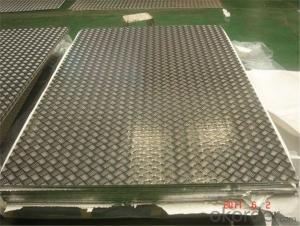

032 Aluminum Diamond Plate Sheets - Embossed Aluminum Sheet Five Bars Aluminum Sheet 0.1~5mm 3 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

5 bar embossed aluminum sheet :

1.Thickness:0.8-12mm

2.Width:300-1900mm

3.factory price

4.ISO & SGS

0.1~5mm 3 bar embossed aluminum sheet five bars aluminum sheet

Product Description

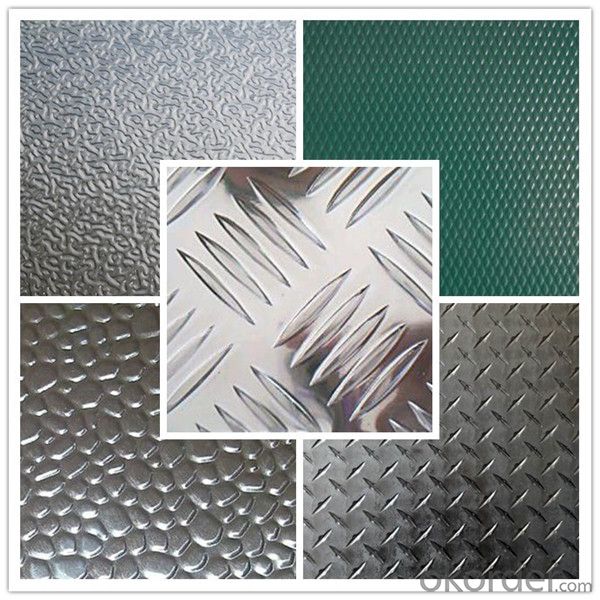

Embossed aluminum sheet | |

Alloy grade | 1050,1060,1100,3003,3004,3105,5052,5005,5754,5083,6061,6063 etc |

Temper | 0,H12,H14,H16,H18,H22,H24,H26,H32,H34 |

Thickness | 0.8-12mm |

width | 10~1200mm |

length | 1000-10000mm |

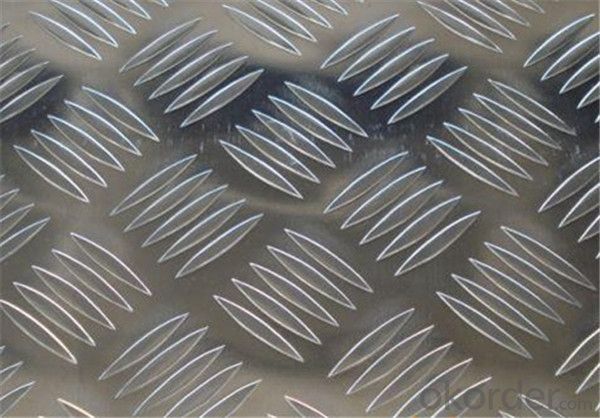

Decorative design | Five bars, classic stucco(orange peel), variation stucco, semi-circle, diamond ,three bars, two bars ,compass etc |

Coating | PE and PVDF |

Application/use | Widely used in refrigeratory house ,floor, freight car, ship, compartment lamp, construction platform ,air conditioner ,lift for skid-resistance etc |

Quality certificate | ISO 9001-2008 ,SGS |

Technical standard | GB/T 3880 |

MOQ | 3-5 tons, negotiable |

Payment terms | T/T or L/C |

Delivery | About 20~25 days after receipt of deposit |

Package | Export standard package |

Kindly remind | Our machine can cut any size according to your requirement |

FAQ

1, Question: What your mini order?

Answer: Our mini oder can be 5 tons. It just likes shopping. Good for you!

2, Question: If i buy larger quantity, is there any discount or good payment terms?

Answer: Take it easy,budy, we have the good financial policy like the credit period, it can enlarge your business.

3, Question: How can I get the best price?

Answer: For more than 20 years experience, we can keep the low the price in this aluminium market. Our products has been widely exported to U.A,.E, India, Unkraine, Europe and South American.We have the faith to keep the low price.

Photos

- Q: How do you join aluminum sheets together?

- There are several methods to join aluminum sheets together, depending on the specific application and desired strength of the joint. Here are some common techniques: 1. Welding: Aluminum can be welded using various methods such as gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), or even laser welding. These processes involve melting the aluminum at the joint and adding a filler material to create a strong bond. Welding offers excellent strength and durability but requires skill and appropriate equipment. 2. Riveting: Rivets can be used to fasten aluminum sheets together. This method involves drilling holes through the sheets and using a rivet gun to insert and deform a rivet, creating a secure joint. Riveting is relatively simple and quick, but it may not provide the same strength as welding. 3. Adhesive bonding: Industrial adhesive bonding is a popular method to join aluminum sheets. Specialized adhesives formulated for aluminum bonding are applied to the surfaces, which then cure and form a strong bond. Adhesive bonding is advantageous as it distributes stress evenly and can join dissimilar materials. However, it may not be suitable for high-temperature or high-stress applications. 4. Mechanical fasteners: Screws, bolts, or nuts can be used to fasten aluminum sheets together. This method involves drilling holes and using fasteners to secure the sheets. Mechanical fasteners provide good strength and allow for disassembly if needed. However, they may require additional maintenance and can cause stress concentrations around the holes. 5. Clinching: Clinching is a cold joining method where aluminum sheets are pressed together using a punch and die. The process deforms the materials and creates a mechanical interlock, forming a strong joint. Clinching is a quick and cost-effective method, but it may not be suitable for thin or highly rigid sheets. Ultimately, the choice of joining method depends on factors such as the required strength, aesthetics, cost, and ease of fabrication. It is recommended to consult with a qualified professional or follow specific guidelines to ensure a successful and reliable joint.

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: What are the different fabrication methods used for aluminum sheets?

- Aluminum sheets undergo various fabrication methods, each presenting its own advantages and applications. Rolling, extrusion, casting, and stamping are among the most commonly employed techniques. Rolling, the most prevalent method, entails passing the aluminum through a series of rollers to reduce thickness and form a flat sheet. This approach allows for precise control over sheet thickness and shape, rendering it suitable for an array of applications, from packaging to building materials. Another well-received method is extrusion, where heated aluminum is pushed through a die to create a specific shape or profile. This technique is commonly employed to manufacture intricate shapes like tubes, rods, and channels. Extruded aluminum sheets exhibit high strength and durability, making them appropriate for structural applications in construction and automotive industries. Casting involves pouring molten aluminum into a mold, allowing it to solidify. This method is frequently used for producing intricate shapes that are challenging to achieve through other means. Cast aluminum sheets can boast unique textures and designs, making them popular for decorative purposes. Stamping utilizes a press to shape the aluminum sheet by exerting pressure and forming it into the desired shape. This technique is commonly utilized for creating precise, small parts such as brackets, connectors, and electrical components. Stamped aluminum sheets offer exceptional dimensional accuracy and can be produced in large quantities at a relatively low cost. Additionally, other fabrication techniques such as welding, bending, and laser cutting can be employed to further process aluminum sheets and craft custom shapes and designs. In conclusion, the choice of fabrication method for aluminum sheets relies on the desired application, required properties, and complexity of the desired shape. Each method possesses unique advantages and capabilities, enabling a broad range of possibilities in aluminum sheet fabrication.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and in bulk. While it may depend on the specific supplier or retailer, many offer aluminum sheets in various sizes and quantities to meet the diverse needs of customers. Whether you require a few sheets for a small project or a larger quantity for industrial purposes, it is worth exploring different suppliers to find the option that best suits your requirements.

- Q: Are the aluminum sheets suitable for manufacturing sporting equipment?

- Yes, aluminum sheets are suitable for manufacturing sporting equipment. Aluminum is a lightweight and durable material that can be easily molded and shaped into various sporting equipment such as tennis rackets, baseball bats, and golf clubs. It offers excellent strength-to-weight ratio, corrosion resistance, and allows for better performance and maneuverability in sports activities.

- Q: Are aluminum sheets suitable for architectural canopies?

- Yes, aluminum sheets are suitable for architectural canopies. Aluminum is a lightweight and durable material that offers excellent weather resistance and structural integrity, making it an ideal choice for canopies. It can be easily fabricated into various shapes and sizes, allowing for versatile and aesthetically pleasing designs. Additionally, aluminum can be coated or anodized to enhance its appearance and protect it from corrosion, further enhancing its suitability for architectural canopies.

- Q: what is the behaviour of Al2O3= aluminium oxide and SiO2= silicon dioxide when heated from room temperature to 1000 degree celcius?

- Aluminium oxide is a metal oxide and here shows it's basic properties. Silicon dioxide is a non metal oxide, so acidic Acid + base ---- salt so aluminium silicate is formed

- Q: What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets may differ due to several factors, including the aluminum alloy, the tempering process, and the sheet thickness. Typically, aluminum sheets exhibit a yield strength that falls within the range of 10,000 psi (69 MPa) to 45,000 psi (310 MPa). Nonetheless, it is crucial to acknowledge that these values are only estimates and can fluctuate depending on the precise grade and temper of the aluminum in question.

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles when constructing exterior cladding.

- <p>For bonding aluminum profiles in exterior cladding, several types of adhesives are commonly used. These include: 1. Structural adhesives, which provide strong and durable bonds suitable for load-bearing applications. 2. Silicone sealants, known for their flexibility and resistance to weathering, making them ideal for sealing gaps and joints. 3. Acrylic adhesives, which offer good adhesion and flexibility, and are often used for bonding aluminum to other materials. 4. Epoxy adhesives, known for their high strength and resistance to chemicals, making them suitable for demanding environments. 5. Polyurethane adhesives, which provide strong bonds and excellent resistance to moisture and temperature changes. The choice of adhesive depends on factors such as the specific application, environmental conditions, and required performance characteristics.</p>

Send your message to us

032 Aluminum Diamond Plate Sheets - Embossed Aluminum Sheet Five Bars Aluminum Sheet 0.1~5mm 3 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords