Monolithic Refractories High Performance Ladle Slide Gate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

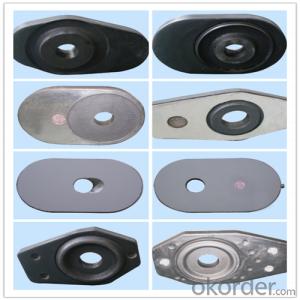

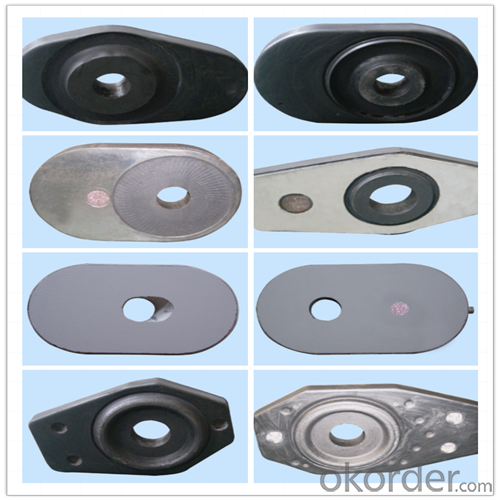

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

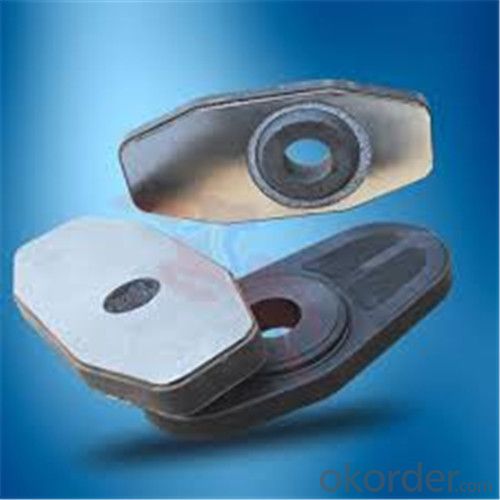

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Sample is on your request.

Welcome to visit our factory~

- Q: How do monolithic refractories contribute to the overall efficiency of ladle refining processes?

- The overall efficiency of ladle refining processes is greatly enhanced by the use of monolithic refractories. Ladle refining, a critical step in steelmaking, involves the removal of impurities and the addition of alloying elements to achieve the desired steel properties. Unshaped refractory materials, known as monolithic refractories, offer numerous benefits that contribute to the efficiency of this process. To begin with, monolithic refractories provide excellent thermal insulation. As ladle refining processes involve high temperatures, it is crucial for the refractories to withstand and contain these temperatures. Monolithic refractories have a low thermal conductivity, which minimizes heat loss from the ladle. This insulation helps maintain the desired temperature within the ladle, enabling efficient refining and reducing the energy required for heating. Furthermore, monolithic refractories exhibit high resistance to chemical attack and erosion. During ladle refining, the steel is exposed to various chemical reactions and corrosive elements. Monolithic refractories are specifically designed to withstand these harsh conditions, effectively protecting the ladle from chemical attack and erosion. This resistance ensures that the refractories maintain their structural integrity, preventing any contamination of the steel and extending the lifespan of the ladle. Additionally, monolithic refractories offer easy installation and repair. Unlike traditional brick refractories, monolithic refractories can be applied as a single, homogeneous layer, eliminating the need for complex bricklaying techniques. This ease of installation reduces downtime during ladle maintenance and repair, thus improving the overall efficiency of the refining process. Moreover, monolithic refractories can be easily patched or repaired as needed, further minimizing downtime and ensuring continuous operation. In conclusion, monolithic refractories play a significant role in enhancing the overall efficiency of ladle refining processes. Their exceptional thermal insulation properties, resistance to chemical attack and erosion, and ease of installation and repair all contribute to improving the efficiency and productivity of ladle refining. By providing a reliable and durable lining for the ladle, monolithic refractories help maintain the desired temperature, prevent contamination, and minimize downtime, ultimately resulting in improved quality and yield of the refined steel.

- Q: How do monolithic refractories perform in rotary hearth furnace applications?

- The performance of monolithic refractories in rotary hearth furnaces is well-known. These refractories are specifically designed to endure the extreme temperatures and harsh conditions found in these furnaces, making them the ideal choice for this particular application. One major advantage of monolithic refractories is their resistance to thermal shock. In rotary hearth furnaces, the material being processed is subjected to rapid heating and cooling cycles, which can cause significant stress on the refractory lining. Monolithic refractories have excellent thermal conductivity and low thermal expansion, enabling them to withstand these temperature fluctuations without cracking or spalling. Another important characteristic of monolithic refractories is their exceptional resistance to abrasion. In rotary hearth furnaces, the material being processed may contain abrasive particles that can wear down the refractory lining over time. Monolithic refractories are formulated with high-quality aggregates and binders that provide superior abrasion resistance, resulting in a longer lifespan for the lining. Moreover, monolithic refractories exhibit good chemical resistance, making them suitable for various applications in rotary hearth furnaces. They can withstand exposure to different chemical substances, such as molten metals, slags, and gases, without undergoing significant chemical reactions or degradation. This chemical stability ensures that the refractory lining remains intact and performs well in the demanding environment of a rotary hearth furnace. Additionally, monolithic refractories offer excellent flexibility during installation. Unlike traditional brick or tile refractories, which require complex installation procedures, monolithic refractories can be easily shaped and applied in-situ using methods like gunning, casting, or ramming. This flexibility allows for quicker and more efficient repairs or replacements of the lining, reducing downtime and maintenance costs. In conclusion, monolithic refractories are highly reliable and efficient in rotary hearth furnace applications. Their ability to withstand thermal shock, abrasion, and chemical attack, along with their easy installation, make them the preferred choice for lining materials in these demanding environments.

- Q: How do monolithic refractories withstand the thermal cycling in coke oven applications?

- Monolithic refractories are specifically designed to withstand the harsh conditions of thermal cycling in coke oven applications. Thermal cycling refers to the repetitive heating and cooling cycles that occur in these high-temperature environments. One of the key factors that enables monolithic refractories to withstand thermal cycling is their composition. They are typically made from a combination of different refractory materials, such as high-alumina, silica, and magnesia, which provide excellent thermal shock resistance. These materials have low thermal conductivity and high thermal expansion properties, allowing them to expand and contract without cracking or spalling under extreme temperature changes. Moreover, monolithic refractories have excellent bonding and adhesion properties, allowing them to form a strong and cohesive structure. This ensures that they can withstand the mechanical stresses caused by the thermal cycling process. Additionally, monolithic refractories can be installed in place through various techniques, such as gunning, casting, or ramming, which further enhances their resistance to thermal cycling. Furthermore, the presence of specialized additives and bonding agents in monolithic refractories improves their resistance to thermal cycling. These additives can enhance the refractory's ability to absorb thermal shock and minimize cracking, thus increasing its durability and longevity in coke oven applications. Overall, monolithic refractories' ability to withstand thermal cycling in coke oven applications can be attributed to their carefully formulated composition, strong bonding properties, and the incorporation of specialized additives. These characteristics make them highly reliable and suitable for the extreme temperature fluctuations experienced in coke oven operations.

- Q: What are the key innovations in monolithic refractories for the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories, which serve as lining materials in various high-temperature processes like blast furnaces, ladles, and converters. Over time, the field of monolithic refractories has witnessed several crucial innovations that address specific challenges and enhance the overall performance of these linings. Among the significant innovations in monolithic refractories is the emergence of low cement and ultra-low cement castables. These castables contain reduced cement quantities, resulting in improved properties such as higher hot strength, better thermal shock resistance, and enhanced resistance to chemical attack. By decreasing the cement content, the refractory achieves higher density, reduced porosity, and increased mechanical strength, ultimately leading to improved durability and extended service life. Another innovation in monolithic refractories is the introduction of self-flowing castables. These castables are designed to exhibit excellent flowability and can be conveniently installed through pouring or pumping, eliminating the need for manual vibration. Self-flowing castables offer advantages like reduced installation time, improved lining quality, and enhanced performance in complex geometries or hard-to-reach areas. In recent years, advances in nanotechnology have also influenced the development of monolithic refractories. Refractory compositions now incorporate nanoparticles, such as nano-sized additives and binders, to enhance their properties. These nanoparticles enhance the refractory's mechanical strength, thermal conductivity, and corrosion resistance. Additionally, nanotechnology enables better control over refractories' microstructure, resulting in optimized performance and increased lifespan. The development of high-performance monolithic refractories has also been driven by the need for improved energy efficiency and reduced environmental impact. Insulating castables, for instance, have been created to provide excellent thermal insulation properties, leading to reduced heat loss and energy consumption in various applications. These refractories contribute to increased energy efficiency, lowered production costs, and minimized greenhouse gas emissions. Moreover, advanced installation techniques like gunning and shotcreting have revolutionized the application of monolithic refractories. These techniques enable faster and more precise installation, reducing downtime and improving productivity. Additionally, robotic application systems have been introduced, allowing for automated and consistent refractory installation, ensuring high-quality linings with minimal human intervention. In conclusion, key innovations in monolithic refractories for the iron and steel industry encompass the development of low cement and ultra-low cement castables, self-flowing castables, the incorporation of nanotechnology, the introduction of high-performance insulation materials, and advancements in installation techniques. These innovations have significantly enhanced the performance, durability, energy efficiency, and installation processes of monolithic refractories, thereby contributing to the overall efficiency and competitiveness of the iron and steel industry.

- Q: What are the common testing methods used to evaluate the performance of monolithic refractories?

- The common testing methods used to evaluate the performance of monolithic refractories include thermal conductivity testing, hot modulus of rupture testing, abrasion resistance testing, thermal shock resistance testing, and corrosion resistance testing.

- Q: What are the cost implications of using monolithic refractories in the iron and steel industry?

- The use of monolithic refractories in the iron and steel industry can have various cost implications. Firstly, the initial cost of monolithic refractories tends to be higher compared to traditional brick refractories. Monolithic refractories are typically made from high-quality raw materials and require specialized installation techniques, leading to higher upfront expenses. However, these higher upfront costs can be offset by the benefits provided by monolithic refractories in terms of performance, durability, and reduced maintenance requirements. One of the major cost implications of using monolithic refractories is their extended service life. Monolithic refractories have excellent thermal shock resistance and can withstand high temperatures, mechanical stress, and corrosive environments. This results in reduced downtime and fewer replacement or repair needs, leading to overall cost savings in the long run. Additionally, monolithic refractories offer flexibility in design and application. They can be easily shaped and installed to fit complex geometries, resulting in optimized furnace linings and improved energy efficiency. By minimizing heat loss, monolithic refractories can reduce fuel consumption and lower energy costs for the iron and steel industry. Furthermore, the installation and maintenance of monolithic refractories can be less labor-intensive compared to brick refractories. This can result in reduced labor costs and shorter installation time, leading to potential cost savings for the industry. Another cost implication of using monolithic refractories is their impact on productivity. Monolithic refractories provide improved thermal insulation, reduced slag adhesion, and enhanced resistance to wear and erosion. These properties can lead to increased production rates, improved product quality, and minimized process interruptions, ultimately translating into higher profitability for iron and steel manufacturers. It is important to note that the cost implications of using monolithic refractories can vary depending on the specific application, furnace type, and operating conditions. Therefore, a thorough cost-benefit analysis should be conducted to evaluate the overall economic impact of implementing monolithic refractories in the iron and steel industry.

- Q: What are the main factors affecting the abrasion resistance of monolithic refractories?

- The main factors affecting the abrasion resistance of monolithic refractories are the composition of the refractory material, the size and shape of the abrasive particles, the velocity and angle of impact of the abrasives, and the temperature and pressure conditions in the application environment.

- Q: How are monolithic refractories installed and repaired in iron and steel production facilities?

- Monolithic refractories in iron and steel production facilities are installed by first preparing the surface by removing any existing refractory materials and cleaning it thoroughly. The monolithic refractory is then mixed with water to form a workable consistency and applied to the surface using various methods such as spraying, troweling, or casting. After installation, the refractory is allowed to cure and dry before being heated gradually to the desired operating temperature. In terms of repair, damaged or worn-out monolithic refractories are typically removed by chipping or cutting, and the surface is again cleaned. The new refractory material is then mixed and applied to the repaired area using the same techniques as installation. It is important to ensure proper curing and drying of the repaired refractory before subjecting it to heat. Regular inspection and maintenance are crucial to identify any potential issues and prevent major repairs or replacement in the future.

- Q: What are the specific requirements of monolithic refractories for continuous casting applications?

- To withstand the extreme temperatures and thermal shock conditions experienced during continuous casting, monolithic refractories have specific requirements. First and foremost, these refractories must possess high thermal conductivity, enabling them to efficiently transfer heat away from the molten metal and maintain a stable casting temperature. This is crucial in preventing the formation of defects such as cracks, hot spots, and uneven solidification in the cast product. Secondly, monolithic refractories for continuous casting applications need to exhibit high refractoriness. This means they can endure the high temperatures of the molten metal without melting or deforming, ensuring the refractories can provide a protective lining and maintain their structural integrity throughout the casting process. In addition, these refractories must demonstrate excellent resistance to thermal shock. The continuous casting process involves rapid cooling and heating cycles, resulting in significant temperature differentials and inducing thermal stresses. Monolithic refractories with low thermal expansion and high thermal shock resistance can endure these conditions without cracking or spalling. Moreover, good erosion and corrosion resistance are vital requirements for monolithic refractories in continuous casting applications. The molten metal and slag can be highly corrosive and abrasive, causing wear and chemical attack on the refractory lining. Therefore, refractories with high resistance to erosion and corrosion are essential to ensure the longevity and stability of the lining. Lastly, monolithic refractories for continuous casting applications should possess good workability and ease of installation. This allows for efficient and precise lining installation, minimizing downtime during maintenance or repairs. Overall, the specific requirements for monolithic refractories in continuous casting encompass high thermal conductivity, refractoriness, thermal shock resistance, erosion and corrosion resistance, as well as good workability. Fulfilling these requirements guarantees that the refractories effectively safeguard the casting equipment and maintain the quality of the cast products.

- Q: How do monolithic refractories contribute to reducing downtime in iron and steel plants?

- The use of monolithic refractories plays a vital role in minimizing downtime in iron and steel plants. They have several key advantages over traditional brick refractories. To begin with, monolithic refractories are highly adaptable and can be easily shaped and installed. This allows for faster repairs and replacements. In contrast to brick refractories, which require time-consuming and labor-intensive processes like bricklaying and mortar application, monolithic materials can be directly applied in a castable or gunning form. This significantly reduces the time needed for repairs. Furthermore, monolithic refractories offer better thermal insulation and resistance to thermal shocks, which are common in iron and steel plants. This improved thermal performance helps to maintain stable operating temperatures and prevents sudden temperature fluctuations that can lead to refractory failure and subsequent downtime. By minimizing these thermal shocks, monolithic refractories increase the overall lifespan of the refractory lining, reducing the need for frequent repairs. Moreover, monolithic refractories provide superior chemical resistance compared to traditional brick refractories. Iron and steel plants often face aggressive chemical environments due to the presence of molten metal, slag, and other corrosive substances. Monolithic refractories are specifically designed to withstand these harsh conditions, preventing chemical attacks and erosion of the refractory lining. As a result, the occurrence of unscheduled shutdowns due to refractory degradation is significantly reduced. Lastly, monolithic refractories offer better dimensional stability, minimizing the risk of cracks and spalling caused by thermal cycling and mechanical stress. This increased resistance to wear and tear ensures that the refractory lining remains intact for a longer period, reducing the frequency of maintenance and enhancing the overall operational efficiency of the iron and steel plant. In conclusion, monolithic refractories contribute to downtime reduction in iron and steel plants by providing faster installation, improved thermal insulation, superior chemical resistance, and enhanced dimensional stability. Their versatility and performance advantages make them a reliable choice for maintaining an efficient and dependable refractory lining, ultimately reducing the frequency and duration of plant shutdowns.

Send your message to us

Monolithic Refractories High Performance Ladle Slide Gate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords