Ramming Material-REFRACTORY

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

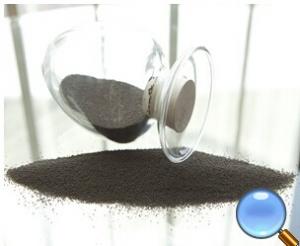

Silicon carbide, graphite, electrically calcined anthracite as raw material, adding a variety of ultrafine powder additives, fused cement or composite resin as binder made of bulk material.Used to populate the furnace body cooling equipment and masonry clearance or masonry leveling layer with a filling material.Ramming material good chemical stability, resistance to erosion and abrasion resistance, spalling resistance, thermal shock, widely used in metallurgy, building materials, non-ferrous metal smelting, chemical industry, machinery manufacturing industry!

Acidic, neutral and alkaline ramming material is widely used in the coreless medium frequency furnace, induction furnace, the ramming material as medium frequency furnace for melting grey cast iron, ductile iron, can be calcined cast iron, vermicular cast iron and cast iron alloy, molten carbon steel, alloy steel, high manganese steel, tool steel, heat-resistant steel, stainless steel, melted aluminum and its alloy, melting copper, brass, copper and bronze, copper alloy, etc

The product quality of quartz with coreless induction furnace refractories, acidic material.Adopt high purity microcrystalline silicon ore as raw material, improved the expansion disadvantages of furnace lining, lining rises obviously decrease when the oven, no crack when cold furnace. It is characterized by high purity raw materials, reasonable distribution, thermal shock resistance, suitable for medium and small batch of medium frequency induction furnace operation.The materials department of premixed concrete is dry mixture, according to the customer demand has good preparation boric acid or boron anhydride content, users can be directly put into use.

A, technical data (chemical composition does not contain sintering agent)

SiO2 CaO + MgO style acuities were 98.5% and 0.1% or higher Fe2O3 0.2% or less

Material density: 2.1 g/cm3 granularity: no more than 8.1 mm

Highest use temperature: 1700 ℃ construction methods: dry or dry dao.

Second, furnace building, firing and sintering process

Right furnace building, firing and sintering process is the key to guarantee the normal work of the furnace lining, before the furnace building and oven, please refer to the bright gold mining processing plant furnace building oven sintering process specification and the extension of the intermediate frequency induction furnace lining life of the furnace building process to explore ".

Three, packing and storing method

Multilayer moistureproof paper and lining packing 25 kg/bag.

- Q: The research direction of unshaped refractory for cement kiln

- Setting the product includes: alkali brick, high alumina brick, spalling resistance of silicon carbide brick, magnesia chrome brick, dolomite brick, spinel brick; unshaped products include: high strength alkali resistant castable, high alumina castable, mullite castable, corundum, spinel castable, silicon carbide castable etc..

Send your message to us

Ramming Material-REFRACTORY

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords