membranes be used on foundation walls?

- Yes, waterproofing membranes can be used on foundation walls. Waterproofing membranes are specifically designed to prevent water infiltration and are commonly applied to foundation walls to protect them from moisture and water damage. These membranes are typically made of materials such as rubberized asphalt, thermoplastic, or PVC, which are durable and resistant to water penetration. They are installed on the exterior side of the foundation walls and provide an effective barrier against water, preventing it from seeping into the basement or crawl space. Waterproofing membranes are an essential component of building construction, as they help maintain the structural integrity of the foundation and prevent issues such as water damage, mold growth, and foundation settlement.

- Q: Is a waterproofing membrane resistant to chemicals?

- Yes, a waterproofing membrane is typically resistant to chemicals. Waterproofing membranes are designed to provide a protective barrier against water and other liquids, including chemicals. These membranes are made of materials that are chemically resistant, such as PVC (polyvinyl chloride), TPO (thermoplastic olefin), or EPDM (ethylene propylene diene monomer). These materials have excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. Additionally, waterproofing membranes undergo rigorous testing to ensure their chemical resistance and durability. However, it is important to note that the specific chemical resistance may vary depending on the type and quality of the membrane. It is always recommended to consult the manufacturer's specifications and guidelines to ensure the membrane's compatibility with specific chemicals.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Indeed, rooftop terraces can utilize waterproofing membranes. In fact, they are frequently employed to safeguard the terrace's structural integrity and prevent water damage to the underlying structure. Rooftop terraces are exposed to diverse weather conditions, encompassing rain, snow, and UV rays, which can result in leaks and deterioration. Waterproofing membranes function as a barrier, impeding water from permeating the surface and causing harm. These membranes are specifically engineered for outdoor usage and can endure the harsh conditions commonly encountered on rooftops. They are obtainable in various materials, such as modified bitumen, EPDM (ethylene propylene diene terpolymer), and PVC (polyvinyl chloride), allowing for flexibility in selecting the most suitable option for a specific terrace. Moreover, waterproofing membranes can be installed beneath a variety of terrace finishes, including pavers, tiles, and decking, offering a versatile solution for diverse design preferences. Overall, it is highly advisable to employ waterproofing membranes for rooftop terraces to ensure their longevity, durability, and resistance to water-related problems.

- Q: How does a waterproofing membrane handle movement or settling of a building?

- A building's movement or settling can be accommodated by a waterproofing membrane in several ways. Firstly, the membrane is typically installed in a manner that allows it to stretch or flex as the building moves. This elasticity ensures that the membrane remains intact and continues to provide a watertight seal, even if the structure shifts or settles. In addition, waterproofing membranes often include reinforcement materials, such as fabrics or fibers, which enhance their ability to withstand movement. These reinforcements help distribute the stress or strain caused by building movement across a larger area, reducing the risk of tears or failures in the membrane. Moreover, certain waterproofing membranes are designed with built-in features that can handle significant movement. For instance, some membranes possess special "crack-bridging" properties, enabling them to span small cracks that may develop in the building's substrate due to settling. This ensures that the membrane remains effective, even if the structure sustains minor damage. In cases where a building is expected to experience significant movement or settling, specialized waterproofing systems, such as joint sealants or expansion joints, may be used in conjunction with the membrane. These systems are specifically designed to handle large or dynamic movements, providing additional protection against water infiltration. Overall, careful design and installation of a waterproofing membrane enable it to effectively handle a building's movement or settling. Its elasticity, reinforcement materials, and additional features ensure that it maintains a watertight seal, even when faced with structural shifts or settlement.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Precast metal surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically designed to create a protective layer that stops water from penetrating the surface. They can be used on various types of surfaces, including precast metal. Waterproofing membranes are typically made from materials like bitumen, liquid coatings, or synthetic rubber. These materials form a barrier that prevents water and moisture from causing damage. When a waterproofing membrane is applied to precast metal surfaces, it helps to prevent corrosion, protects against water damage, and improves the overall durability and lifespan of the metal structure. However, it is crucial to select a waterproofing membrane that is compatible with the specific type of precast metal surface. Additionally, proper surface preparation and application techniques must be followed to ensure optimal performance.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Indeed, it is possible to utilize a waterproofing membrane on both the inner and outer walls. Said membranes are specifically devised to thwart the infiltration of water or moisture into the walls, irrespective of their positioning within a structure. Typically, these membranes are crafted from materials like rubber, modified bitumen, or liquid-applied coatings, which serve as a potent barricade against water seepage. Through the application of a waterproofing membrane on both the interior and exterior walls, one can guarantee the prolonged defense of the building against water-related harm, such as mold proliferation and other moisture-induced predicaments.

- Q: Can a waterproofing membrane be used in residential construction?

- Residential construction can indeed utilize a waterproofing membrane. These membranes find common usage in different parts of a residential property, such as roofs, basements, bathrooms, and foundations. Their purpose is to prevent water from penetrating and causing damage due to moisture. By opting for a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks. This is crucial because such leaks can result in mold growth, structural deterioration, and other costly problems. The market offers a variety of waterproofing membranes, such as sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can assist in determining the most suitable waterproofing membrane for a particular residential construction project.

- Q: Can a waterproofing membrane be used in foundations?

- Yes, a waterproofing membrane can be used in foundations. In fact, it is often recommended to install a waterproofing membrane in foundations to prevent water infiltration and potential damage to the structure. The membrane is typically applied to the exterior walls of the foundation and acts as a barrier against water penetration. It helps to keep the foundation dry and protects it from hydrostatic pressure, which can cause cracks and leaks. Additionally, a waterproofing membrane can also prevent moisture buildup, mold growth, and other issues related to water damage. Overall, using a waterproofing membrane in foundations is an effective and reliable method to ensure the long-term durability and stability of a building.

- Q: Can a waterproofing membrane be used on stainless steel surfaces?

- Yes, a waterproofing membrane can be used on stainless steel surfaces. Stainless steel is a durable and non-corrosive material that is commonly used in various industries. However, it is not completely immune to water damage or corrosion, especially in harsh environments. Applying a waterproofing membrane on stainless steel surfaces can provide an additional layer of protection against moisture, preventing potential water damage, rusting, and corrosion. It is important to ensure that the waterproofing membrane is compatible with stainless steel and applied correctly to ensure proper adhesion and long-lasting protection.

Send your message to us

PVC waterproof membrane About 1.2mm, 1.5mm, 2.0mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords