Polyurethane Sandwich Panels in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

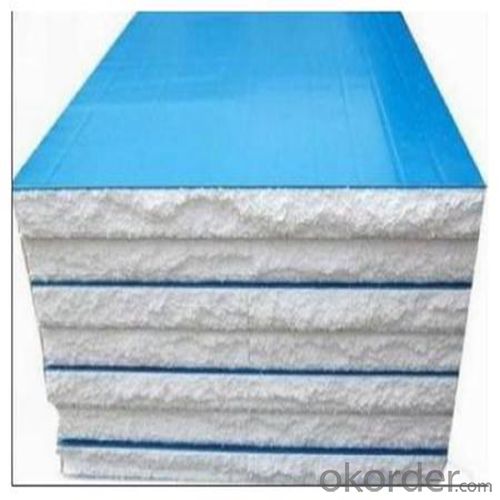

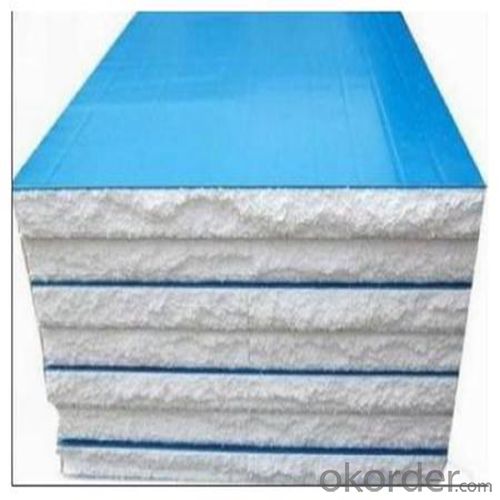

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How to guarantee the quality of the products?

4) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5) How long can we receive the product after purchase?

6) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How do steel sheets compare to other materials, such as aluminum or copper?

- Steel sheets have several advantages over other materials such as aluminum or copper. Steel is generally stronger and more durable, making it suitable for applications that require high strength and resistance to wear and tear. It is also more cost-effective and readily available, making it a popular choice in various industries. While aluminum and copper may offer better conductivity or corrosion resistance, steel sheets often provide a good balance of properties, making them a versatile and widely used material.

- Q: What are the safety precautions when handling steel sheets?

- When handling steel sheets, there are several safety precautions that should be followed to ensure the well-being of individuals and prevent accidents. These precautions include the following: 1. Personal Protective Equipment (PPE): It is essential to wear the appropriate PPE when handling steel sheets. This typically includes safety goggles or glasses, gloves, and steel-toed boots. PPE helps protect against potential injuries such as cuts, burns, and eye damage. 2. Proper Lifting Techniques: Steel sheets can be heavy and awkward to handle, so it is crucial to use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and use team lifting when necessary. Avoid any sudden or jerky movements while handling the sheets. 3. Secure Storage and Transport: When storing or transporting steel sheets, ensure that they are properly secured to prevent them from shifting or falling. Use appropriate equipment such as straps or chains to secure the sheets, and make sure they are evenly distributed to maintain balance. 4. Clear Work Area: Before handling steel sheets, ensure that the work area is clear of any obstacles or debris. This will help prevent tripping or slipping hazards and provide a clear path for moving the sheets. 5. Adequate Lighting: Proper lighting is essential to ensure good visibility when handling steel sheets. Insufficient lighting can increase the risk of accidents and injuries, so make sure the work area is well-lit to avoid any potential mishaps. 6. Training and Education: It is important for individuals handling steel sheets to receive proper training and education on safe handling procedures. This includes understanding the weight and dimensions of the sheets, as well as the correct techniques for lifting and moving them. 7. Awareness of Sharp Edges: Steel sheets often have sharp edges, which can cause cuts or lacerations. Always handle the sheets with caution and be aware of any sharp edges. If necessary, use protective guards or edge protectors to minimize the risk of injury. 8. Regular Maintenance and Inspection: Regularly inspect the steel sheets for any signs of damage, such as sharp edges, rust, or structural weaknesses. Replace or repair any damaged sheets to ensure safe handling. By following these safety precautions, individuals can minimize the risk of accidents and injuries when handling steel sheets. It is important to prioritize safety and take the necessary steps to protect oneself and others in the work environment.

- Q: What are the different packaging options for steel sheets?

- Some of the different packaging options for steel sheets include bundles, coils, pallets, and crates. Bundles are typically used for smaller sheets and consist of multiple sheets stacked together and secured with metal straps. Coils are used for larger sheets and are wound into a cylindrical shape. Pallets are commonly used for transportation and storage, where steel sheets are placed on top of a wooden or plastic pallet and secured with straps or stretch film. Crates are wooden or metal containers that provide additional protection for steel sheets during transportation and can be customized to fit specific sheet sizes and quantities.

- Q: How to choose welding method for welding different plate and thick steel plate?

- How to choose welding method for welding different plate and thick steel plate?:It depends on what process you use welding: manual arc welding, thick plate side should do thinner processing, become 12 thick, that is, a transition ramp, 15 degrees can be reached, two plates corresponding to the edge of the same thickness. V shaped groove, single side 30 meter, V shape 60 degrees. Clearance 2, blunt edge 1-2 can. Submerged arc welding, the plate can be assembled after thinning, without beveling.

- Q: Can steel sheets be painted or coated?

- Yes, steel sheets can be painted or coated. Painting or coating steel sheets can provide protection against corrosion, improve aesthetics, or serve specific functional purposes such as heat resistance or electrical conductivity.

- Q: Are steel sheets suitable for automotive chassis?

- Yes, steel sheets are suitable for automotive chassis. Steel is a popular choice for automotive chassis due to its strength, durability, and affordability. It provides excellent structural integrity and can withstand the various forces and stresses experienced by a vehicle during operation. Steel sheets also offer good resistance to impacts, vibrations, and corrosion, making them ideal for use in automotive chassis. Additionally, steel is a readily available material and can be easily formed, welded, and molded into different shapes and sizes, allowing for flexibility in design and manufacturing processes. Overall, steel sheets are a reliable and widely used material in the automotive industry for constructing chassis that meet the required safety, performance, and longevity standards.

- Q: What is the weight of a standard steel sheet?

- The weight of a standard steel sheet can vary depending on its dimensions and thickness. However, a commonly used gauge is 20, which has a weight of approximately 9.81 pounds per square foot.

- Q: Are the steel sheets suitable for HVAC ductwork?

- Yes, steel sheets are suitable for HVAC ductwork. Steel is a durable and strong material that can withstand the pressure and temperature changes typical in HVAC systems. It has excellent fire resistance properties and is resistant to corrosion, making it ideal for ductwork applications. Additionally, steel sheets can be easily fabricated and formed into various shapes and sizes to fit specific ductwork requirements. Therefore, steel sheets are a reliable and commonly used material in the construction of HVAC ductwork.

- Q: What are the different types of steel sheet finishes for marine applications?

- Marine applications commonly employ several different types of steel sheet finishes to enhance durability and corrosion resistance in the face of constant exposure to moisture, saltwater, and harsh weather conditions. 1. Hot-dip galvanized: Among the most frequently used finishes for marine applications is hot-dip galvanization. This process involves coating the steel sheet with a layer of zinc, effectively safeguarding against corrosion. The zinc layer acts as a sacrificial barrier, preventing rust formation in the underlying steel. 2. Stainless steel: Highly resistant to corrosion, stainless steel sheets find widespread use in marine applications. These sheets are composed of a steel, chromium, and nickel alloy, providing exceptional strength and corrosion resistance. Different grades of stainless steel sheets are available, with 316 stainless steel being the most commonly utilized in marine environments. 3. Powder coating: Powder coating is a favored finish for steel sheets in marine applications. The process involves electrostatically applying a layer of powdered polymer to the steel sheet, which is then cured under heat to form a robust and durable coating. Powder coating offers good corrosion resistance and can be tailored in terms of color and texture. 4. Epoxy coating: To ensure superior protection against corrosion in marine environments, steel sheets are frequently treated with epoxy coatings. These coatings boast chemical resistance and excellent adhesion to the steel surface. Epoxy coatings are also renowned for their high impact and abrasion resistance. 5. Organic coating: Organic coatings, such as polyurethane or acrylic coatings, are employed to shield steel sheets in marine applications. These coatings create a protective barrier against corrosion and are commonly utilized in offshore structures, ships, and other marine equipment. It is important to consider various factors, including specific environmental conditions, budget, and desired aesthetics, when selecting a steel sheet finish for marine applications. Consulting with a professional or referring to industry standards and recommendations can aid in determining the most suitable finish for a particular marine application.

- Q: What is the cost of a standard steel sheet?

- The cost of a standard steel sheet can vary depending on factors such as size, thickness, and quality. It is recommended to check with suppliers or retailers for current pricing information.

Send your message to us

Polyurethane Sandwich Panels in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords