Monolithic Refractories Mesh Shape Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Shape Castable For Fireplace and Industrial Furnace

Product Description:

Mesh shape castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients. The Mesh shape castables are used high purity raw materials and additives as the main material, and made of under superfine powder adding technology.

Product Advantages:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, also has a fine working ability.They should be used with the same material products.They are widely used in various kinds of kiln lining.Such as boiler, blast furnace hot blast stove, heating furnace, ceramic kiln, etc.Furnaces of metallurgy industry, heat treatment furnace. Furnace of incineration of garbage, recirculating fluidized bed furnace. Furnaces of chemical industry and construction industry.

Product Applications:

For feature of Mesh shape castable, they have excellent abrasion resistance, thermal shock resistance, high-temperature resistance, anti-corrode and have high intensity.

Designed for refractory lining of blast furnace iron and slag runners, skimmers and soon

They can be used in troughs of small and mid size BFs and in all positions of the troughs where fast tapping is required.

Main Product Features:

1. High refractoriness, High refractoriness under load.

2. High density, low porosity.

3. Good slag resistance and corrosion resistance.

4. High strength and wear resistance.

5. Good resistance to flake performance.

6. Good thermal shock stability.

7. Scouring resistance

8. Good hot strength.

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

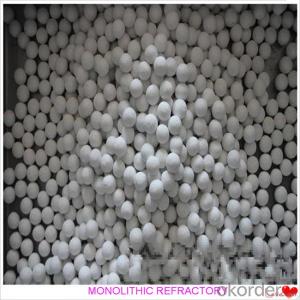

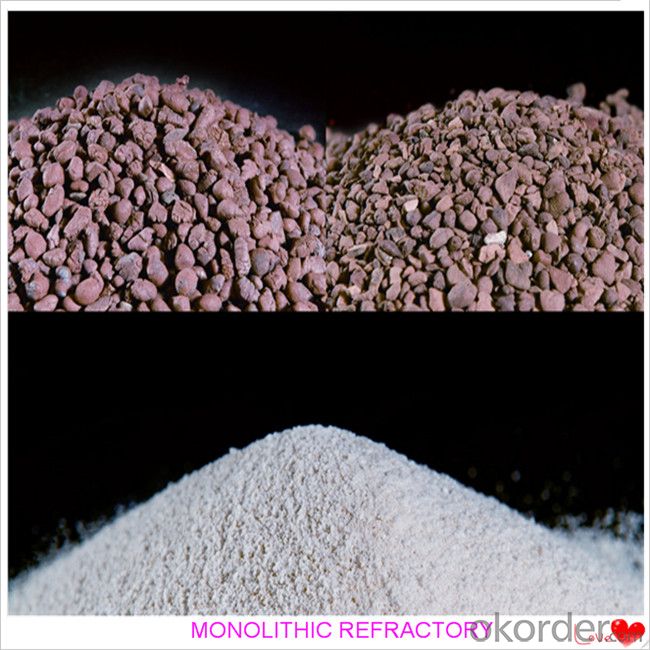

Product Picture:

- Q: How do monolithic refractories impact the overall productivity of iron and steel operations?

- Monolithic refractories have a significant impact on the overall productivity of iron and steel operations. These refractories are used to line the furnaces, ladles, and other high-temperature equipment, providing insulation and protection against extreme heat, chemical reactions, and mechanical wear. By ensuring the integrity and durability of these critical components, monolithic refractories enhance the efficiency and longevity of iron and steel production processes. They minimize downtime caused by frequent repairs or replacements, improve thermal management, and optimize energy consumption. Ultimately, the use of monolithic refractories leads to increased productivity, reduced costs, and improved quality control in iron and steel operations.

- Q: How are monolithic refractories different from traditional refractories?

- Monolithic refractories differ from traditional refractories in terms of their composition, installation method, and performance characteristics. To begin with, monolithic refractories consist of only one material, as their name suggests, while traditional refractories are typically comprised of multiple materials. This singular composition of monolithic refractories allows for greater control over their properties and performance. Moreover, the installation process for monolithic refractories differs from that of traditional refractories. Traditional refractories are typically installed in the form of bricks or precast shapes, which are assembled together to create the desired lining. In contrast, monolithic refractories are provided in a ready-to-use form, such as a dry mix or suspension, which is then poured, sprayed, or gunned into place. This facilitates a faster and more efficient installation of monolithic refractories. Lastly, monolithic refractories offer superior performance characteristics compared to traditional refractories. They possess improved thermal shock resistance, higher hot strength, and enhanced resistance to chemical attacks. Furthermore, they can be more easily repaired or patched compared to traditional refractories, which often necessitate the replacement of entire bricks or shapes. In conclusion, the key distinctions between monolithic refractories and traditional refractories lie in their composition, installation method, and performance characteristics. Monolithic refractories provide better control over properties, simpler installation, and superior performance, making them the preferred choice in numerous industrial applications.

- Q: How do monolithic refractories handle thermal expansion and contraction?

- Monolithic refractories are designed to handle the challenges of thermal expansion and contraction. These materials are composed of a single solid structure, as opposed to the traditional brick or tile forms of refractories. This unique composition allows monolithic refractories to better accommodate the thermal stresses associated with temperature changes. One way that monolithic refractories handle thermal expansion and contraction is through their ability to withstand high temperatures. These materials are typically engineered to have a high melting point, allowing them to maintain their structural integrity even under extreme heat conditions. This property helps to prevent the refractory from cracking or disintegrating due to thermal expansion. In addition, monolithic refractories often contain a binder or bonding agent that helps to hold the refractory particles together. This binder can be formulated to have a certain degree of flexibility, allowing the material to expand and contract without cracking or breaking. This flexibility helps to absorb the stresses caused by thermal expansion and contraction, ensuring the longevity and performance of the refractory. Furthermore, monolithic refractories can be applied in a way that allows for expansion and contraction. These materials can be installed with joints or gaps between sections, which can accommodate the movement caused by temperature changes. This technique, known as joint design or expansion joint systems, allows the refractory to expand and contract without causing damage to the overall structure. Overall, monolithic refractories are designed to handle thermal expansion and contraction by withstanding high temperatures, incorporating flexible binders, and using joint design techniques. These properties enable them to maintain their structural integrity and performance in extreme heat conditions, making them a reliable choice for applications that require resistance to thermal stress.

- Q: How do monolithic refractories protect the lining of ladles and tundishes?

- Monolithic refractories protect the lining of ladles and tundishes by forming a strong and durable barrier against high temperatures, chemical reactions, and mechanical stresses. These refractories are designed to be resistant to thermal shock and erosion, ensuring that the lining remains intact and unaffected by the molten metal or slag. They also provide insulation, minimizing heat loss and reducing energy consumption. Overall, monolithic refractories act as a reliable shield, extending the lifespan of the ladles and tundishes and preventing any detrimental effects on the lining.

- Q: What are the specific requirements of monolithic refractories for steel ladle purging applications?

- To ensure optimal performance and durability, monolithic refractories used in steel ladle purging applications must meet certain requirements. Firstly, they need to possess high thermal stability and resistance to thermal shock, as the steelmaking process involves extreme temperatures. This is crucial in order to prevent any cracking or spalling of the refractory lining. Additionally, monolithic refractories used for ladle purging applications should exhibit excellent corrosion resistance against molten steel and slag. They must be able to withstand the aggressive chemical environment without experiencing significant deterioration, as this could lead to contamination of the steel and negatively impact its quality. Another essential requirement is good erosion resistance. The refractories should be capable of withstanding the high velocity of the purging process, which involves the injection of argon or other gases into the ladle to remove impurities. This erosion resistance ensures that the refractory lining remains intact and does not wear away during operation. Furthermore, monolithic refractories for ladle purging applications should have low porosity and high density. This prevents the infiltration of molten steel and slag into the refractory lining, thus reducing the risk of thermal spalling and corrosion. Lastly, these refractories should exhibit good thermal conductivity in order to efficiently transfer heat from the steel to the refractory lining. This allows for better temperature control and energy efficiency during the purging process. Overall, the specific requirements for monolithic refractories in steel ladle purging applications include high thermal stability, corrosion resistance, erosion resistance, low porosity, high density, and good thermal conductivity. Meeting these requirements ensures that the refractories can withstand the harsh conditions of the steelmaking process, maintain their integrity, and contribute to the production of high-quality steel.

- Q: How do monolithic refractories contribute to the overall reliability of iron and steel processes?

- Monolithic refractories play a crucial role in enhancing the overall reliability of iron and steel processes in several ways. Firstly, they provide excellent thermal insulation, which helps in maintaining consistent and controlled temperatures within the furnaces and other equipment involved in the production process. This ensures the stability of the process and avoids any sudden temperature fluctuations that could lead to equipment failure or product quality issues. Secondly, monolithic refractories offer high resistance to thermal shocks and mechanical stresses, which are common in iron and steelmaking operations. These refractories can withstand extreme temperatures, rapid heating and cooling cycles, and the corrosive nature of molten metals, thereby prolonging the lifespan of the equipment and reducing the frequency of repairs or replacements. Moreover, monolithic refractories have a superior ability to resist chemical attacks from molten metals, slag, and other harsh substances encountered in iron and steel processes. This resistance prevents the refractories from deteriorating or corroding over time, ensuring their integrity and preventing any contamination of the metal being produced. Lastly, the use of monolithic refractories allows for greater design flexibility and ease of installation compared to traditional brick refractories. This flexibility enables the construction of complex shapes and structures, optimizing the efficiency and productivity of iron and steelmaking processes. Overall, monolithic refractories contribute significantly to the reliability of iron and steel processes by providing excellent thermal insulation, resistance to thermal shocks and chemical attacks, and facilitating flexible design and installation options.

- Q: What are the main factors affecting the erosion resistance of monolithic refractories?

- The main factors affecting the erosion resistance of monolithic refractories include the type and composition of the refractory material, the operating temperature and environment, the mechanical strength and density of the refractory, and the presence of impurities or contaminants. Additionally, the design and installation of the refractory lining, as well as the method of installation, can also influence its erosion resistance.

- Q: How do monolithic refractories improve the performance of ladles and tundishes?

- Monolithic refractories improve the performance of ladles and tundishes by providing superior thermal insulation, high mechanical strength, and resistance to chemical attacks and thermal shocks. These qualities enhance the overall durability and longevity of the ladles and tundishes, reducing the need for frequent repairs or replacements. Additionally, monolithic refractories offer better flow properties, facilitating smooth and efficient pouring of molten metal, while minimizing the risk of slag or metal infiltration. Overall, the use of monolithic refractories improves the efficiency, productivity, and cost-effectiveness of ladles and tundishes in various industrial applications.

- Q: What are the typical applications of monolithic refractories in blast furnaces?

- Monolithic refractories are widely used in blast furnaces due to their unique properties and applications. These refractories are composed of a single, homogeneous material that can be shaped and installed in various forms without the need for joints or seams. This characteristic makes them ideal for lining and protecting the different zones of a blast furnace. One typical application of monolithic refractories in blast furnaces is the lining of the hearth. The hearth is the bottom part of the furnace where molten iron and slag accumulate. Monolithic refractories are used to create a durable and heat-resistant lining that can withstand the extreme temperatures and chemical reactions occurring in this area. Another common application is the lining of the bosh, which is the transition zone between the hearth and the stack of the blast furnace. The bosh is subjected to high temperatures and mechanical stresses due to the movement of the burden materials. Monolithic refractories with high thermal shock resistance and abrasion resistance are used to ensure the longevity and efficiency of the bosh. Monolithic refractories are also used for the lining of the stack and the tuyere area. The stack is the vertical part of the furnace where the reduction of iron ore takes place. The tuyere area is where the hot blast of air is injected into the furnace. Both of these areas require refractories that can withstand high temperatures, chemical reactions, and mechanical stresses. Furthermore, monolithic refractories are used for repairs and maintenance in blast furnaces. Due to the harsh conditions inside the furnace, the lining may deteriorate over time. Monolithic refractories can be easily applied as patching materials to restore the integrity of the lining and extend the furnace's lifespan. In summary, the typical applications of monolithic refractories in blast furnaces include lining the hearth, bosh, stack, and tuyere area, as well as for repairs and maintenance. These refractories provide excellent thermal shock resistance, abrasion resistance, and durability, making them essential for the efficient operation of blast furnaces in the iron and steel industry.

- Q: What are the key factors to consider when designing the lining system with monolithic refractories?

- When designing a lining system with monolithic refractories, there are several key factors that need to be considered. Firstly, the operating conditions of the system need to be thoroughly assessed. Factors such as temperature, pressure, and chemical composition of the materials being processed should be taken into account. This will help determine the appropriate type of monolithic refractories to be used. Secondly, the physical and mechanical properties of the refractories should be considered. These include factors like thermal conductivity, thermal expansion, and mechanical strength. The refractories should have properties that are compatible with the specific requirements of the system to ensure optimal performance and longevity. Thirdly, the installation method and techniques need to be carefully planned. The lining system should be designed in a way that allows for proper installation and ensures a tight seal to prevent any leakage or infiltration. The installation process should also take into account factors like curing time and temperature to ensure the refractories achieve their desired properties. Lastly, the cost and availability of the refractories should be considered. It is important to choose refractories that are cost-effective and readily available in the market. This will help ensure that any maintenance or repairs can be done efficiently without causing significant downtime or additional expenses. By considering these key factors, a well-designed lining system with monolithic refractories can be implemented, providing optimal performance, durability, and cost-effectiveness for the specific application.

Send your message to us

Monolithic Refractories Mesh Shape Castable for Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords