Non-Asbestos Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1.Easy to work

2.Heat insulation

3.Sound insulation and fire resistance

4.Thickness: 4 - 15mm

Fiber Cement Board

Product Advantages:

100% non-asbestos Fiber Cement Board

100% non-asbestos Fiber Cement Board presents the art of Germany know-how as a high quality building materials.All boards are autoclaved to become stable product.fiber cement board does net contain any of asbestos fiber, however, it has strong bending strength like those with system.It has low water absorption rate and high impact resistant ability.These good advantages make it suitable for any purposes of applications.

high density fiber cement board is made by wood lengthy fiber,concrete,silicon sand and etc.Made under the high pressure water vapor process,therefore,it performs well in humidity durability,force resistance ,fiber proofing. fiber cement board is suitable in indoor partition, ceiling and decoration purpose.

Main Product Features:

1) 100% asbestos free

2) Non-combustible: PSB, GB8624, CLASS A

3) Moisture resistant

4) Excellent impact resistance

5) Excellent sound insulation

6) High dimensional stability

7) Good surface finish

8) Easy to work, fix and decorate.

Elements:

Wood fiber: 8%+Sio2:35-45%+Ca materials: 15-30%+ Cement: 10-20%+Other Accessories: 5%.

Specifications:

1) Thickness: 4 - 15mm

2) Max. width: 915mm,1830mm,1,220mm(Others could be also available according to your requirment)

3) Max. length: 2,440mm.4,880mm(Others should be also available according to your requirment)

4) Edges: square / beveled / tapped.

Applications:

1) Internal and External partition wall applications in commercial, large office building and public ceiling ,curtain wall and so on.

2) Substrate board, applications in wet environment, such as kitchens and bathrooms ;

3) Substrate for flooring

4) Eave lining

5) Filling slurry wall

6) Special environments such as ward, laboratory and asepsis room.

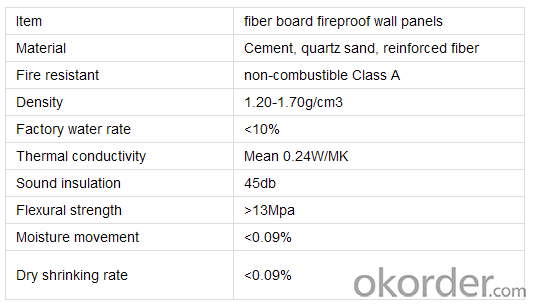

Product Specifications:

Images:

- Q: How to brush latex paint on the cement board

- Patch: the general light walls and insulation walls and other non-load-bearing walls are required to patch, try to choose a better texture of the wall cloth and white latex, if the conditions can be used grid cloth, the relative crack effect will be better a little. Putty: scraping 2-3 times putty, the use of fine fineness and texture of the hard putty better, you can also add some white latex in the putty, you can improve the hardness of putty. Polished: try to use a thin sandpaper, the general texture of the more soft putty (such as 821) with 400-500 sandpaper, hard texture (such as wall lining, easy to draw flat) with 360-400 is better, if the sandpaper Too thick words will leave a deep sand marks, paint is covered. Polished must be thoroughly cleaned the wall again, so as not to dust too much, affecting the adhesion of paint. Unevenness of not more than 3 mm

- Q: Will Titebond II (weatherproof) work? I have a 1928 home and am trying to duplicate one of the original exterior window sills to go on a new window. I need to glue a couple of 5/4 pieces together to get the right thickness and I want it to last. The originals have redwood but it's old growth I believe and more stable than what I can find now in redwood or DF. Correct me if I'm wrong there. Plus I have only two attaching points to work with on either side of the window so I chose the fiber cement product for it's stability. Nothing on James Hardie's site says what can be used to glue it with though.ThanksThanksChris

- I would use gorilla glue which is 100 percent waterproof. or you could use polyurethane caulk which is very tough.

- Q: Can veneer cement board be on the floor?

- VIVA wood cement board is environmentally friendly green building materials, from cement as a cross-linking agent, wood as a fiber reinforced material, adding part of the additives made of pressed sheet, mainly by the crushed wood chips and Portland cement glued together, the color Clean, double smooth and smooth. The product combines the strength of wood, ease of processing and cement durable characteristics. Wood fiber cement board in the 40's began to be widely used in Europe, has now become a wide range of international application of building materials. It is versatile, excellent performance, with corrosion resistance, heat resistance, resistance to corrosion, easy processing, and cement, lime, gypsum with good, green and other advantages.

- Q: Anyone that can supply UAE - Middle East, preferrably from the UK, Europe, Australia and New Zealand.

- Some years back I kept a Praying Mantis as a pet, and they only eat live food! Consequently, I acquired the skill of GENTLY capturing live flies in flight, or off any surface, so that I could feed my Mantis uninjured and active prey. Most moving incident was late one night when on arrival home I found my Mantis shedding its skin. I watched, enthralled, for over an hour and I shall never forget seeing my Mantis gradually extend and spread its brand new rainbow-shimmering wings. Next day I released it onto a grapevine in my garden, the same garden in which I subsequently found a swarm of very tiny, recently hatched mantids! They are the cutest little creatures you could ever imagine.

- Q: Why plastic materials use glass fiber reinforced

- Some physical properties of plastic are generally worse than metal, adding glass fiber can improve the modulus of plastic products, but also can enhance the heat resistance of plastic products, but after adding glass fiber, the plastic will become more brittle, toughness decreased.

- Q: Can the cement board be affixed to the woodworking board?

- Why do not art glass cut off it? In the back of the cabinet for the glass, the cost will not be much higher, and beautiful. If the tile above the tile, it is necessary to use glass glue, damp after the board may be deformed, affecting the appearance of the tile is more likely to fall off.

- Q: How to remove the paint on the surface of the cement board

- And in the ground after the marble pavement, causing the door can not open. In addition to saw the short door, another way is to put the door up a few centimeters, so that the door up to move. This approach can ensure that the door is not shortened, but more laborious.

- Q: How does the cement pressure plate make a large brick? Specific steps and methods?

- With metal frame, paint brush outside the double-sided pressure plate fiber cement road off

- Q: How do I remove dried cement from door & running board?

- Try good ole' WD40 it's know to take tar and alot of other road grime off cars.

- Q: I'm getting my bathroom shower tile installed and was told to get 4 sheets 1/2 thick backerboard with screws and I need to know if there is a difference between Cement Board and Backer Board?

- Same thing. Backer board is a general term. Backer board can be 1/4 thick. can be a wood substrate used for tile is certain circumstances ( not yours), it can be the Hardi board which is a cementrous type board. Basically a backer board any thing that goes under any tile . You should get the cement board for your application. And if your doing a shower and he/she didn t suggest it, a vapor barrier is also needed under the cement board.in the shower area. Any questions you e mail me through my avatar and check my qualifications there. GL

Send your message to us

Non-Asbestos Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords