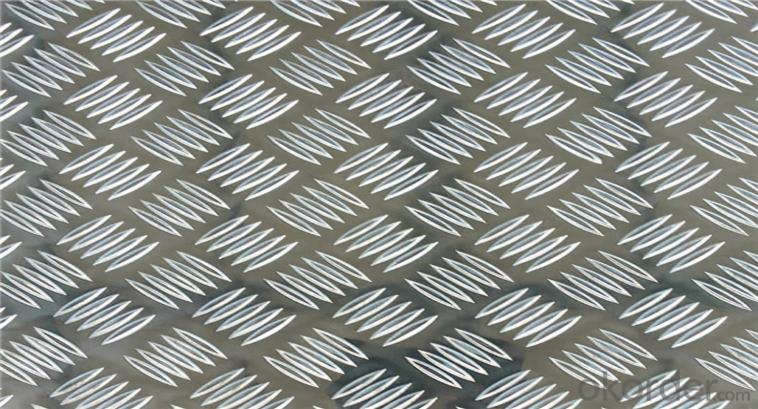

Five Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Five Bars Pattern Embossed Aluminum Sheet and Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Uage/Application of Five Bars Pattern Embossed Aluminum Sheet and Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Five Bars Pattern Embossed Aluminum Sheet and Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Five Bars Pattern Embossed Aluminum Sheet and Coil

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q: Are 101 aluminum sheets suitable for aircraft manufacturing?

- Yes, 101 aluminum sheets are suitable for aircraft manufacturing. 101 aluminum is a commonly used alloy in the aerospace industry due to its high strength-to-weight ratio, excellent corrosion resistance, and good formability. It is particularly well-suited for structural components and skin panels in aircraft manufacturing. Additionally, 101 aluminum sheets can be easily machined, welded, and joined, making them versatile and efficient for aircraft construction. Overall, 101 aluminum sheets meet the stringent requirements for aircraft manufacturing and are widely used in the industry.

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- In theory, yes, such as brazing.In fact, few people do that:Aluminum and steel systems do not form stable alloy remelting. Brazing is actually the use of third materials to link two original or dissimilar materials together. Unlike bonding, a stable alloy phase can be formed.

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- No, 101 aluminum sheets are not suitable for cryogenic applications. While aluminum is generally a good choice for low-temperature environments due to its low thermal conductivity and high strength-to-weight ratio, 101 aluminum is not specifically designed to withstand the extreme temperatures associated with cryogenic applications. For cryogenic applications, materials such as aluminum alloys (e.g., 5083 or 6061) or specialized cryogenic alloys like stainless steel or titanium are typically used, as they possess enhanced properties to handle the extreme cold temperatures without compromising their structural integrity. Therefore, it is recommended to use materials specifically designed for cryogenic applications to ensure optimal performance and safety.

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Domestic aluminum plating mainly in Jiangsu origin, the general material is relatively hard, and the surface is not imported, aluminum plate bright and clean, but the price is lower than the import. Imported aluminum plate mainly in the eastern Pohang, South Korea, Japan's three major steel. Pohang is the three major steel plant, the material is more flexible and tensile properties. The relative price is higher than domestic.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: What are the different packaging options available for aluminum sheets during transportation?

- There are several packaging options available for aluminum sheets during transportation. Some common methods include wrapping the sheets in protective film or paper, using wooden crates or pallets to stack and secure the sheets, and using cardboard or plastic edge protectors to prevent damage. Additionally, aluminum sheets can also be packaged in custom-cut foam or bubble wrap for added cushioning and protection during transit.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets are significantly lighter than steel sheets, as aluminum has a lower density compared to steel.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets can vary depending on the manufacturer and specific application. However, in general, the standard maximum sheet size for aluminum sheets is typically 4 feet by 12 feet (48 inches by 144 inches). This size is commonly used in various industries such as construction, automotive, and aerospace. It is important to note that larger sizes may be available upon request from certain suppliers, but these may come with additional costs and considerations.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Aerospace fuel tanks can indeed utilize aluminum sheets. In the aerospace industry, aluminum is widely employed because of its lightweight yet robust characteristics. Its strength-to-weight ratio is commendable, rendering it an ideal choice for fuel tanks that must endure the forces of flight while minimizing the aircraft's overall weight. Moreover, aluminum's resistance to corrosion is pivotal for aerospace fuel tanks, considering their exposure to diverse fuels and environmental conditions. Furthermore, aluminum's ease of fabrication and widespread availability make it a cost-efficient option for aerospace applications. In summary, aluminum sheets are a fitting material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several different methods of surface passivation for aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include anodizing, chromate conversion coating, and organic coating. 1. Anodizing: Anodizing is a widely used method that involves creating a thick protective oxide layer on the surface of the aluminum sheet. This is achieved by immersing the sheet in an electrolyte solution and passing a current through it. Anodizing provides excellent corrosion resistance, improves the surface hardness, and allows for various color options through dyeing. It is commonly used in architectural and decorative applications. 2. Chromate conversion coating: Chromate conversion coating, also known as chemical conversion coating or chromating, involves treating the aluminum surface with a solution containing chromate compounds. This method provides a thin, protective layer that improves corrosion resistance and enhances paint adhesion. It is widely used in aerospace, automotive, and electronics industries. 3. Organic coating: Organic coating refers to the application of a protective layer of organic material, such as paint or powder coating, onto the aluminum surface. This method provides exceptional corrosion resistance and can also offer aesthetic options. Organic coating is commonly used in industries where the aluminum sheets are exposed to harsh environments or require specific colors or finishes. 4. Plasma electrolytic oxidation (PEO): PEO is a relatively newer method that involves immersing the aluminum sheet in an electrolyte solution and passing high-voltage current through it. This process leads to the formation of a ceramic-like oxide layer on the surface, which enhances corrosion resistance, hardness, and wear resistance. PEO is commonly used in applications requiring high-performance coatings, such as aerospace and automotive industries. 5. Passivation with acids or chemicals: Passivation using acids or chemicals involves treating the aluminum surface with a solution that removes impurities and forms a protective layer. This method helps in reducing the reactivity of the surface and enhances corrosion resistance. It is commonly used in industrial applications where aluminum sheets are exposed to harsh chemicals or environments. Overall, the choice of surface passivation method for aluminum sheets depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hardness, and environmental factors. It is important to consider factors such as cost, durability, and the desired performance characteristics when selecting the appropriate method.

Send your message to us

Five Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords