Prime quality prepainted galvanized steel 695mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

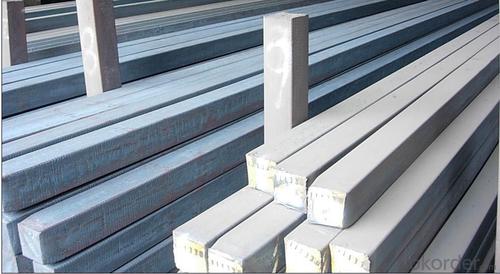

- Q: What are the common shapes of steel billets?

- Steel billets can come in a variety of shapes, depending on their intended use and manufacturing process. Some of the common shapes of steel billets include square, rectangular, round, and hexagonal. Square billets are often used for applications requiring stability and strength, such as construction materials and machinery parts. Rectangular billets, with their elongated shape, are commonly used for structural components in construction and engineering projects. Round billets are often used for manufacturing pipes, tubes, and other cylindrical objects. Hexagonal billets, with their six-sided shape, are frequently used in the production of hex nuts, bolts, and other fasteners. These different shapes provide versatility in meeting various industry requirements and applications.

- Q: Can steel billets be used in the production of appliances?

- Appliances can indeed utilize steel billets for their production. These semi-finished products are typically employed for subsequent processing into diverse forms and dimensions. In the context of appliances, steel billets can serve as the primary material for fabricating elements like frames, panels, and other structural components. Steel possesses remarkable versatility and durability, providing robustness, stability, and corrosion resistance, thereby rendering it appropriate for appliances requiring sturdy construction. Moreover, steel can be effortlessly molded and shaped to fulfill the distinct design requisites of various appliances, making it the preferred choice in the manufacturing procedure.

- Q: What are the different types of steel billet extrusion processes?

- The manufacturing industry utilizes various steel billet extrusion processes, each with its own distinct characteristics. These processes employ high pressure to shape solid steel billets into desired profiles or shapes. 1. The most frequently employed method is direct extrusion. This process involves placing the billet within a container, commonly referred to as a "container" or "container die." The container possesses a small opening, known as a "die," through which the billet is propelled using a ram or piston. The billet is then forced through the die, resulting in the formation of the desired shape. 2. Another technique, indirect extrusion, involves a stationary container die. The billet is pushed through the die using a punch or ram. The billet is positioned inside a hollow chamber called a "container" or "container die," featuring a smaller opening at one end. Pressure is applied to the billet using the punch, compelling it to flow through the die and adopt the desired profile. 3. Impact extrusion shares similarities with direct extrusion but incorporates a specially designed punch. This punch strikes the billet with a significant impact force, causing it to flow and take on the shape of the die. Impact extrusion is frequently utilized to produce small, intricate shapes with thin walls. 4. Hydrostatic extrusion employs a sealed chamber filled with a pressurized fluid, typically oil or water, in which the billet is placed. The fluid pressure is utilized to force the billet to flow through the die and acquire the desired shape. Hydrostatic extrusion is commonly employed for the production of complex shapes with high precision. 5. Cold extrusion is performed at room temperature without the need for heating the steel billet. This method is often used to produce small, intricate parts with high dimensional accuracy. It offers a cost-effective approach, enabling the production of parts with excellent surface finish. The selection of a specific steel billet extrusion process depends on various factors, including the desired shape, size, material properties, and production requirements. Each process has its own advantages and limitations.

- Q: What is the typical weight of a steel billet?

- The weight of a steel billet can differ based on its size and purpose, resulting in a range of common weights between 1,000 and 5,000 pounds (450 to 2,270 kilograms). This weight range grants flexibility in manufacturing processes and enables diverse applications across industries like construction, automotive, and manufacturing. It is crucial to acknowledge that distinct weight prerequisites might vary according to the steel billet's intended use and specifications.

- Q: What are the different types of tests conducted on steel billets?

- Steel billets undergo various tests to assess their quality and suitability for different applications. These tests play a crucial role in determining the mechanical properties, chemical composition, and overall integrity of the billets. 1. Analyzing Chemical Composition: The chemical composition of the steel billets is examined to ensure compliance with specified standards and requirements. This analysis measures the levels of carbon, manganese, silicon, sulfur, and phosphorus, among other elements. 2. Tensile Strength Evaluation: The tensile test assesses the ability of the steel billets to withstand pulling forces without breaking. It measures parameters such as tensile strength, yield strength, and elongation. 3. Determining Hardness: The hardness test evaluates the steel billets' resistance to wear, deformation, and penetration. It involves different hardness tests such as Brinell, Rockwell, and Vickers. 4. Assessing Impact Resistance: The impact test measures the toughness and capacity of the steel billets to absorb energy under sudden loading or impact conditions. It helps determine their resistance to fracture and cracking. 5. Ultrasonic Inspection: This non-destructive test employs high-frequency sound waves to detect internal flaws or defects in the steel billets. It is a valuable method for identifying cracks, voids, and inclusions that may compromise the billets' structural integrity. 6. Verifying Dimensions: The dimensional inspection ensures that the steel billets meet the specified dimensional requirements, including length, width, and thickness. This verification confirms their suitability for intended applications and subsequent manufacturing processes. 7. Macroscopic Examination: This visual inspection involves magnified examination of the steel billets' surface and internal structure. It helps identify visible defects like cracks, porosity, segregation, or irregularities. 8. Microscopic Examination: By using a microscope, the microscopic examination analyzes the microstructure of the steel billets. It provides insights into grain size, presence of phases, and any abnormalities that may affect the steel's properties. Collectively, these tests guarantee that the steel billets meet the required quality standards and possess the necessary mechanical properties for their intended applications. They ensure the safety, reliability, and performance of steel billets in industries like construction, automotive, aerospace, and manufacturing.

- Q: What are the different types of casting processes used for shaping steel billets?

- There are several different types of casting processes used for shaping steel billets. These processes include: 1. Continuous Casting: This is the most commonly used method for casting steel billets. In this process, molten steel is poured into a water-cooled mold that is continuously moving. As the steel solidifies, it is continuously pulled out of the mold, resulting in a continuous billet. This process is efficient and allows for high production rates. 2. Centrifugal Casting: In this process, molten steel is poured into a rotating mold. The centrifugal force generated by the rotation distributes the molten metal evenly along the mold walls, resulting in a cylindrical billet. This method is used to produce high-quality and defect-free billets. 3. Ingot Casting: This is a traditional method of casting steel billets. In this process, molten steel is poured into a mold and allowed to solidify. The solidified steel, known as an ingot, is then removed from the mold and further processed to obtain the desired shape of the billet. Ingot casting allows for flexibility in terms of billet shape and size. 4. Sand Casting: This process is used for producing large and complex steel billets. It involves creating a mold using a mixture of sand and a binder material. Molten steel is then poured into the mold, and once it solidifies, the mold is removed to reveal the billet. Sand casting allows for the production of custom-shaped billets but is a slower and less precise process compared to others. 5. Investment Casting: Also known as lost-wax casting, this process is suitable for complex and intricate shapes. In investment casting, a wax pattern of the desired billet shape is created. The wax pattern is then coated with a ceramic shell, and the wax is melted out, leaving behind a hollow mold. Molten steel is poured into the mold, and once it solidifies, the ceramic shell is broken to retrieve the billet. Each of these casting processes has its advantages and disadvantages, and the choice of process depends on factors such as the desired billet shape, size, production volume, and quality requirements.

- Q: Can steel billets be used in the production of pipes?

- Yes, steel billets can be used in the production of pipes. Steel billets are semi-finished metal products that can be further processed into various shapes, including pipes. The billets are heated, pierced, and elongated to form seamless pipes or rolled and welded to create welded pipes.

- Q: What are the common heat treatment processes for steel billets?

- Steel billets can undergo several heat treatment processes to modify their mechanical properties, including hardness, strength, and toughness, to meet specific requirements for different applications. One prevalent heat treatment process for steel billets is annealing. This involves heating the steel to a specific temperature and maintaining it at that temperature for a set duration, followed by gradual cooling. Annealing helps alleviate internal stresses in the steel, improve its machinability, and enhance its ductility. Another widely used heat treatment process for steel billets is quenching and tempering. Quenching involves rapidly cooling the steel from a high temperature to room temperature using a liquid or gas medium, like water or oil. This process results in hardened steel with increased strength and hardness. However, the steel becomes brittle after quenching, so it is then tempered by reheating it to a lower temperature and holding it at that temperature for a specific time period. Tempering reduces brittleness and improves the toughness and ductility of the steel. Normalizing is another heat treatment process employed for steel billets. It entails heating the steel to a temperature above its critical transformation temperature and then cooling it in still air. Normalizing helps refine the grain structure of the steel, improve its mechanical properties, and enhance its machinability. Lastly, stress relieving is a process used to reduce internal stresses in steel billets that may have been generated during manufacturing processes such as casting or forging. Stress relieving involves heating the steel to a specific temperature and maintaining it at that temperature for a certain duration, followed by gradual cooling. This process aids in improving dimensional stability and reducing the risk of distortion or cracking in the steel. Overall, these common heat treatment processes for steel billets play a vital role in optimizing the properties and performance of steel for various industrial applications, including automotive, construction, aerospace, and energy sectors.

- Q: How do steel billets contribute to the overall durability of a structure?

- Steel billets contribute to the overall durability of a structure by providing a strong and reliable foundation. These billets are made from high-quality steel and undergo a rigorous manufacturing process, resulting in a dense and uniform material. This ensures that the structure has excellent strength, toughness, and resistance to deformation, which helps it withstand various external forces and stresses. Additionally, the uniformity and consistency of steel billets make them less prone to defects and structural weaknesses, enhancing the overall durability and longevity of the structure.

- Q: What are the different methods of surface inspection for steel billets?

- Steel billets can undergo various methods of surface inspection to identify defects or irregularities. These include visual inspection, magnetic particle inspection, liquid penetrant inspection, ultrasonic inspection, and eddy current inspection. The simplest and most commonly used method is visual inspection, where inspectors visually examine the billet surface for visible defects such as cracks, pits, or irregularities. This method relies on the expertise and experience of the inspector. Magnetic particle inspection involves the use of magnetic fields and particles to detect surface and near-surface defects. By applying a magnetic field and particles to the billet surface, any defects attract particles, making them visible under proper lighting. Liquid penetrant inspection is another method used to detect surface defects. It involves applying a penetrant to the surface, which seeps into defects. After removing excess penetrant, a developer is applied to draw out the penetrant from the defects, making them visible. Ultrasonic inspection uses high-frequency sound waves to detect internal and surface defects. Sound waves are emitted into the billet using a transducer, and the reflected waves are analyzed to identify defects such as cracks, voids, and inclusions. Eddy current inspection is a non-destructive testing method that uses electromagnetic induction to detect surface defects. By moving a probe over the billet surface and passing an alternating current through it, any irregularities or defects disrupt the current flow, which can be detected and analyzed. Each method has its own advantages and limitations, and the choice depends on specific inspection requirements and constraints. Manufacturers utilize these methods to ensure the quality and reliability of steel billets before further processing or use in various applications.

Send your message to us

Prime quality prepainted galvanized steel 695mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords