Non-asbestos Waterproof Fireproof Fiber Cement Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Fiber cement board is a new architechural and industrial board with cement, quartz, matural and selected minerals as main materials. The board was made through high temperature and high precessure maintenance and other special treatments. It is the first choice for lasting building materials in some developed countries as well as being increasingly applied in more countries.

Specifications

1220x2440x4-20mm, Max width: 1220mm, Max length: 3000mm

Other optional specification available

Optional sanding finishing on the surface

Advantages

1. 100% Asbestos Free

2. Fire Resistance

3. Earthquake Resistance

4. High Strength and Good Stability

5. Inorganic Material and Anti Fungus

6. Good Heat and Sound Insulation

7. Durability and Long Service Life

Typical Applications

Commercial mansion, Industrial building, Hotel, Hospital, Theater, Station, Factory, Warehouse, etc.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

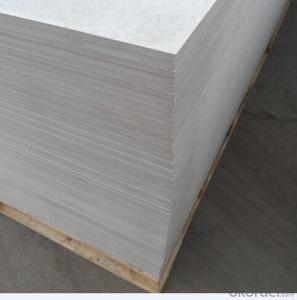

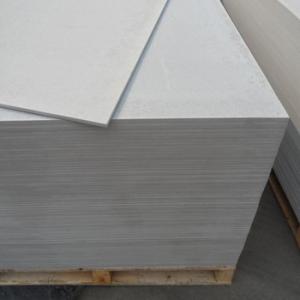

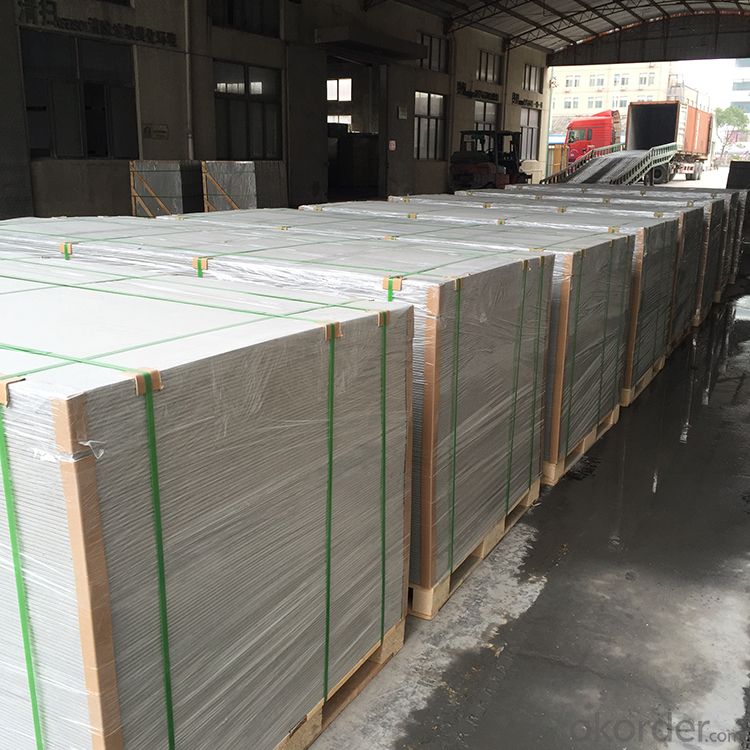

Picture

- Q: okay so im making a notebook collage n i was wondering if i can use rubber cement...oh and does it dry clear because i added some now and it's kinda dark colored and i don't want people to see the stains.. i dont have an eraser or anything like that!

- I used it many times to temporarily glue photography artwork to the matting board. The good thing about it -- it is removable when dry. Just scrub it lightly with a paper towel or even with your fingers. I buy my rubber cement in art supply stores, it is not dark colored at all and they also sell a convenient big rubber eraser for it. Beware: it is not to create a permanent bond; the photos will fall off in time.

- Q: Does backerboard need to be installed for new kitchen tile with cement floor?

- No you do not need to put down backer board over cement(concrete) floor. A concrete floor is the perfect substrate for tile.

- Q: i would also like to know what products might help me. Thanks :) Oh, and the type of board i got is called hardi-bord... i didnt know if that might help.

- Cement Board Sealer

- Q: What is the difference between cement board decoration and gypsum board?

- Gypsum board is gypsum as the main material, adding fiber, adhesive, modifier, by mixing to suppress, dry from. With the fire, noise, heat, light, high strength, low shrinkage characteristics, because the gypsum board is relatively easy to putty, generally used to decorate the paint to paint latex paint, but poor water resistance, not suitable for use in humid environments The

- Q: i am having alotta trouble on the cement like i cant get both feet back on the board.any tips?

- One problem could be that you arent as confident as you are in the grass because you think that you might hurt yourself.

- Q: nothing to add...

- Sure. It may react a little differently because of the moisture absorbing properties of the cement board. Try some tests and experiment with moistening the cement board before applying the texture.

- Q: Performance of fiber cement pressure plate

- Sound insulation: high density, good sound insulation; low thermal conductivity, thermal insulation performance.

- Q: how to make cement backer board for bathroom wall tiling?

- the other people answering are inexperienced. forget them. leave the drywall that is already there. install the tile with an upgraded mortar like flexbond ($30 a bag) as opposed to regular mortar at $15 a bag. the tile will be going nowhere, vent fan or no vent fan. put your tiles pretty tight together to avoid the use of alot of grout. water gets in through the grout lines which makes the tiles come loose. seal the grout with a can of grout sealer every so often so moisture doesnt get behind the tiles.

- Q: What does the glass wire add to the cement?

- The effect of adding glass cement can not only improve the alkali resistance of glass fiber, but also reduce the erosion of glass fiber. It is an early strength, high strength, low alkali, impermeability, corrosion resistance, freeze-thaw resistance, Micro-expansion and contraction, negative temperature construction, coloring and other properties in one, can inhibit the alkali - aggregate reaction of the 21st century new cement. After testing and calculation, the durability of alkali glass fiber in the composite of Portland cement is one year, and the composite alkali-resistant fiberglass fiber is 17 years. The glass fiber cement is 52 years, and the composite alkali-resistant glass fiber is 155 years.

- Q: installed the most powerful exhaust fan that is made and my newly painted hardi backer walls are sweating when take a shower or bath with the fan running- what can I do?

- is it the outside wall.it may need to be insulated.

Send your message to us

Non-asbestos Waterproof Fireproof Fiber Cement Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords