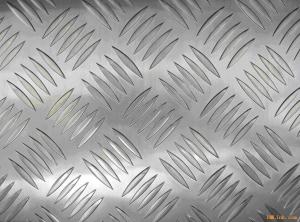

Reflective Five-Bar Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Five-Bar Aluminum Sheets Description

Five-Bar Aluminum Sheets has great ductility, heat conductivity, anti-corrosion and moisture resistance properties which are very useful in the field of construction.

Five-Bar Aluminum Sheets is widely used for decorative purpose in construction, packing and appiance. It is also very commonly used for anti-slippery purpose in vehicles and public places.

2.Main Features of Five-Bar Aluminum Sheets

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Five-Bar Aluminum Sheets Images

4.AlumFive-Bar Aluminum Sheets Specification

Alloy | AA1xxx, AA3xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Five-Bar Aluminum Sheets

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Five-Bar Aluminum Sheets products.

B.When will you deliver the products?

The Five-Bar Aluminum Sheets will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can be used for manufacturing furniture. Aluminum is a lightweight and durable material that can be easily shaped and formed into various furniture designs. It is also corrosion-resistant, making it suitable for both indoor and outdoor furniture applications.

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- 1) okorder /

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight, durable, and corrosion-resistant properties. It is also easy to work with and can be easily shaped and formed to fit various duct designs.

- Q: Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- When the air injection in silicone sealant generally refer to the site to complete the injection work, poor working conditions. The workers stood above the tripod glue injection, the uniformity of rubber injection is not easy to master, which is easy to glue in air. After sizing glue scraping the surface pressure, trimming smooth, adhesive seam inside the pad bar are mostly made of polyethylene foam obturator rods in the air inside the glue is not easy to overflow, glue dressing compressed air, will produce tension long outward, sealant seam is generally wide, small thickness, arch high displacement ability of weather resistant glue, hardness is low, no pre curing glue is very soft, compressed air pressure to hold long glue slowly bubbling. This phenomenon is more likely to occur on the application of weather resistant adhesive capable of lifting the arch + 25% or more adhesive displacement. Conversely, some weather resistant adhesives that allow less displacement are higher in hardness and thicker before the gel is solidified.

- Q: Are the aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it an ideal choice for outdoor use. Additionally, aluminum sheets are lightweight, durable, and have excellent thermal and electrical conductivity, further enhancing their suitability for various outdoor applications.

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Yes, aluminum sheets can be used for manufacturing door frames. Aluminum is a versatile material that is widely used in construction due to its strength, durability, and lightweight properties. It can be easily shaped, bent, and welded to create door frames of various sizes and designs. Additionally, aluminum is highly resistant to corrosion, making it suitable for both interior and exterior applications. Overall, using aluminum sheets for manufacturing door frames is a practical and popular choice in the construction industry.

Send your message to us

Reflective Five-Bar Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords