Monolithic Refractories for Iron and Steel Industry - Painting Material for Tundish

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 Mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

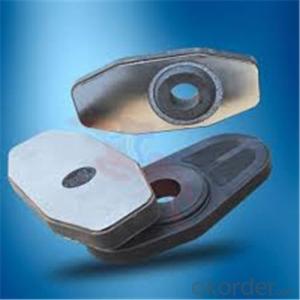

General Information of Painting Material for Tundish

Made as per international standards, ALRE painting material for tundish is known for its excellent corrosion resistance, long operating life and high refractoriness. Further, these can be provided in different specifications as required by the clients.

Technical data of Painting Material for Tundish

Item | Painting material for tundish | ||||

Al2O3 | % | ≥ | — | ||

MgO | % | ≥ | 60-85 | ||

CaO | % | ≤ | — | ||

SiO2 | % | ≤ | — | ||

SiO2+ Fe2O3+ Al2O3 | % | ≤ | |||

Bulk density ≥ | g/cm3 | 2.0 | |||

C.C.S. (MPa) ≥ | 110℃×24hrs | 5.0 | |||

1500℃×3hrs | 8.0 | ||||

M.O.R.(MPa) ≥ | 110℃×24hrs | — | |||

1500℃×3hrs | — | ||||

Refractoriness (℃) ≥ | — | ||||

Grain size (mm) ≤ | 3 | ||||

Permanent linear change | 1500℃×2hrs | — | |||

1500℃×3hrs | -2.5~-1.0 | ||||

Life time (hr) | 10-40 | ||||

Production line and Packing of Painting Material for Tundish

Feature of Painting Material for Tundish

Easy execution and mending

Excellent abrasive resistance performance

Excellent corrosion and scouring resistance of iron steel

Application of Painting Material for Tundish

ALRE painting material for tundish could be used widely for ladel and tundish of stell and iron industry.

- Q: How do monolithic refractories withstand the chemical attacks in copper smelting applications?

- Monolithic refractories have the ability to withstand chemical attacks in copper smelting applications due to their unique properties and composition. These refractories are specifically designed to resist the harsh and corrosive environment found in copper smelting processes. Firstly, monolithic refractories are made from high-quality materials such as alumina, silica, and magnesia, which have high melting points and are chemically stable. These materials are carefully selected to ensure they can withstand the corrosive effects of copper smelting, such as the presence of sulfur compounds and acidic gases. The refractory's composition also includes various additives and bonding agents that enhance its resistance to chemical attacks. Additionally, monolithic refractories have excellent thermal shock resistance, meaning they can withstand rapid temperature changes without cracking or spalling. In copper smelting applications, the extreme temperatures involved can cause thermal stress on the refractory lining. The refractories' ability to withstand these temperature fluctuations is crucial in preventing the formation of cracks and ensuring their long-term performance. Furthermore, monolithic refractories have a dense and compact structure, which provides an effective barrier against the penetration of molten copper and other corrosive substances. This dense structure prevents the chemical attacks from penetrating the refractory lining, thus ensuring its durability and longevity. Moreover, monolithic refractories offer superior erosion resistance, which is essential in copper smelting applications where high-velocity gases and molten metal flows can cause erosion of the refractory lining. The refractory's erosion resistance prevents the degradation of the lining and maintains its structural integrity. Overall, monolithic refractories are specially designed to withstand the chemical attacks encountered in copper smelting applications. By utilizing high-quality materials, incorporating additives, and possessing excellent thermal shock resistance, density, and erosion resistance, these refractories provide a reliable and durable lining that can withstand the harsh conditions of copper smelting processes.

- Q: What are the common failure modes of monolithic refractories in iron and steel applications?

- Monolithic refractories are widely used in iron and steel applications due to their excellent thermal shock resistance, high temperature stability, and mechanical strength. However, like any other material, they are not immune to failure. There are several common failure modes associated with monolithic refractories in iron and steel applications. 1. Spalling: Spalling is one of the most common failure modes of monolithic refractories. It refers to the detachment of refractory material from the surface due to thermal cycling, mechanical stress, or chemical reactions. Spalling can occur due to mismatched thermal expansion coefficients between the refractory and the surrounding structure, leading to cracking and subsequent detachment. 2. Erosion: Erosion is another prevalent failure mode in iron and steel applications. It occurs when the refractory material is subjected to the erosive action of molten metal, slag, or gases. The erosion can be a result of the physical impact of the flowing metal or the chemical attack by corrosive slag components. Erosion leads to the loss of refractory material, decreased lining thickness, and compromised performance. 3. Corrosion: Corrosion is a significant failure mode in iron and steel applications, particularly in contact with aggressive atmospheres or molten metal. Corrosion can result from chemical reactions between the refractory material and the corrosive agents, such as oxides, sulfides, or alkalis present in the environment. It leads to the formation of corrosion products, which can weaken the refractory lining and reduce its lifespan. 4. Thermal shock: Monolithic refractories are exposed to extreme temperature fluctuations in iron and steel applications. Rapid heating or cooling can lead to thermal shock, causing cracking and failure of the refractory material. Thermal shock can occur due to uneven heating or cooling, sudden changes in temperature, or thermal gradients within the refractory lining. 5. Abrasion: In certain iron and steel applications, monolithic refractories can be subjected to abrasive wear. This occurs when the refractory lining comes into contact with solid particles, such as metallic oxides, slags, or raw materials. The repeated impact and rubbing action of these particles can cause erosion and abrasion of the refractory material, leading to its failure. To mitigate these failure modes, proper refractory selection, installation techniques, and maintenance practices are crucial. Regular inspection, repair of damaged areas, and application of protective coatings can help extend the lifespan and performance of monolithic refractories in iron and steel applications.

- Q: What are the quality control measures for monolithic refractories in the iron and steel industry?

- To ensure the efficiency and safety of the production process in the iron and steel industry, it is crucial to implement quality control measures for monolithic refractories. These measures encompass a range of inspections and tests throughout the manufacturing and installation stages. To begin with, rigorous testing is conducted on the raw materials used for monolithic refractories. This involves analyzing the chemical composition, particle size distribution, and impurity content. These tests are essential to ensure that the ingredients meet the required specifications and are suitable for the intended application. During the production process, the focus of quality control measures lies in monitoring the mixing and blending of the materials. This ensures that a homogeneous mixture is achieved, preventing any inconsistencies in the final product. Additionally, the density and viscosity of the refractory castables or plastics are checked to maintain the desired physical properties. Once the monolithic refractories are manufactured, they undergo several performance tests. These tests involve determining properties such as cold crushing strength, modulus of rupture, and thermal conductivity. These characteristics are crucial in ensuring that the refractories can withstand the extreme temperatures and mechanical stress present in the iron and steel industry. Aside from laboratory testing, quality control measures also involve on-site inspections during installation. This includes verifying the correct application techniques, such as proper vibration, curing, and drying procedures. It is of utmost importance to ensure that the monolithic refractories are applied correctly to achieve optimal performance and longevity. Furthermore, regular sampling and monitoring of the refractories' performance are carried out during operation. This allows for the early detection of any signs of degradation or wear, enabling proactive maintenance and replacement before any significant issues arise. In conclusion, the quality control measures for monolithic refractories in the iron and steel industry encompass comprehensive testing, monitoring, and inspection procedures. These measures are implemented to guarantee the reliability, durability, and efficiency of the refractories, ultimately contributing to the smooth operation of the iron and steel production processes.

- Q: How do monolithic refractories impact the quality and performance of iron and steel products?

- The quality and performance of iron and steel products rely heavily on monolithic refractories. These refractories are designed to withstand extreme temperatures and harsh conditions, making them indispensable in the iron and steel industry. To begin with, monolithic refractories contribute to the overall quality of iron and steel products by providing exceptional thermal insulation. They help maintain a consistent and controlled temperature during the manufacturing process, which is especially crucial in blast furnaces where temperatures can reach up to 2,000 degrees Celsius. By effectively insulating the furnace walls, monolithic refractories minimize heat loss and ensure efficient energy utilization. As a result, the products have higher quality and improved mechanical properties. Additionally, monolithic refractories offer superior resistance to chemical and physical wear. In the steelmaking process, the molten metal and slag can be highly corrosive, leading to erosion and deterioration of the refractory lining. However, monolithic refractories are engineered to withstand such aggressive environments, providing excellent resistance to chemical attack and mechanical stress. By preserving the integrity of the lining, they prevent contamination and extend the lifespan of the furnace or ladle, ultimately enhancing the quality of the final iron and steel products. Moreover, monolithic refractories allow for greater design flexibility and ease of installation. Unlike traditional refractory bricks that require precise placement and fitting, monolithic refractories can be applied as a single, cohesive material. This enables the creation of more intricate shapes and structures, optimizing furnace design and enhancing thermal efficiency. Additionally, the ease of installation reduces downtime during maintenance and repairs, ensuring uninterrupted production and minimizing disruptions to the manufacturing process. In conclusion, monolithic refractories have a significant impact on the quality and performance of iron and steel products. They provide exceptional thermal insulation, resist chemical and physical wear, and offer greater design flexibility. By maintaining consistent temperature environments, preventing contamination, and enabling efficient production processes, monolithic refractories contribute to the production of high-quality iron and steel products that meet the rigorous demands of various industries.

- Q: How do monolithic refractories resist chemical corrosion in iron and steel applications?

- Monolithic refractories resist chemical corrosion in iron and steel applications through their inherent properties and composition. They are designed to have high chemical stability and resistance to react with molten metals, slag, and other corrosive substances present in these applications. Additionally, monolithic refractories are usually formulated with specific additives and binders that enhance their resistance to chemical attack. This combination of properties and composition allows them to withstand the aggressive environment of iron and steel applications without significant degradation or corrosion.

- Q: How do monolithic refractories withstand high temperatures in iron and steel production?

- Monolithic refractories are specially designed to withstand the high temperatures encountered in iron and steel production. These refractories are made from a single piece or a single material, unlike traditional brick refractories that are made by laying bricks one by one. The ability of monolithic refractories to withstand high temperatures is due to their unique composition and structure. They are made from high-quality raw materials such as alumina, magnesia, silica, and carbon, which have high melting points and excellent heat resistance. The monolithic refractory is typically mixed with a binder, such as clay or cement, to give it shape and strength. This binder helps to hold the refractory particles together and provides the necessary structure to withstand thermal stresses. Additionally, various additives and additives can be included in the mix to further enhance the refractory properties. During iron and steel production, the monolithic refractories are exposed to extreme temperatures, rapid heating, and cooling cycles, as well as chemical reactions with molten metals and slag. However, the unique composition and structure of monolithic refractories enable them to endure these harsh conditions. The high melting point materials used in monolithic refractories prevent them from melting or deforming under the intense heat of iron and steel production. These materials have excellent thermal conductivity, allowing them to effectively transfer heat away from the hot surfaces, thus preventing overheating and damage. Furthermore, the binders and additives in monolithic refractories help to increase their resistance to thermal shock, which occurs when there is a rapid change in temperature. This resistance is crucial in iron and steel production since the refractories are frequently exposed to extreme temperature differentials. Lastly, the monolithic nature of these refractories eliminates the joints and gaps found in traditional brick refractories. The absence of joints minimizes the risk of heat leakage and infiltration of molten metal or slag, ensuring a more efficient and durable lining. In conclusion, monolithic refractories are specifically designed to withstand the high temperatures encountered in iron and steel production. Their composition, structure, and unique properties enable them to endure extreme heat, rapid temperature changes, chemical reactions, and thermal stresses, making them essential components in the manufacturing of iron and steel.

- Q: What are the considerations for repairing and patching monolithic refractories?

- When it comes to repairing and patching monolithic refractories, there are several important considerations that need to be taken into account. Firstly, it is crucial to carefully assess the extent and severity of the damage or deterioration. This will help determine the appropriate repair method and materials needed. Small cracks or minor damage may only require a simple patching or sealing, while larger or more severe damage might necessitate a complete replacement or a more extensive repair process. Secondly, the type of monolithic refractory material being used is an important factor to consider. Different types of monolithic refractories have varying properties and characteristics, such as thermal conductivity, chemical resistance, and mechanical strength. Therefore, it is crucial to choose a repair material that is compatible with the existing refractory material to ensure proper bonding and performance. Another consideration is the operating conditions and environment in which the monolithic refractory is exposed. Factors such as temperature, pressure, chemical exposure, and abrasion can significantly impact the durability and longevity of the refractory material. Understanding these conditions will help in selecting the appropriate repair materials and techniques that can withstand and perform well under these specific conditions. Additionally, the repair process should be carried out by experienced personnel who are knowledgeable about refractory materials and their installation. Improper repairs can lead to further damage or reduced performance, so it is essential to have skilled professionals who can perform the repair work correctly. Lastly, regular inspection and maintenance of the monolithic refractories are essential to detect any potential damage or deterioration early on. Timely repairs and patching can prevent further deterioration and extend the service life of the refractory material. In summary, considerations for repairing and patching monolithic refractories involve assessing the extent of damage, selecting compatible repair materials, understanding the operating conditions, employing skilled personnel, and conducting regular inspections and maintenance. By taking these factors into account, one can ensure effective repairs and the continued performance of monolithic refractories.

- Q: How do monolithic refractories resist chemical attack from molten metals and slags?

- Monolithic refractories resist chemical attack from molten metals and slags due to their chemical composition and structure. They are typically designed with high levels of resistance to corrosion and erosion, making them suitable for harsh environments. Additionally, they have low porosity, which reduces the penetration of molten metals and slags into the refractory material. The presence of certain additives and bonding agents further enhances their chemical resistance, preventing reactions between the refractory and the molten substances. Overall, monolithic refractories offer a strong barrier against chemical attack, ensuring their durability and longevity in such demanding conditions.

- Q: What are the common applications of monolithic refractories in blast furnaces?

- Monolithic refractories are commonly used in blast furnaces for various applications such as lining and repairing the hearth, taphole, and slag line, as well as for hot repairs and maintenance. These refractories provide high-temperature resistance, erosion and corrosion resistance, and thermal shock resistance, thereby ensuring the efficient and reliable operation of blast furnaces in the iron and steel industry.

- Q: What are the benefits of using monolithic refractories in the iron and steel industry?

- There are several benefits of using monolithic refractories in the iron and steel industry. Firstly, monolithic refractories offer excellent thermal shock resistance, allowing them to withstand extreme temperature changes without cracking or spalling. This is crucial in the iron and steel industry, where materials are subjected to high temperatures during processes like melting, casting, and heat treatment. Secondly, monolithic refractories have superior corrosion resistance, making them highly durable against the corrosive effects of molten metals and slag. This is particularly important in the iron and steel industry, where materials come into contact with aggressive molten iron, steel, and various chemical compounds. Additionally, monolithic refractories provide excellent mechanical strength and abrasion resistance. They have the ability to withstand mechanical stress, vibrations, and impacts typically encountered in the iron and steel industry. This ensures longer refractory lifespan, reduces downtime for repairs or replacements, and improves overall operational efficiency. Moreover, monolithic refractories offer ease of installation and repair. Unlike traditional refractory bricks that require complex and time-consuming masonry work, monolithic refractories can be installed quickly and easily using simple methods like casting, gunning, or spraying. This saves time and labor costs during initial installation and subsequent maintenance or repairs. Furthermore, monolithic refractories provide flexibility in design and application. They can be tailored to specific shapes and sizes, allowing for customized linings in different parts of the iron and steel manufacturing process. This versatility enhances the overall efficiency and effectiveness of refractory linings, optimizing the production output and ensuring consistent quality of the finished iron and steel products. In conclusion, the benefits of using monolithic refractories in the iron and steel industry are numerous. They offer exceptional thermal shock resistance, corrosion resistance, mechanical strength, and abrasion resistance. They are easy to install and repair, and their flexibility allows for customized designs. Overall, monolithic refractories contribute to improved productivity, reduced downtime, and enhanced product quality in the iron and steel industry.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Painting Material for Tundish

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 Mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords