Prime Q275 85mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

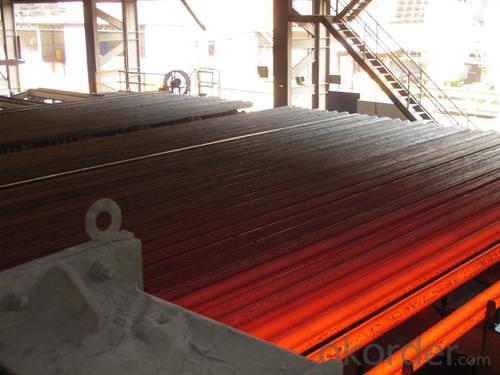

Structure of Prime Q275 85mm Square Alloy Steel Billet

Description of Prime Q275 85mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 85mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 80mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 85mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 85mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What is the cost of a steel billet?

- The cost of a steel billet can change based on several factors including size, grade, and market conditions. Steel billets are semi-finished products used as raw materials for various steel products. The price of a steel billet is typically given per metric ton. To determine the cost, one needs to consider the current market price of steel, which can fluctuate due to factors such as supply and demand, international trade policies, and global economic conditions. Furthermore, the grade of the steel billet can impact the cost since different grades have different levels of purity and specifications. It is crucial to contact steel suppliers or refer to market reports for accurate and current information on the cost of steel billets. Additionally, additional factors like transportation and handling costs may also affect the final price.

- Q: How are steel billets used in the manufacturing of pressure vessels?

- Pressure vessels require steel billets as a necessary part of their manufacturing process. These metal products are in a semi-finished state and are typically made through casting or extrusion. The billets are molded into a solid square or rectangular shape to ensure consistent and uniform material for further processing. To initiate the manufacturing process, the steel billets are heated to a specific temperature, making them more malleable and easier to handle. Once heated, they are placed into a forging machine, where intense pressure and shaping take place. This forging process effectively eliminates any defects or inconsistencies in the billet's structure, resulting in a stronger and more durable material. After the forging stage, the steel billets undergo additional processing using different techniques like rolling or machining. These techniques are employed to achieve the desired dimensions and shape required for pressure vessel fabrication. By refining the billet's surface finish and improving its mechanical properties, these techniques enhance the overall quality of the billet. Once the billets have been shaped and processed, they are cut into smaller sections that serve as the foundation for constructing pressure vessels. These sections are welded together to form the vessel's shell, ensuring a secure and tight seal to contain high-pressure fluids or gases. The use of steel billets in pressure vessel manufacturing is critical due to their superior strength, durability, and resistance to high-pressure environments. The uniformity and consistency of the billets provide a reliable material for fabricating vessels that can endure extreme conditions, guaranteeing the safety and integrity of the contents within. In conclusion, steel billets play a crucial role in the manufacturing of pressure vessels by providing the core components for constructing the vessel's shell. Through a series of heating, forging, and processing techniques, the billets are transformed into robust and enduring sections that are then welded together to form the final vessel. The utilization of steel billets ensures the structural integrity and dependability of pressure vessels, making them suitable for a wide range of industrial applications.

- Q: How are steel billets used in the production of marine components?

- Steel billets are an integral part of the production process for marine components. These components, such as ship propellers, hulls, and offshore structures, require a high level of strength, durability, and corrosion resistance to withstand the harsh conditions of the marine environment. Steel billets are essentially semi-finished products in the form of a solid rectangular shape. They are typically made by casting liquid steel into molds and then allowing it to cool and solidify. These billets are then used as raw material in the manufacturing of various marine components. In the production of marine components, steel billets are first heated to a specific temperature to soften the material. This process, known as hot rolling, allows the billets to be shaped into different forms, such as bars, rods, or sheets, depending on the specific requirement of the component being produced. Once the desired shape is achieved, the steel billets are subjected to further processes like forging, machining, and welding. Forging involves applying pressure to the heated billets to shape them into the desired marine component. Machining is carried out to refine the shape, size, and surface finish of the component, ensuring it meets the required specifications. Welding is used to join different steel billets or sections together to form larger marine components, such as ship hulls. The use of steel billets in the production of marine components offers several advantages. Steel is a strong and durable material that can withstand the extreme forces and conditions encountered in the marine environment. Additionally, steel has excellent corrosion resistance properties, which are essential for marine components exposed to saltwater and other corrosive agents. In conclusion, steel billets play a crucial role in the production of marine components. They serve as the raw material that is shaped, refined, and joined together to create strong, durable, and corrosion-resistant components for ships, offshore structures, and other marine applications.

- Q: Billet heating furnace billet temperature reached, steel will be adhesion

- There are a lot of billet heating furnace manufacturers, not just look at the price and go blind choice, billet heating furnace selection properly, will directly affect the day after work is carried out properly, choose cost-effective equipment is the first choice for users, recommended to look at the video consultation.

- Q: What is the lifespan of a steel billet?

- Several factors can influence the lifespan of a steel billet, including the quality of the steel, storage and usage conditions, and the specific application it is used for. Generally, steel billets are designed to have a lengthy lifespan and can withstand years of use without significant deterioration. Steel billets are typically made from high-quality steel that is engineered to possess exceptional strength, durability, and resistance to corrosion. This ensures that the billet can endure the demands of various industrial processes and applications. In terms of storage and usage conditions, it is crucial to store steel billets in a dry and controlled environment to prevent rust and degradation caused by moisture and other contaminants. Proper handling and transportation are also necessary to avoid any physical damage that could compromise their integrity. The lifespan of a steel billet is also influenced by the specific application it is used for. Some billets are utilized in high-stress applications such as construction, automotive manufacturing, or heavy machinery, which subject them to significant wear and tear. In such cases, the lifespan of the billet may be shorter compared to less demanding applications. In conclusion, with appropriate care, maintenance, and adherence to recommended usage guidelines, a steel billet can have a long lifespan ranging from several years to decades. Regular inspections, maintenance, and replacement of worn or damaged billets are vital to ensure optimal performance and safety in various industries.

- Q: How are steel billets priced in the market?

- Steel billets are typically priced in the market based on various factors such as supply and demand dynamics, production costs, and market conditions. The pricing is influenced by factors such as raw material costs, energy prices, transportation costs, and any applicable taxes or duties. Additionally, market participants consider factors like global economic trends, industry forecasts, and geopolitical events that may impact the overall steel market. Ultimately, steel billet pricing is determined through negotiations between buyers and sellers based on these various factors.

- Q: What are the main challenges in sourcing steel billets?

- The main challenges in sourcing steel billets include fluctuating prices, ensuring quality standards, finding reliable suppliers, dealing with logistics and transportation, and managing the risks associated with international trade and political instability in some steel-producing regions.

- Q: How do steel billets contribute to the manufacturing of construction supplies?

- Steel billets are the primary raw material used in the manufacturing of construction supplies. These billets are heated and then shaped into various forms such as bars, rods, beams, and plates, which are essential components in construction projects. They provide the necessary strength, durability, and structural integrity required for buildings, bridges, and other infrastructure. The versatility and quality of steel billets make them indispensable in the construction industry.

- Q: What is the purpose of using steel billets in manufacturing?

- The purpose of using steel billets in manufacturing is to create a reliable and versatile raw material for various industrial applications. Steel billets are semi-finished products that are produced through the continuous casting or hot rolling process. These solid rectangular or square-shaped bars of steel serve as the building blocks for creating a wide range of steel products. One of the primary purposes of using steel billets is to provide a consistent and high-quality material with specific mechanical properties. Steel, being an alloy of iron and carbon, can be customized by adjusting the carbon content, alloying elements, and heat treatment processes. By controlling these variables during the production of steel billets, manufacturers can ensure that the resulting steel products possess desired characteristics such as strength, hardness, ductility, and corrosion resistance. Furthermore, steel billets allow manufacturers to efficiently shape and form the desired end products. They can be further processed through various techniques such as hot rolling, forging, extrusion, or machining to create different shapes, sizes, and profiles. Steel billets serve as the starting point for the production of a wide range of steel products, including bars, rods, tubes, wire, structural shapes, and even complex components for machinery, automobiles, construction, and infrastructure projects. Additionally, using steel billets in manufacturing offers several advantages. Steel is known for its exceptional strength, durability, and versatility, making it an ideal material for a diverse range of applications. Steel billets provide a cost-effective option for manufacturers as they can be mass-produced and easily transformed into different forms. Moreover, steel is highly recyclable, ensuring a sustainable and environmentally friendly manufacturing process. In summary, the purpose of using steel billets in manufacturing is to provide a consistent and high-quality raw material that can be shaped and processed into various steel products. Steel billets offer the flexibility, strength, and durability required for a wide range of industrial applications, making them an essential component in the manufacturing industry.

- Q: What are the different methods of surface inspection for steel billets?

- There are several methods of surface inspection for steel billets, which are used to identify any defects or irregularities on the surface. These methods include visual inspection, magnetic particle inspection, liquid penetrant inspection, ultrasonic inspection, and eddy current inspection. Visual inspection is the simplest and most commonly used method, where inspectors visually examine the surface of the billets for any visible defects such as cracks, pits, or surface irregularities. This method relies on the expertise and experience of the inspector. Magnetic particle inspection involves the use of magnetic fields and magnetic particles to detect surface and near-surface defects. A magnetic field is applied to the steel billet, and magnetic particles are applied to the surface. If there is a defect, the magnetic particles will be attracted to it, making the defect visible under proper lighting. Liquid penetrant inspection is another method used to detect surface defects. In this method, a liquid penetrant is applied to the surface of the billet. The penetrant seeps into any surface defects, and after a certain amount of time, excess penetrant is removed. A developer is then applied, which draws the penetrant out of the defects, making them visible. Ultrasonic inspection involves the use of high-frequency sound waves to detect internal and surface defects. A transducer is used to emit sound waves into the billet, and the reflected waves are analyzed to identify any defects. This method can detect defects such as cracks, voids, and inclusions. Eddy current inspection is a non-destructive testing method that uses electromagnetic induction to detect surface defects. A probe is moved over the surface of the billet, and an alternating current is passed through it. Any surface irregularities or defects will disrupt the flow of current, which can be detected and analyzed. Each of these methods has its own advantages and limitations, and the choice of method depends on the specific requirements and constraints of the inspection process. By utilizing these different methods, manufacturers can ensure the quality and reliability of steel billets before they are further processed or used in various applications.

Send your message to us

Prime Q275 85mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords