Aluminium Corrugated Sheet for Roofing with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

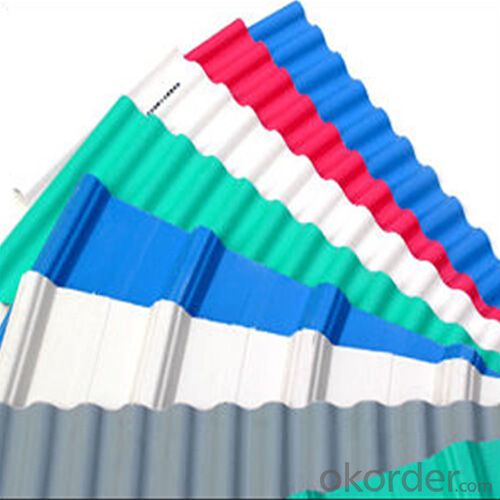

1.Structure of Aluminium Corrugated Sheet for Roofing Description:

Aluminium Corrugated Sheet for Roofing is produced advanced technology. Selecting qualified materials and the products have been tested and approved by National Test and Inspection Center for Building Materials, and also tested and approved by European and American Quality Testing System, in accordance with GB/T17748-1999 standards. As one of the international famous brands, IDEABOND developed and researched new products on the basis of aluminum-plastic plate, including fireproof aluminum-plastic composite plate, titanium zinc composite plate, titanium compound plate and stainless steel composite plate etc.

2.Main Features of Aluminium Corrugated Sheet for Roofing :

Corrosion resistance

Electrical conductivity

Fabricability

Temperature conductivity

3. Aluminium Corrugated Sheet for Roofing Images:

4. Aluminium Corrugated Sheet for Roofing Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- Aluminum is a good choice if you plan on using it to grind more than just coffee. Plastic tends to soak up flavors due to oils in coffee, herbs and spices. So if you plan on multitasking metal is the way to go.

- Q: What are the weight and density of aluminum sheets?

- The weight of aluminum sheets can vary depending on their thickness and size. However, the density of aluminum is approximately 2.7 grams per cubic centimeter.

- Q: Can aluminum sheets be used for heat shields in appliances?

- Yes, aluminum sheets can be used as heat shields in appliances. Aluminum is a good conductor of heat, making it an effective material for dissipating and reflecting heat away from sensitive components in appliances. Additionally, aluminum is lightweight, durable, and has good corrosion resistance, making it a suitable choice for heat shield applications in various appliances.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum size of aluminum sheets can differ based on the manufacturer and specific use. Nonetheless, as a rule, aluminum sheets typically have a standard maximum size of 4 feet by 12 feet (48 inches by 144 inches). This size is widely employed across industries like construction, automotive, and aerospace. Nevertheless, it is crucial to acknowledge that certain suppliers may offer larger sizes upon request, albeit with additional expenses and factors to consider.

- Q: Can aluminum sheets be used for decorative purposes?

- Certainly, decorative purposes can indeed be served by aluminum sheets. Aluminum, as a versatile and lightweight material, lends itself easily to manipulation into various shapes, sizes, and designs. It can be painted, coated, or anodized with a multitude of colors to suit any aesthetic preference. In the realm of decoration, aluminum sheets prove useful as panels, signage, wall cladding, ceiling tiles, and even in furniture design. Moreover, aluminum's resistance to corrosion renders it a durable choice for both indoor and outdoor applications. Furthermore, its reflective surface adds a sleek and modern touch to any space. In summary, aluminum sheets offer a vast array of possibilities for incorporating decorative elements into any project.

- Q: What is the thermal expansion coefficient of aluminum sheets?

- The thermal expansion coefficient for aluminum sheets measures around 23.1 x 10^-6 per degree Celsius, resulting in a length expansion of 23.1 parts per million for every one-degree Celsius temperature rise. Nevertheless, it's worth noting that this coefficient might slightly differ depending on the exact alloy and manufacturing technique employed in the production of the aluminum sheet.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Certain applications can consider aluminum sheets as an alternative to glass. Aluminum sheets provide various benefits over glass, making them suitable for specific scenarios. To begin with, aluminum sheets possess lightweight and durable characteristics, making them an excellent choice for industries like aerospace or automotive, where weight is a concern. Conversely, glass is relatively heavy and brittle, limiting its usage in certain environments. Moreover, aluminum sheets exhibit exceptional resistance to corrosion, making them a suitable option for marine or coastal applications, where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also possess a high strength-to-weight ratio, enabling greater design flexibility and structural integrity compared to glass. Furthermore, aluminum sheets offer superior thermal insulation properties in comparison to glass. They provide improved resistance to heat transfer, which is advantageous in applications where temperature control is crucial, like the construction industry. Additionally, aluminum sheets can be more cost-effective than glass in specific applications. The production and installation costs of aluminum sheets are often lower than glass, making them a more economical choice for large-scale projects. However, it is important to acknowledge that glass retains its own unique properties and advantages, such as transparency and optical clarity. Glass also has better resistance to scratches and chemical corrosion when compared to aluminum sheets. In conclusion, while aluminum sheets can serve as a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the final decision between the two materials depends on the specific requirements and limitations of the application at hand.

- Q: This question asks for criteria or factors to consider when selecting a high-quality aluminum sheet.

- <p>To choose a quality aluminum sheet, consider the following factors: 1) Thickness and weight, which should meet your specific project requirements. 2) Surface finish, ensuring it's smooth and free from defects. 3) Purity and alloy type, as different alloys have different properties. 4) Certifications, ensuring the sheet meets industry standards. 5) Supplier reputation and customer reviews for reliability. 6) Price, ensuring it's reasonable for the quality. 7) Conductivity and strength, depending on your application. 8) Corrosion resistance, important for longevity. Always inspect the sheet for any visible defects and ensure it's from a reputable supplier.</p>

- Q: What are the benefits of using aluminum sheets?

- There are several benefits of using aluminum sheets. Firstly, aluminum sheets are lightweight compared to other metals, making them easier to handle and transport. Secondly, aluminum is highly resistant to corrosion, making it suitable for outdoor applications and in humid environments. Additionally, aluminum sheets are versatile and can be easily formed into various shapes and sizes, making them suitable for a wide range of applications. Moreover, aluminum is a good conductor of heat and electricity, making it ideal for use in electrical and thermal conductivity applications. Lastly, aluminum sheets are recyclable, making them a sustainable choice and reducing environmental impact.

- Q: This question asks for various methods through which aluminum sheets can be recycled and repurposed.

- <p>Aluminum sheets can be recycled and reused in several ways: 1. Melting and Reformation: The most common method is to melt down the aluminum and reform it into new products. 2. Mechanical Recycling: This involves shredding and compacting the aluminum sheets to be used as raw material in new products. 3. Energy Recovery: The heat generated from burning aluminum can be used to produce energy. 4. Alloying: Aluminum can be combined with other metals to create new alloys with different properties. 5. Reuse in Construction: Aluminum sheets can be reused in construction projects, such as facades or roofing. 6. Manufacturing: They can be used in manufacturing processes to create new aluminum products like cans, foils, and automotive parts. Proper recycling of aluminum reduces environmental impact and conserves resources.</p>

Send your message to us

Aluminium Corrugated Sheet for Roofing with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords