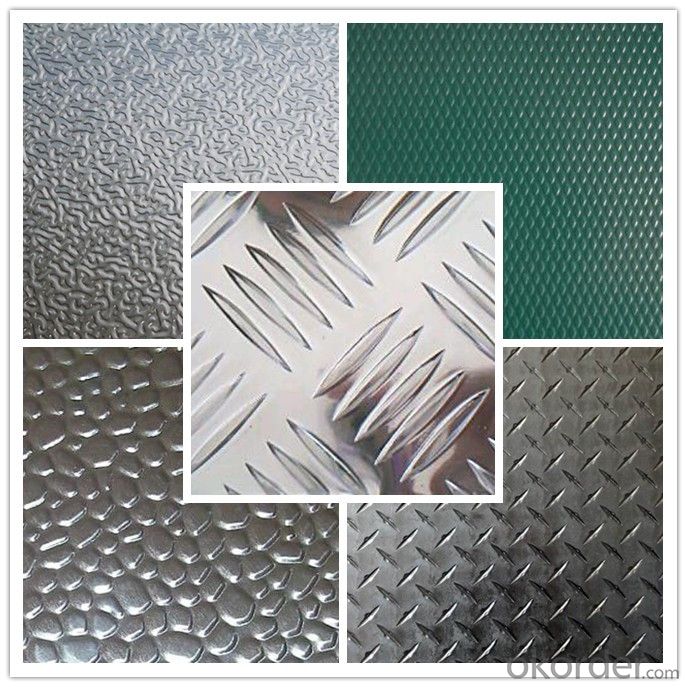

Powder Coated Embossed Aluminum Sheet Plate with Low Noise - 5 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Embossed Aluminum Sheet Plate With Low Noise - 5 Bar

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of Embossed Aluminum Sheet Plate With Low Noise - 5 Bar

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What does aluminum plate mean?

- Dear, 1070 and 1060 are not the specifications of aluminum sheet, but the type of aluminum plateThe model is used to distinguish the different components of aluminum, the model is different, the composition of aluminum is differentShenzhen Cheng Cheng metal - - - --- aluminum plate - -

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- Yes, 101 aluminum sheets are suitable for decorative purposes. These sheets are made of high-quality aluminum alloy, which provides a sleek and polished appearance. They have excellent corrosion resistance and are easy to clean, making them ideal for use in decorative applications. Additionally, 101 aluminum sheets can be easily cut and shaped, allowing for creative designs and customization. Whether it's for interior or exterior decoration, these sheets can be used for various purposes such as wall cladding, signage, furniture accents, and more. With their durability and aesthetic appeal, 101 aluminum sheets are a great choice for adding a touch of elegance to any space.

- Q: How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Yes, aluminum sheets are suitable for food processing conveyor systems. Aluminum is a popular choice for conveyor systems in the food processing industry due to its numerous advantages. Firstly, aluminum is lightweight yet strong, making it ideal for conveyor systems that require frequent movement and transportation of food products. Its lightweight nature allows for easy installation, maintenance, and modification of conveyor systems, while its strength ensures the durability and longevity of the equipment. Secondly, aluminum is corrosion-resistant, which is crucial in food processing environments where exposure to moisture, chemicals, and food acids is common. This resistance to corrosion ensures that the conveyor system remains hygienic and free from contamination, meeting the strict food safety standards required in the industry. Furthermore, aluminum is non-toxic, making it a safe material for food handling and contact. It does not react with food or release any harmful substances, ensuring the integrity and safety of the food being processed on the conveyor system. Moreover, aluminum is easy to clean and maintain, which is essential in food processing environments where hygiene is of utmost importance. The smooth and non-porous surface of aluminum sheets allows for easy removal of food particles, grease, and other contaminants, reducing the risk of bacterial growth and cross-contamination. In summary, due to its lightweight, corrosion-resistant, non-toxic, and easy-to-clean properties, aluminum sheets are highly suitable for food processing conveyor systems. They provide a reliable and efficient means of transporting food products while ensuring the highest standards of hygiene and food safety.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: Can aluminum sheets be used in cryogenic applications?

- Yes, aluminum sheets can be used in cryogenic applications. Aluminum has excellent thermal conductivity, low density, and good strength, making it suitable for use in cryogenic environments where extremely low temperatures are involved. Additionally, aluminum's resistance to corrosion and its ability to maintain its mechanical properties at cryogenic temperatures make it a popular choice for various cryogenic applications, such as in the aerospace industry and in cryogenic storage systems.

- Q: Are aluminum sheets easy to clean?

- It is generally a simple task to clean aluminum sheets. Aluminum, being a non-porous material, has the advantage of not readily absorbing liquids or stains. Consequently, it is fairly easy to remove dirt, dust, or spills from the surface of aluminum sheets with the use of a moist cloth or sponge. Furthermore, aluminum's resistance to rust and corrosion means that no special cleaning agents or treatments are necessary. However, it is worth noting that abrasive cleaners or scrubbing pads should be avoided as they have the potential to scratch the aluminum surface. In summary, by regularly maintaining and employing proper cleaning techniques, aluminum sheets can be kept clean and in excellent condition for an extended period of time.

- Q: Can 101 aluminum sheets be welded?

- Absolutely, welding is indeed possible with 101 aluminum sheets. The 101 aluminum alloy, renowned for its superb weldability, is extensively employed in welding applications. However, it is crucial to emphasize the significance of employing appropriate welding techniques and equipment to achieve a triumphant weld.

- Q: Can aluminum sheets be etched or engraved?

- Indeed, it is possible to etch or engrave aluminum sheets. The process entails removing a portion of the material from the surface by utilizing acid or a laser with substantial power. This technique allows for the creation of detailed designs, patterns, or even textual elements on the aluminum sheet. The applications for etching or engraving are diverse, including signage, decorative items, and industrial components. To achieve the desired appearance, color or other finishes can be added to further enhance the resulting design on the aluminum sheet.

Send your message to us

Powder Coated Embossed Aluminum Sheet Plate with Low Noise - 5 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords