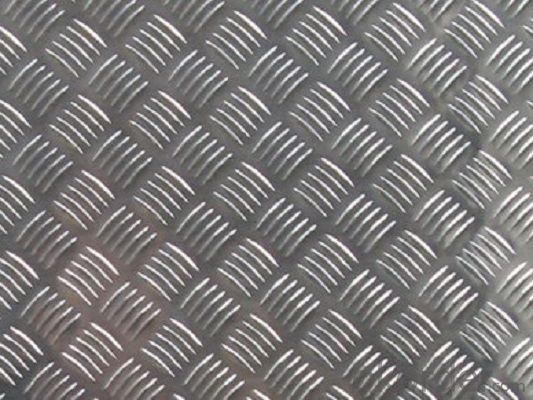

Wholesale 5 Bars Embossed Aluminum Sheets with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Aluminium Sheet

5 bars embossed aluminum sheets :

1,Alloy:1xxx,3xxx,5xxx

2,Thickness:1.0-10mm

3.Width:1000-1700mm

4.Temper:O-H112

width and length:to cut as your requirement thickness:0.15-0.3m Tensile Strength:130~150MPa .Yield Strength:130-145.Elongation:≥2%,Earing Rate:≤2%.There are no stop marks or pinch marks on the surface of aluminum sheets.

There are no water stains or blisters on the surface.

The Main Features of Aluminium Sheet:

High quality with competive prices.

Wide product range of choice.

We are specific manufacture and control.

The Images of Aluminium Sheet:

FAQ:

1. Minimum Order Quantity? MOQ is 25 tons, your quantity is ok, the aluminium foil sample is available. |

2. What kind of terms of payment? T/T, L/C,D/A,D/P,Western Union are available. |

3. What grams of the product can you offer? Our products can be customized according to your requirment |

4.Can you do Customization & Reproduction if I provide a photo? Yes, we do Customization & Reproduction service, please check the details and sample above. You need to send the pictures to our email, tell us the specification you want, then we will quote you exact price. We will take photos for you check. |

5. Does the packaging safe and arrive in good conditions? Yes, Safe Packing guarrantee, all the products will arrive your door under good conditions. We response to problem of shipping if there unfortunately is. |

6. How long does it usually take to deliver the product? We'll make the shipment to you immediately. It will take about 18 to 40 days arrive worldwide. Accurate delivery time depends on the specific quantity |

7.Is drop shipping abailable? Yes, it is, we can send to worldwide. |

- Q: What kind of material is wood grain aluminum sheet?

- Wood grain aluminum plate itself is the main aluminum alloy,The surface of that wood grain should be paint or ink

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a highly durable and corrosion-resistant material, making it ideal for outdoor applications. It is lightweight, yet strong enough to withstand harsh weather conditions, such as rain, snow, and UV radiation. Additionally, aluminum sheets can be coated or painted to further enhance their resistance to corrosion and provide added protection against the elements. This makes them a popular choice for outdoor structures, signage, roofing, and other exterior applications where durability and longevity are essential.

- Q: Are aluminum sheets easy to clean and maintain?

- Yes, aluminum sheets are relatively easy to clean and maintain. Aluminum has a natural resistance to corrosion and rust, which makes it a low-maintenance material. To clean aluminum sheets, you can use mild soap and water, along with a soft cloth or sponge. Avoid using abrasive cleaners or scrub brushes, as they can scratch the surface. Additionally, it is important to dry the aluminum sheets thoroughly after cleaning to prevent water spots or stains. Regular maintenance involves wiping away any spills or stains as soon as possible and periodically applying a protective coating to enhance its longevity. Overall, aluminum sheets are a convenient choice for those seeking a material that is easy to clean and maintain.

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a versatile material that offers several advantages for facade applications. It is lightweight, durable, and corrosion-resistant, making it suitable for various weather conditions. Aluminum sheets can be easily fabricated and installed, offering flexibility in design and allowing for intricate and complex facades. Additionally, aluminum can be finished in a variety of ways, including powder coating, anodizing, or painting, to enhance its appearance and provide the desired aesthetic appeal. Overall, the use of aluminum sheets for architectural facades provides architects and designers with a wide range of options to create visually appealing and long-lasting building exteriors.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: Does Aluminum Foil really work to help beat the summer heat?I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just mentioned it's usually in the high 60s or low 70s during the spring and summer, perfect.Will Aluminum Foil work or can someone else suggest anything else?!PLEASE note that I'm just putting aluminum foil on my bedroom window which just faces some other apartment complex and I am not concerned with the aesthetics. I might consider putting something up (but just not sure what) on the living room window other than aluminum foil since everyone can see that window.

- If it was me id put window tint that has a reflective(aluminum coating) facing outward. It works well and is more appealing,also your apt mgr may not approve of the foil on the window.

- Q: And isn't aluminum extremely bad for ones health?

- it's okorder

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- determine which you do catch the Hydrogen gas in a balloon. combination Lye with water in a pitcher bottle (Coke liter bottle is huge). drop in Aluminum foil (do no longer give way) and cap off with a balloon. The balloon will fill with hydrogen. do away with the balloon, pinching the backside keeping the hydrogen; shop including Aluminum foil strips and place the balloon lower back over the precise till at last the balloon is of a sturdy length. Tie the balloon off, tape a fuse (some thing that burns slow) to the balloon, permit it bypass up interior the air. whilst the hearth its the balloon, it pops and the hydrogen + oxygen (interior the air) + spark reasons a small flash (hydrogen explosion). Do it at night for a extra advantageous view.

- Q: Do you use aluminum alloy boards or aluminum plates for outdoor billboards?

- Aluminum Alloy is a kind of nonferrous metal structural materials widely used in industry, has been widely used in aviation, aerospace, automotive, machinery manufacturing, shipbuilding and chemical industry. In recent years, with the rapid development of science and technology and industrial economic structure, increasing demand for Aluminum Alloy welding, the welding of aluminum the alloy also further widely used. Aluminum Alloy promoted the development of welding technology Aluminum Alloy, at the same time the development of welding technology and expand the application field of Aluminum Alloy, so Aluminum Alloy welding technology is becoming the research hotspot. A Aluminum Alloy: aluminum based alloy in general. The main alloying elements copper and silicon, magnesium, zinc and manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium and so on.

Send your message to us

Wholesale 5 Bars Embossed Aluminum Sheets with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords