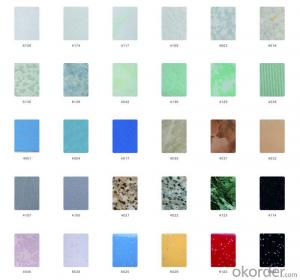

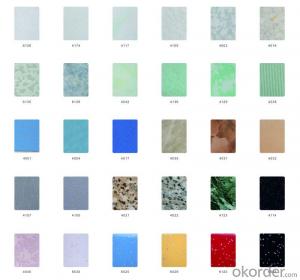

Pressure-type color plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Contour colored plate makes use of color coated steel, by rolling and bending into a variety of wave-type pressured plate, which is applies to industrial and civil buildings, warehouses, special construction, the roof of large span steel structure housing, walls and interior and exterior decoration. It has light weight, high strength, rich colors, earthquake proof, fireproof, rainproofand and long life. In addition, it can be used easily. maintenance-free has been widely used. Or cold-rolled steel sheet by cold forming of steel. Organic coated steel sheet (or color steel), galvanized sheet steel, anti-corrosion sheet steel (including asbestos asphalt layer) or other thin steel plate and so on. Pressure plate has a flat, light weight, high strength, good seismic performance, construction, fast, beautiful shape, etc., it is good building material and components, mainly for the building envelope, floor, can also be used for other structures.

Depending on the use of functional requirements, contour plate can be pressed into a wave, hyperbolic wave, rib-shaped, V-shaped, reinforced type. Commonly used for roofing and wall thickness of 0.4 to 1.6 mm for load-bearing floor or when the thickness of the silo 2 to 3 mm or more. Wave height is generally 10 to 200 mm. When not stiffening, its high-thickness ratio should be controlled at 200 or less. When using a long pass roof, the slope can be 2 to 5%, the deflection does not exceed l/300 (l for the calculation of span).

Thin pressure plate due to the original panel, anti-corrosion coating directly affects the quality of life, in order to meet the requirements of processing and rust-proof, coated steel basis having the relevant provisions of the inspection. Thin steel plate under normal circumstances the requirement can also be based, the pressure-type anti-rust paint and then painted, or stainless steel sheet of the original board. Pressure plate used for industrial plant roof, siding, in the general case of no insulation requirements, per square meter of steel about 5 to 11 kg. A thermal insulation requirements, the available mineral wool board, glass wool, foam and other materials for insulation. Combination of pressure plate made of composite slabs and concrete, can save the template can be used as load-bearing structure of wood. At the same time to strengthen the plate with the concrete binding, should be pre-welded on the plate or the suppression of two-way stud stiffeners.

nto the 21st century, high-speed stable development of China's national economy, and color coated steel sheeting from the general industrial buildings around the large, public buildings, such as airport terminals, railway stations, stadiums, concert halls, large theaters, the 2008 Olympic Games venues. Building roof, floor and wall board type power and connect more reasonable, more scientific construction methods like performance more galvanized plate, aluminum-magnesium-manganese alloy plate, titanium plate, stainless steel, etc. R & D, greatly enhanced the level of applied technology of the subtypes metal plate. Board structure and standards undercut structure, the second generation of the pressure plate of the fastening structure and fasteners hidden connections; CLOSED the Cored The existing mature application; coating plate and pressure plate (substrate) to increase the aluminum plate, galvanized aluminum varieties, coated sheet and partial polyvinyl fluoride (PVDF) coated plates. | ||

| Sample Availability | ||

- Q: How are steel structures designed to provide adequate natural lighting?

- Steel structures are designed to provide adequate natural lighting through the strategic placement of windows, skylights, and transparent or translucent materials in the building envelope. These design elements maximize the entry of natural light into the space, reducing the need for artificial lighting during the day. Additionally, the use of reflective surfaces and light-colored finishes on the interior helps distribute and amplify the natural light, creating a brighter and more comfortable environment.

- Q: What is the role of steel in automotive manufacturing plants?

- The role of steel in automotive manufacturing plants is crucial as it serves as the primary material for building the structural components of vehicles. Steel is used in various forms, including sheets, beams, bars, and tubes, and it offers exceptional strength, durability, and versatility. One of the primary applications of steel in automotive manufacturing is in the body and chassis construction. Steel's high tensile strength allows it to withstand the forces and impacts that a vehicle may encounter during its lifespan. It provides rigidity and structural integrity to the vehicle, ensuring passenger safety in the event of a collision or rollover. Steel is also used extensively in the manufacturing of engine components, such as crankshafts, connecting rods, and cylinder heads. These parts require high strength and heat resistance, which steel can provide. Additionally, steel is used in the production of suspension systems, brake components, and exhaust systems, where its strength and resistance to corrosion are highly valued. Furthermore, steel plays a vital role in the manufacturing of automotive body panels. It is often used for outer panels like doors, hoods, and roofs due to its ability to be shaped into complex forms and its resistance to dents and scratches. Steel's malleability allows manufacturers to create aesthetically appealing designs while maintaining the necessary safety standards. Moreover, the use of steel in automotive manufacturing plants offers economic benefits. Steel is widely available, relatively inexpensive, and can be easily recycled, making it a sustainable choice. Its widespread use also allows for efficient mass production, reducing manufacturing costs and ultimately making vehicles more affordable for consumers. In conclusion, steel is an indispensable material in automotive manufacturing plants. Its strength, durability, versatility, and cost-effectiveness make it an ideal choice for building the structural components of vehicles, ensuring safety, performance, and aesthetic appeal.

- Q: How are steel structures used in marine and offshore applications?

- Due to their strength, durability, and ability to withstand harsh environmental conditions, steel structures find extensive use in marine and offshore applications. These structures are specifically designed to endure extreme weather, corrosion, and the dynamic forces imposed by waves and currents. In marine applications, steel structures, such as ship hulls, bulkheads, and decks, fulfill two essential functions: providing structural support and ensuring the vessel's integrity. The selection of steel is based on its high tensile strength, which enables ships to bear heavy loads and withstand the stresses encountered during navigation. Moreover, steel's resistance to corrosion makes it well-suited for prolonged exposure to saltwater and other corrosive elements. Offshore applications also greatly benefit from the use of steel structures. Platforms, including oil rigs and wind turbines, frequently employ steel due to its strength and ability to withstand the harsh offshore environment. Steel is utilized in constructing the platform's substructure, encompassing the legs or piles that anchor it to the seabed. These steel structures guarantee stability and support for the platform, ensuring its safe operation even in turbulent seas. Furthermore, steel structures play a crucial role in the construction of offshore pipelines and underwater infrastructure. Steel pipes are commonly utilized for the transportation of oil, gas, and other fluids over considerable distances beneath the sea. These pipelines are meticulously designed to resist high pressures and environmental stresses, ensuring the secure and efficient transport of resources. In summary, the strength, durability, and resistance to harsh conditions exhibited by steel structures make them indispensable in marine and offshore applications. They provide vital support and stability for vessels, platforms, pipelines, and other infrastructure, ensuring the safe and efficient operation of these systems in challenging marine environments.

- Q: What are the design considerations for steel structures in historical preservation projects?

- When designing steel structures for historical preservation projects, several key considerations need to be taken into account. Firstly, the design should aim to seamlessly blend the new steel elements with the existing historical fabric, ensuring they do not detract from the overall aesthetic and character of the structure. Additionally, any alterations or additions made with steel should be reversible, allowing for future modifications or restorations without causing damage to the original building. The choice of materials and finishes should closely match the original elements to maintain visual harmony. Structural integrity and stability are also crucial factors, as the new steel elements should be able to adequately support the load while preserving the historical structure's original design intent. Lastly, the design should align with local preservation guidelines and regulations to ensure the project is in compliance with historic preservation standards.

- Q: What are the advantages of using steel as a construction material for building structures?

- There are several advantages of using steel as a construction material for building structures. First and foremost, steel is known for its exceptional strength and durability. It has a high strength-to-weight ratio, meaning it can withstand heavy loads without buckling or collapsing. This makes it an ideal choice for constructing tall and large buildings, bridges, and other structures that require significant structural integrity. Additionally, steel is highly resistant to various environmental factors. It is not susceptible to rot, termites, or mold, unlike wood or other organic materials. Steel is also fire-resistant, which enhances the safety of the building by slowing down the spread of fire and providing more time for evacuation. Another advantage of steel is its versatility in design. It can be easily molded and shaped into different forms, allowing architects and engineers to create intricate and unique structures. Steel can be fabricated off-site and then assembled on-site, reducing construction time and labor costs. Moreover, steel is a sustainable and eco-friendly material. It is 100% recyclable, meaning it can be reused without losing its properties. This helps to reduce waste and conserve natural resources. Additionally, the energy required to produce steel has significantly reduced over the years, making it a more energy-efficient option compared to other construction materials. Furthermore, steel structures are known for their longevity. Steel has a long lifespan and requires minimal maintenance. It does not warp, crack, or shrink over time, ensuring the structural stability of the building for decades. This reduces the need for frequent repairs or replacements, saving both time and money in the long run. In conclusion, the advantages of using steel as a construction material for building structures are its strength, durability, resistance to environmental factors, versatility in design, sustainability, and longevity. These factors make steel an excellent choice for a wide range of construction projects, providing safety, efficiency, and cost-effectiveness.

- Q: How are steel structures used in the construction of research and development facilities?

- Steel structures are commonly used in the construction of research and development facilities due to their numerous advantages. Steel is a versatile and durable material that allows for large and open spaces, enabling the flexibility required for research and development activities. It provides high strength, which is crucial for accommodating heavy equipment and machinery. Additionally, steel structures are resistant to fire, corrosion, and pests, ensuring the safety and longevity of the facility. Furthermore, steel construction allows for faster and more efficient building processes, reducing construction time and costs. Overall, steel structures play a vital role in providing the necessary infrastructure for research and development facilities.

- Q: How are steel structures designed to withstand snow loads?

- The strength and stability of steel structures are ensured by a combination of factors when it comes to withstanding snow loads. First and foremost, the design of the steel structure takes into consideration the expected snow loads in the specific location where it will be erected. This involves assessing factors such as the intensity, duration, and wind speed and direction, which can impact how the snow is distributed on the structure. Moreover, engineers employ specific design codes and standards that outline the minimum requirements for snow load design. These codes offer guidance on determining the magnitude of the snow load that the structure should be designed to handle. For instance, in the United States, the International Building Code (IBC) specifies snow load requirements based on the structure's importance and the snow load zone of the location. Once the snow load requirements are established, engineers utilize various load combinations and design methods to calculate the forces exerted by the snow load on the structure. This includes taking into account the weight of the snow itself, as well as any potential impact or drift effects caused by wind or other factors. These calculations aid in determining the necessary strength and stability of the structure to resist the snow loads. To further enhance the ability of the steel structure to withstand snow loads, engineers may incorporate additional design elements such as the slope and pitch of the roof, which facilitate the easy shedding of snow. They may also include features like snow guards or snow fences to prevent excessive snow accumulation in specific areas of the structure. In summary, ensuring the ability of steel structures to withstand snow loads involves a thorough analysis of the expected snow loads, adherence to design codes and standards, and implementation of appropriate design features. This guarantees that the structure can safely support the weight of the snow and maintain its structural integrity under varying snow load conditions.

- Q: How are steel structures designed to accommodate electrical and data systems?

- Steel structures are designed to accommodate electrical and data systems through various methods. This includes the incorporation of dedicated conduits, cable trays, and raceways within the steel framework to ensure proper routing and protection of electrical and data cables. Additionally, steel structures are designed with sufficient load-bearing capacity to support the weight of these systems, and provisions are made for grounding and bonding to ensure electrical safety. Overall, the design of steel structures takes into account the specific requirements of electrical and data systems to enable their seamless integration and functionality within the building.

- Q: What are the advantages of using lightweight steel structures?

- There are several advantages of using lightweight steel structures in various construction projects. Firstly, lightweight steel structures provide a high strength-to-weight ratio, meaning they can offer significant structural support while being lighter than traditional building materials such as concrete or wood. This allows for more flexibility in design and construction, as the reduced weight of the steel components makes it easier to transport and handle on-site. Secondly, lightweight steel structures are highly durable and resistant to various environmental factors such as corrosion, fire, and pests. Steel is known for its robustness and longevity, ensuring that the structure will remain stable and secure for an extended period. This durability also leads to lower maintenance costs over time. Additionally, using lightweight steel structures can result in faster construction times and reduced labor costs. The prefabricated nature of steel components allows for efficient assembly and installation, minimizing the time spent on-site. As a result, projects can be completed more quickly, leading to cost savings for both contractors and clients. Furthermore, steel structures are eco-friendly and sustainable. Steel is a highly recyclable material, and using lightweight steel structures can contribute to reducing waste and carbon emissions. Additionally, steel is energy-efficient, as it can be easily insulated, reducing heating and cooling costs in buildings. Lastly, lightweight steel structures offer design flexibility and adaptability. Steel can be easily shaped and molded into various forms, allowing architects and designers to create unique and aesthetically pleasing structures. Moreover, steel structures can be modified or expanded in the future, making them adaptable to changing needs or requirements. In summary, the advantages of using lightweight steel structures include their high strength-to-weight ratio, durability, resistance to environmental factors, faster construction times, reduced labor costs, eco-friendliness, and design flexibility. These advantages make lightweight steel structures a preferred choice for a wide range of construction projects.

- Q: How are steel structures designed to accommodate for future expansion or modifications?

- Steel structures can be designed with flexibility in mind to accommodate future expansion or modifications. This can be achieved through the use of modular construction techniques, which allow for easy addition or removal of structural elements. Additionally, designers can incorporate extra load-bearing capacity into the initial design, enabling the structure to support additional loads in the future. Expansion joints can also be included to provide flexibility and accommodate movement. Overall, steel structures are designed with the foresight to adapt and accommodate future changes.

Send your message to us

Pressure-type color plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords