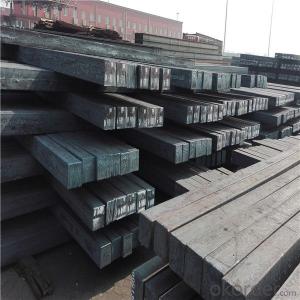

Prime hot rolled steel square billet mill price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17145 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

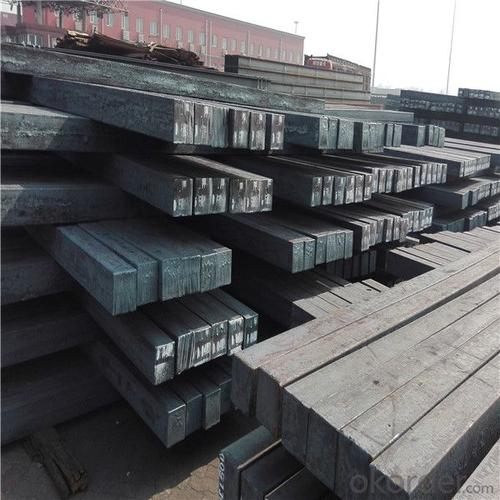

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel

billets are also known for their malleability and ductility, especially when exposed to varying temperatures

during shaping and molding.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the main factors affecting the thermal conductivity of steel billets?

- The thermal conductivity of steel billets is influenced primarily by several factors. Firstly, the chemical composition of the steel plays a crucial role in determining its thermal conductivity. Elements like carbon, manganese, and silicon can impact the crystal structure and atom arrangement within the steel, thereby affecting its ability to conduct heat. Generally, steels with higher carbon content have lower thermal conductivity due to increased impurities and non-conductive carbide formation. Secondly, the microstructure of the steel also affects its thermal conductivity. Heat conduction in steel happens through lattice vibrations called phonons. Grain boundaries, dislocations, and other defects within the microstructure can hinder phonon movement, resulting in reduced thermal conductivity. Conversely, a more uniform and fine-grained microstructure enhances thermal conductivity. Furthermore, the temperature of the steel billet significantly impacts its thermal conductivity. As the temperature rises, the thermal conductivity of steel generally decreases due to increased scattering of phonons by lattice vibrations and higher thermal resistance. Another factor influencing the thermal conductivity of steel billets is their physical dimensions, specifically cross-sectional area and length. A larger cross-sectional area leads to higher thermal conductivity as there is more space for heat transfer. Similarly, longer billets tend to have lower thermal conductivity due to increased distance for heat conduction. Lastly, the presence of impurities and alloying elements in the steel can also affect its thermal conductivity. For instance, alloying elements like nickel, chromium, and copper can alter the crystal structure and lattice vibrations, thereby influencing the thermal conductivity of the steel billet. In conclusion, the thermal conductivity of steel billets is influenced by factors such as chemical composition, microstructure, temperature, physical dimensions, and the presence of impurities and alloying elements. Understanding these factors is crucial in various industrial applications where heat transfer and thermal management are critical.

- Q: Can steel billets be used in the production of railway tracks?

- Yes, steel billets can be used in the production of railway tracks. Steel billets are commonly used as raw material for manufacturing various steel products, including railway tracks. The billets are first heated and then rolled into shape to create the required profile for the tracks. This process ensures the tracks have the necessary strength, durability, and dimensional accuracy to withstand the heavy loads and constant usage in railway operations.

- Q: How are steel billets sheared into smaller sections?

- Steel billets are sheared into smaller sections using a hydraulic shear machine. The machine applies a strong force to the billet, causing it to be cut through its cross-section, resulting in multiple smaller sections.

- Q: What is the role of steel billets in the production of sheet metal?

- The production of sheet metal heavily relies on steel billets, which serve as the primary raw material. These billets are essentially solid bars of steel, typically rectangular or square in shape, and are produced through casting or hot rolling. Depending on the specific requirements of the sheet metal being manufactured, steel billets are produced in various sizes and lengths. To begin the production process, the steel billets are heated to a high temperature and then passed through a series of rolling mills. This rolling process is aimed at reducing the thickness of the billets and increasing their length. By applying pressure to the billets, they elongate and become thinner. This continuous rolling process is repeated multiple times until the desired thickness is achieved. Once the steel billets have been transformed into thin sheets, further processing is carried out to obtain the final sheet metal product. This may involve additional steps such as cutting, trimming, and surface treatments to enhance both the appearance and properties of the sheet metal. Steel billets are highly favored in the production of sheet metal due to their exceptional mechanical properties. Steel is renowned for its strength, durability, and malleability, making it an ideal material for sheet metal applications. By utilizing steel billets, the resulting sheet metal products possess these desirable properties. To summarize, steel billets serve as the starting point in the production of sheet metal. Through heating and rolling processes, the billets are transformed into thin sheets of steel, which are then further processed to create the final sheet metal products. The use of steel billets is crucial in ensuring the production of sheet metal with superior mechanical properties, making it an indispensable component in the manufacturing industry.

- Q: What is the global production and consumption of steel billets?

- Steel billets play a crucial role in the worldwide construction and manufacturing sectors, with their production and consumption being of great significance. When it comes to manufacturing, several countries are major players in the production of steel billets. China, the largest producer of steel globally, contributes significantly to the global steel billet production. Other notable producers include India, Japan, Russia, the United States, and Turkey. These countries have well-established steel industries and infrastructure to support large-scale production. The consumption of steel billets is driven by the demand for steel products in various sectors. The construction and infrastructure development sectors are the primary drivers, as steel is widely used in the construction of buildings, bridges, roads, and other structures. The automotive industry is also a major consumer, utilizing steel billets for manufacturing automobile parts and components. Providing an exact figure for global steel billet production and consumption is challenging due to the ever-changing market dynamics and varying industry reports. However, it is estimated that global steel production exceeded 1.8 billion metric tons in 2020, with a significant portion of this production in the form of steel billets. The consumption of steel billets is closely linked to overall steel demand, which is influenced by economic growth, infrastructure development, industrial activity, and construction projects worldwide. In conclusion, the global production and consumption of steel billets are of great significance, highlighting the importance of steel as a vital material in various industries. The continuous growth in infrastructure development and industrialization globally is expected to further drive the production and consumption of steel billets in the years to come.

- Q: What are the main factors that determine the sustainability of steel billets production?

- The main factors that determine the sustainability of steel billets production include the source of raw materials, energy efficiency in the production process, waste management, carbon emissions, water usage, and adherence to environmental regulations. Additionally, the implementation of sustainable practices such as recycling, reducing greenhouse gas emissions, and promoting responsible sourcing contribute to the overall sustainability of steel billets production.

- Q: How are steel billets tested for mechanical properties?

- Steel billets are tested for mechanical properties using various methods to ensure their quality and suitability for specific applications. One common method is the tensile test, which involves pulling a small sample from the billet and subjecting it to a gradually increasing tensile force until it fractures. This test helps determine important mechanical properties such as ultimate tensile strength, yield strength, and elongation. Another method used is the hardness test, which measures the resistance of the billet's surface to indentation. This test provides information about the billet's hardness, which is crucial for assessing its ability to withstand wear and deformation. Additionally, the impact test is performed to evaluate the billet's toughness and ability to absorb energy. This involves striking a standardized sample with a pendulum and measuring the energy absorbed during fracture. The impact test is particularly important for applications where the steel billet is subjected to sudden loads or impacts. To assess the billet's ability to resist deformation, the compression test is employed. In this test, the billet is subjected to a compressive force until it deforms or fractures. The results obtained from this test help determine the billet's compressive strength and deformation characteristics. Furthermore, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are used to detect any internal defects or irregularities in the billet. These methods involve the use of specialized equipment to examine the billet's internal structure and identify any flaws that may compromise its mechanical properties. Overall, steel billets undergo a comprehensive range of tests to ensure their mechanical properties meet the required standards. These tests help guarantee the quality and reliability of the billets, enabling them to be used in various industries such as construction, automotive, and manufacturing.

- Q: How do steel billets contribute to the energy sector?

- Steel billets are an essential component in the energy sector for various reasons. Firstly, they are used in the construction of power plants and energy infrastructure. Steel billets are often used to fabricate structures such as beams, columns, and support systems that are critical for the stability and safety of these facilities. These structures provide the necessary framework to house generators, turbines, and other equipment required for energy production. Moreover, steel billets are used in the manufacturing of pipelines and storage tanks for the transportation and storage of various energy resources. Whether it is oil, natural gas, or even renewable energy sources like hydrogen, steel billets are used to create durable and reliable pipeline systems that can withstand high pressures and harsh environmental conditions. Similarly, steel billets are used in the construction of storage tanks that hold energy resources, ensuring their safe storage and easy access when needed. Steel billets also play a vital role in the production of wind turbines. The towers of wind turbines are often made from steel billets due to their high strength and durability. These towers support the blades and nacelle, which house the generator and other components. The ability of steel billets to withstand extreme weather conditions and support the weight of the turbine is crucial for the efficient and reliable generation of wind energy. Furthermore, steel billets are used in the manufacturing of equipment and machinery utilized in the extraction and exploration of energy resources. For example, drilling rigs and equipment used in oil and gas exploration are often constructed using steel billets due to their high tensile strength and resistance to corrosion. This enables efficient and safe drilling operations, contributing to the overall energy production process. In conclusion, steel billets contribute significantly to the energy sector by providing the necessary infrastructure, pipelines, storage tanks, and equipment required for energy production, transportation, and exploration. Their strength, durability, and versatility make them an essential component in the construction and functioning of power plants, pipelines, wind turbines, and various other energy-related applications.

- Q: What are the common heat treatment processes for steel billets?

- There are several common heat treatment processes for steel billets. These processes are used to alter the mechanical properties of the steel, such as its hardness, strength, and toughness, to meet specific requirements for different applications. One of the most common heat treatment processes for steel billets is annealing. This involves heating the steel to a specific temperature and holding it at that temperature for a certain period of time, followed by slow cooling. Annealing helps to relieve internal stresses in the steel, improve its machinability, and enhance its ductility. Another commonly used heat treatment process for steel billets is quenching and tempering. Quenching involves rapidly cooling the steel from a high temperature to room temperature using a liquid or gas medium, such as water or oil. This process results in a hardened steel with increased strength and hardness. However, the steel becomes brittle after quenching, so it is then tempered by reheating it to a lower temperature and holding it at that temperature for a specific duration. Tempering reduces the brittleness and improves the toughness and ductility of the steel. Normalizing is another heat treatment process used for steel billets. It involves heating the steel to a temperature above its critical transformation temperature and then cooling it in still air. Normalizing helps to refine the grain structure of the steel, improve its mechanical properties, and enhance its machinability. Lastly, there is also the process of stress relieving, which is used to reduce internal stresses in the steel billets that may have been generated during manufacturing processes such as casting or forging. Stress relieving involves heating the steel to a specific temperature and holding it at that temperature for a certain period of time, followed by slow cooling. This process helps to improve the dimensional stability and reduce the risk of distortion or cracking in the steel. Overall, these common heat treatment processes for steel billets play a crucial role in optimizing the properties and performance of the steel for various industrial applications, ranging from automotive and construction to aerospace and energy sectors.

- Q: What are the advantages of using steel billets in manufacturing?

- There are several advantages of using steel billets in manufacturing processes. Firstly, steel billets offer exceptional strength and durability. Steel is known for its high tensile strength, making it ideal for applications that require heavy loads or resistance to wear and tear. This strength ensures that products made from steel billets are long-lasting and can withstand harsh conditions, increasing their lifespan and reducing the need for frequent replacements. Secondly, steel billets are highly versatile. They can be easily molded and shaped into various forms, allowing manufacturers to create a wide range of products with different designs and specifications. This versatility makes steel billets suitable for a diverse range of industries, including construction, automotive, machinery, and appliances. Furthermore, steel billets are cost-effective. Steel is one of the most affordable and readily available materials in the manufacturing industry. Its widespread availability ensures a steady supply, reducing the cost of production. Additionally, steel's durability minimizes maintenance and replacement expenses, saving money in the long run. Another advantage of using steel billets is their eco-friendliness. Steel is a highly recyclable material, and using steel billets in manufacturing promotes sustainability. Recycling steel reduces the need for mining raw materials, conserves energy, and decreases carbon emissions. Therefore, steel billets contribute to a greener manufacturing process and support environmental conservation efforts. Lastly, steel billets offer excellent performance characteristics. Steel has exceptional thermal and electrical conductivity properties, making it suitable for applications that require heat dissipation or electrical conduction. Additionally, steel is resistant to corrosion, rust, and fire, adding an extra layer of protection to products manufactured using steel billets. In conclusion, the advantages of using steel billets in manufacturing are its strength and durability, versatility, cost-effectiveness, eco-friendliness, and exceptional performance characteristics. These advantages make steel billets a preferred choice for various industries, ensuring high-quality products that withstand the test of time.

Send your message to us

Prime hot rolled steel square billet mill price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17145 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords