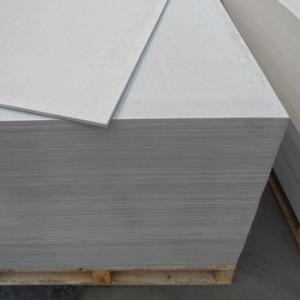

Non-asbestos Fireproof 12 mm Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non-asbestos Fireproof 12 mm Fiber Cement Board

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Non-asbestos Fireproof 12 mm Fiber Cement Board

Sound and Weather Resistant:

Karmeen fiber cement boards deliver optimal sound and weather insulation. Noise as well as changing weather conditions such as freeze / thaw, heat and water pose no threat to fiber cement board. The boards retain their shape at all times.

Low Maintenance:

The ability of the boards to resist mold and algae attacks is equally impressive. The result is a long-lived façade that saves you time and effort on inconvenient and costly repairs and repaints.

Non-combustible:

The boards are non-combustible, which is your guarantee for a safe building.

Easy Handling:

Karmeen fiber cement boards are flexible and easy to handle. They can be delivered cut to size, ready for installation. All this makes for lower construction costs, shorter construction times, and lower installed costs.

Board Edge:

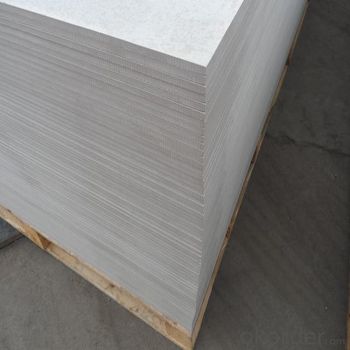

Packaging Details:

Fumigation wooden pallets+PE cover + corner protector

Non-asbestos Fireproof 12 mm Fiber Cement Board

- Q: Is it possible to use a cement board with a small double intermediate compartment?

- Yes, the first board for the two-way board, plate thickness for the short span of 1/40 ~ 50, you can use 90 ~ 112.5mm thick

- Q: pre-tiling bathroom floor

- Screw or nail it right now! The idea of the thinset , so when it is secured is to fill any and all voids .. If you wait to long the thinset may have to be scraped up and you start anew. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Wood fiber cement board | US rock cement board use

- Wood fiber cement board is a kind of natural wood and natural cement, the use of high-pressure slurry technology integrated sheet. With excellent characteristics of wood and cement.

- Q: also how much is luber per board foot cost.

- One bag of Cement is 195 pesos. ($4). Cocoa Lumber is P50 per board foot.

- Q: I've put up my cement board walls now not sure what 2 use on it as a thin coat? I am not going 2 put tile on just want a textured cement look. Also is there a metalic type paint I can use on cement? I'm looking for options in my new shower area. There is a wax or plastic also that looks like it was a type of tile adhesive that I don't know how to get off before I stain or paint the concrete. Any suggestions on how to get it off? Can I use spray paint on the concrete in a shower area? Thank you

- If water is going to be drenching it constantly it will peel.

- Q: Cement fiber board now market price?

- The thickness of different prices, specifications for the 1200x2400 need to point to my information contact me

- Q: I need to fix a loom board cause one of the pegs broke we don't have superglue but we have vinyl cement can I use that?

- No. Honey has got it right. Wood glue (yellow) is the stuff to use. To do it properly, the broken peg needs to be drilled out and a new peg (dowel) needs to be put in. If a loom board is what I think it is, it is under stress (which is why it broke) and that joint needs to be as strong as possible.

- Q: What besides cement board can i use to set tile on?

- Hi Kaitlin, here's a link to a product called Denshield. I like it very well as it's much easier to work with than cement board. I think you could find this product locally.

- Q: I have a friend who owns a house who believes it was built in 1968. The basement is in immaculate condition-- completely dry. The walls are poured cement and you can see where the forms were taken off the wall after it was poured. My question -- did they pour walls back in 1968 or was cinder block the building material used? I think the house was renovated within the last 15 years. My friend and I are baffled. Thanks!

- Glue is not going to work for you... You should put a vapour barrier down first (under the bottom plate). This can be 'Sill gasket' (which is foam on a roll about 6 wide...) or tar paper or even just 6 mil plastic. This will prevent the bottom plate from 'drawing moisture' through the concrete. Usually a basement floor is only a few inches (at best) deep of concrete and then there's stone and dirt below that. Moisture will pass through concrete over time and if the conditions are right, mould will grow in a few years... in your bottom plate and lower studs. I always use tar paper, set the position of the bottom plate, drill with a concrete bit and then use a hammer-in type anchor... These anchors work like a pin driven down through a hollow shaft that expands. You drill right through the bottom plate and the floor, set one of these in the top of the board and whack it with a hammer to pound the pin into the hollow shaft that you stuck in the hole in the wood... works awesome, easier and cheaper than tapcons and really strong at one every 16 or so (between the vertical studs). Home Depot has them by the box in different sizes... Good Luck!

- Q: how do i install stone veneer over cement board?

- the instructions you get with whatever stone you decide on will explain it in detail...usually mesh with a base coat and then a bonding layer and then the pointing if it is a mortared joint...

Send your message to us

Non-asbestos Fireproof 12 mm Fiber Cement Board

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords