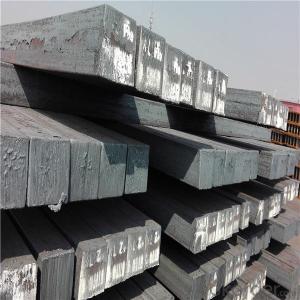

Prime square steel billet best price from China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14721 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets

are also known for their malleability and ductility, especially when exposed to varying temperatures during

shaping and molding.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

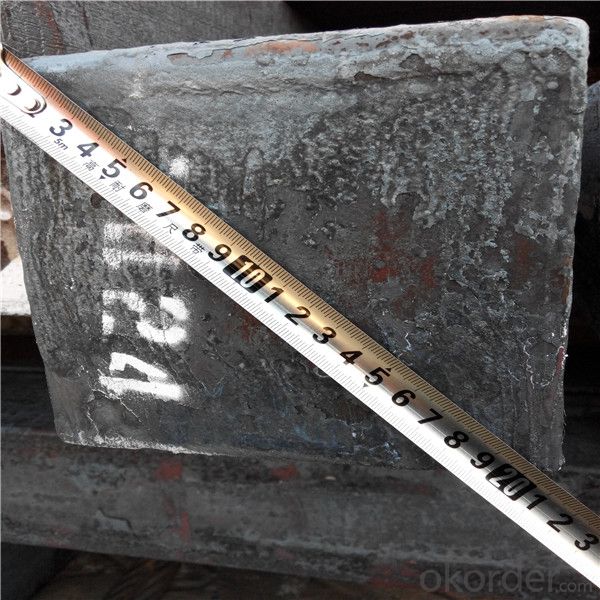

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How do steel billets contribute to the overall vibration resistance of a product?

- Steel billets are an essential component in enhancing the overall vibration resistance of a product. The high-strength properties of steel make it an ideal material for reducing vibrations and improving product stability. Steel billets are typically used as a raw material in the manufacturing process, where they are further processed into various shapes and forms. The dense and uniform structure of steel billets allows them to absorb and dissipate vibration energy effectively. When integrated into a product, steel billets provide additional mass, which helps dampen vibrations by absorbing and distributing the energy throughout the structure. This mass acts as a stabilizing force, preventing excessive movement and reducing the amplitude of vibrations. Moreover, steel billets possess excellent mechanical properties, such as high tensile strength and stiffness, which contribute to the overall vibration resistance of a product. These properties enable steel billets to withstand dynamic forces and resist deformation under vibration, ensuring the structural integrity of the product. Additionally, steel billets can be engineered to have specific geometries and cross-sectional shapes that further enhance their vibration resistance. For example, the use of round or square billets with smooth surfaces minimizes stress concentration points and reduces the risk of fatigue failure. By optimizing the design and dimensions of steel billets, manufacturers can tailor the vibration resistance of a product to meet specific requirements. In summary, steel billets play a crucial role in improving the overall vibration resistance of a product. Their high mass, dense structure, and superior mechanical properties enable them to absorb and dissipate vibration energy, stabilize the product, and enhance its structural integrity. By utilizing steel billets in the manufacturing process, manufacturers can ensure that their products are more resistant to vibrations, leading to improved performance and longevity.

- Q: How are steel billets different from steel ingots?

- Steel billets and steel ingots are both intermediate products in the steel manufacturing process, but they differ in terms of their shape and size. Steel billets are smaller and have a square or rectangular cross-section, typically measuring less than 36 square inches. In contrast, steel ingots are larger and have a more irregular shape, often weighing several tons. Additionally, steel billets are typically produced using continuous casting methods, while steel ingots are typically made through traditional ingot casting processes.

- Q: If the casting speed is not steady, what will happen to the billet?

- Secondly, the speed of cutting is unstable, and the cut rate will be reduced.

- Q: How do steel billets contribute to the manufacturing of textile machinery?

- Steel billets are a crucial component in the manufacturing of textile machinery due to their mechanical properties and versatility. Steel billets are essentially semi-finished steel products, typically in a rectangular or square shape, that are used as raw material in various industries, including textile machinery manufacturing. One of the primary ways steel billets contribute to the manufacturing of textile machinery is through the production of structural components. Textile machinery requires sturdy and durable frames, supports, and other structural elements to ensure stability and efficient functioning. Steel billets, with their high strength and rigidity, serve as an ideal material for these components. They can be easily shaped, machined, or welded to create intricate and complex structures that can withstand the heavy loads and vibrations associated with textile machinery. Additionally, steel billets are often used to produce shafts, gears, and other moving parts in textile machinery. These components need to have excellent wear resistance, high tensile strength, and good machinability to ensure smooth operation and a long service life. Steel billets, through various processes such as forging, rolling, or machining, can be transformed into these critical parts, providing the necessary mechanical properties and precision required for textile machinery. Moreover, steel billets are utilized in the manufacturing of tooling and molds used in textile machinery production. These tools and molds are essential for shaping and forming various components or parts of the machinery. Steel billets, when subjected to heat treatment and precise machining processes, can be transformed into high-quality tooling and molds that offer exceptional dimensional accuracy and durability. This contributes to the overall efficiency and quality of textile machinery production. In summary, steel billets play a pivotal role in the manufacturing of textile machinery by providing the raw material for structural components, moving parts, and tooling. Their mechanical properties, versatility, and ease of fabrication make them an indispensable material for the industry. Steel billets ensure the durability, precision, and functionality of textile machinery, ultimately contributing to the overall performance and reliability of the equipment.

- Q: What are the main challenges in the quality control of steel billets?

- The main challenges in the quality control of steel billets include several factors that can affect the final product's quality and performance. Here are some of the key challenges: 1. Chemical Composition: Ensuring the accurate chemical composition of steel billets is crucial as it determines the material's strength, durability, and other mechanical properties. Maintaining consistent chemical composition is challenging due to variations in raw materials, melting processes, and the presence of impurities. 2. Homogeneity: Achieving uniformity in the microstructure and composition throughout the steel billet is essential. Inadequate mixing or non-uniform cooling can lead to inconsistencies, resulting in weak spots and uneven mechanical properties. 3. Defect Detection: Identifying and eliminating defects in steel billets is essential to prevent failures during subsequent processing and usage. Common defects include cracks, inclusions, segregation, porosity, and surface irregularities. Detecting these defects accurately and in a timely manner can be challenging due to the size, complexity, and location of certain defects. 4. Dimensional Accuracy: Consistency in the dimensions and shape of steel billets is crucial for their further processing and use in various applications. Maintaining precise dimensions requires controlling variables such as casting speed, cooling rates, and mold design. 5. Surface Quality: The surface condition of steel billets is critical for subsequent operations like rolling, forging, or machining. Ensuring a smooth, clean, and defect-free surface is challenging due to factors such as scale formation, oxidation, decarburization, and surface contamination during handling and storage. 6. Heat Treatment: Proper heat treatment is often necessary to achieve the desired mechanical properties in steel billets. However, controlling the heating and cooling rates, as well as the soaking times, can be challenging due to variations in equipment, temperature monitoring, and quenching techniques. 7. Traceability: Maintaining traceability and documentation throughout the production process is crucial for quality control. Tracking the origin of raw materials, process parameters, testing records, and certifications can be challenging, especially in complex supply chains. Addressing these challenges in the quality control of steel billets requires a combination of advanced testing techniques, robust process controls, skilled personnel, and continuous improvement initiatives.

- Q: What is the role of steel billets in the automotive industry?

- Steel billets play a crucial role in the automotive industry as they are used as the primary raw material for manufacturing various components and parts of vehicles. These billets are transformed into different shapes and sizes through processes like forging, rolling, and machining to create engine parts, chassis components, axles, and other structural elements. With their strength, durability, and versatility, steel billets enable the automotive industry to produce high-quality and reliable vehicles, ensuring safety and performance for drivers and passengers.

- Q: What is the role of steel billets in the manufacturing of cutting tools?

- Steel billets play a crucial role in the manufacturing of cutting tools as they are the starting material for producing high-quality tool steels. These billets are heated, forged, and machined to form the desired shape and size of cutting tools such as drills, saw blades, and milling cutters. The strength and durability of the cutting tools largely depend on the quality and composition of the steel billets used.

- Q: How do steel billets contribute to the overall weight reduction of a structure?

- Steel billets contribute to the overall weight reduction of a structure by being a lightweight and high-strength material. They allow for the design of thinner and more efficient structural elements, reducing the amount of steel required, and consequently the weight of the structure.

- Q: What are the main factors affecting the surface finish of steel billets?

- The main factors affecting the surface finish of steel billets include the quality and cleanliness of the raw materials used, the temperature and pressure during the production process, the type and condition of the equipment used for processing, and the skill and expertise of the personnel involved in handling and finishing the billets. Additionally, factors such as the presence of impurities, chemicals, or contaminants, as well as the use of lubricants or surface treatments, can also impact the surface finish of steel billets.

- Q: What does "billet" mean?

- Steelmaking and continuous casting of steel products are mainly used for steel rolling, such as round bar, wire rod, sheet metal and so on

Send your message to us

Prime square steel billet best price from China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14721 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords