Prime Q275 80mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

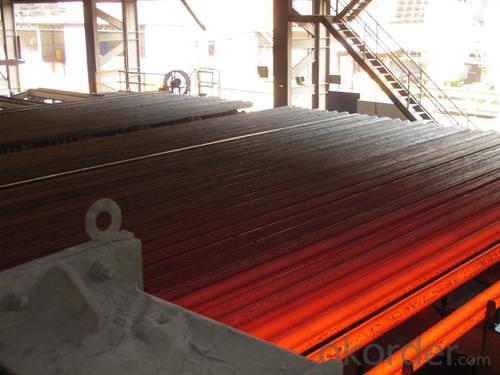

Structure of Prime Q275 80mm Square Alloy Steel Billet

Description of Prime Q275 80mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 80mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 80mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

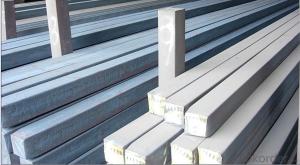

Specifications of Prime Q275 80mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 80mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the manufacturing of slabs?

- Steel billets are used in the manufacturing of slabs by being heated and then rolled into a flat shape. The billets act as the starting material for the slab production process, undergoing various treatments and forming operations to achieve the desired dimensions and properties of the final slab.

- Q: If the casting speed is not steady, what will happen to the billet?

- Secondly, the speed of cutting is unstable, and the cut rate will be reduced.

- Q: What are the different surface defects in steel billets?

- There are several different types of surface defects that can be found in steel billets. These defects can occur during the manufacturing process or as a result of handling and transportation. Some common surface defects in steel billets include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of steel billets during the heating and rolling process. It appears as a rough, flaky coating and can negatively affect the surface quality and appearance of the billet. 2. Cracks: Cracks can occur on the surface of steel billets due to various reasons such as improper cooling, excessive rolling pressure, or high levels of stress during handling. These cracks can range from minor surface cracks to more severe deep cracks, compromising the integrity and strength of the billet. 3. Lamination: Lamination defects occur when there are layers or sheets of non-metallic inclusions within the steel billet. These layers can cause weak spots in the billet, making it susceptible to failure under stress. 4. Pitting: Pitting is the formation of small, localized cavities or depressions on the surface of the steel billet. It can be caused by various factors such as corrosion, improper cleaning, or exposure to corrosive environments. 5. Slivers: Slivers are thin, elongated pieces of steel that protrude from the surface of the billet. They can be caused by improper cutting or shearing operations, which can result in sharp edges and potential safety hazards. 6. Rolled-in scale: Rolled-in scale refers to the presence of scale that has been embedded into the surface of the billet during the rolling process. This can affect the surface finish and may require additional cleaning or surface treatment. 7. Surface scratches: Surface scratches are shallow marks or abrasions on the surface of the steel billet. They can occur during handling, transportation, or as a result of contact with abrasive surfaces. While they may not significantly impact the structural properties of the billet, they can affect the aesthetics and may require further treatment or polishing. It is important to identify and address these surface defects in steel billets to ensure the quality and performance of the final product. Regular inspection, proper handling, and appropriate surface treatment techniques can help minimize these defects and improve the overall quality of the steel billets.

- Q: What is the average density of a steel billet?

- The density of a steel billet can differ based on its specific grade and composition. On average, a steel billet has a density ranging from approximately 7,800 to 8,050 kilograms per cubic meter (kg/m³). This density is higher than that of numerous other materials, rendering steel a dense and weighty substance. When determining the weight, volume, and overall structural properties of a steel billet, its density plays a vital role.

- Q: How are steel billets stored to prevent corrosion?

- Steel billets are typically stored in covered warehouses or under protective tarps to shield them from moisture and exposure to air. Additionally, a corrosion inhibitor such as a rust-preventive coating or oil may be applied to the surface of the billets to create a barrier against oxidation.

- Q: What is the chemical composition of steel billets?

- Steel billets typically contain iron as the primary element, along with varying amounts of carbon, manganese, silicon, sulfur, and phosphorus, which make up its chemical composition. The specific grade and intended use of the steel billets determine the exact composition, which may vary. Carbon, in small quantities ranging from 0.02% to 0.5%, is included to enhance the steel's strength and hardness. Manganese is commonly added to improve toughness and hardenability, while silicon aids in deoxidizing the metal and increasing its strength. Sulfur and phosphorus, impurities that can adversely affect the steel's mechanical properties, are typically kept at low levels. Furthermore, chromium, nickel, molybdenum, and other elements may be added in small amounts to enhance specific properties such as corrosion resistance or high-temperature strength.

- Q: How do steel billets contribute to the manufacturing of sports gear?

- Steel billets are an essential raw material used in the manufacturing of sports gear because they provide the strength and durability needed to withstand the rigorous demands of various sports activities. These billets serve as the foundation for shaping and forming different components of sports gear, such as shafts, frames, and blades, ensuring that the final products are robust, long-lasting, and capable of delivering optimal performance on the field or court.

- Q: How are steel billets used in the production of structural components?

- Steel billets are used in the production of structural components by being heated and molded into desired shapes such as beams, columns, and plates. These billets serve as the starting material, which is then further processed through rolling, forging, or extrusion to create strong and durable structural components used in various industries such as construction, automotive, and aerospace.

- Q: Can steel billets be extruded into different shapes?

- Yes, steel billets can be extruded into different shapes. Extrusion is a metalworking process where a material, in this case, a steel billet, is forced through a die to create a desired shape. The billet is heated to a specific temperature to make it malleable and then pushed through the die using a hydraulic or mechanical press. This process allows for the creation of a wide range of shapes, such as rods, bars, tubes, profiles, and even complex geometries. Extrusion is commonly used in the manufacturing industry to produce various steel products for construction, automotive, aerospace, and other applications.

- Q: How do steel billets contribute to the overall safety of a product?

- Steel billets contribute to the overall safety of a product by providing a strong and durable foundation. They are used as raw material in the manufacturing of various products, including construction materials, automotive parts, and machinery. The high strength and structural integrity of steel billets ensure that the end products are able to withstand heavy loads, extreme conditions, and potential hazards, thus enhancing safety and reliability.

Send your message to us

Prime Q275 80mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords