Checker Plate Aluminum Sheets for Mill Finished Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminium Sheets for Curtain Walls

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminium Sheets for Curtain Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminium Sheets for Curtain Walls

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

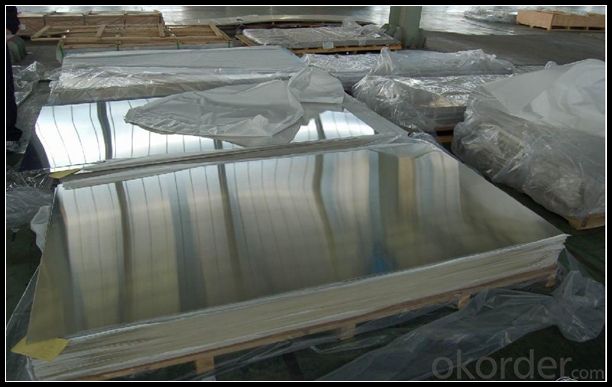

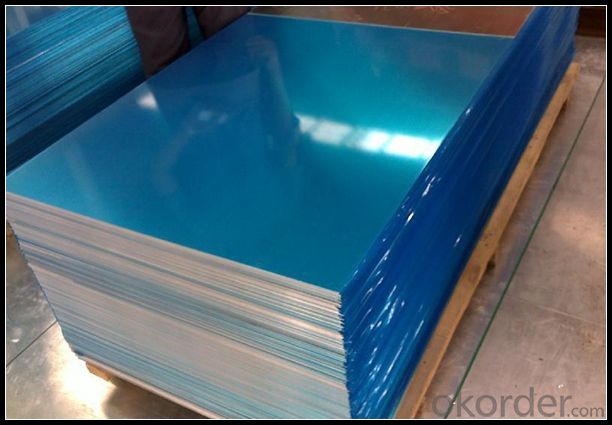

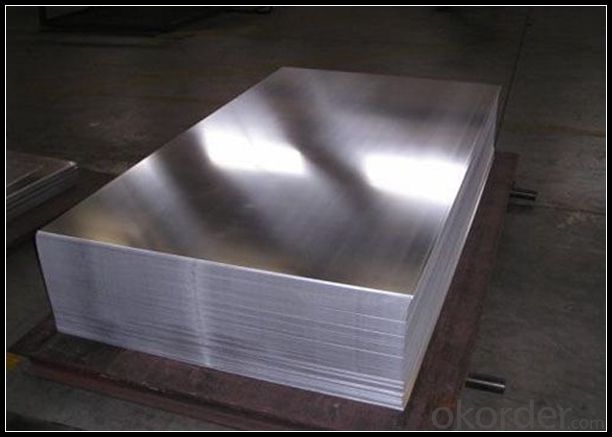

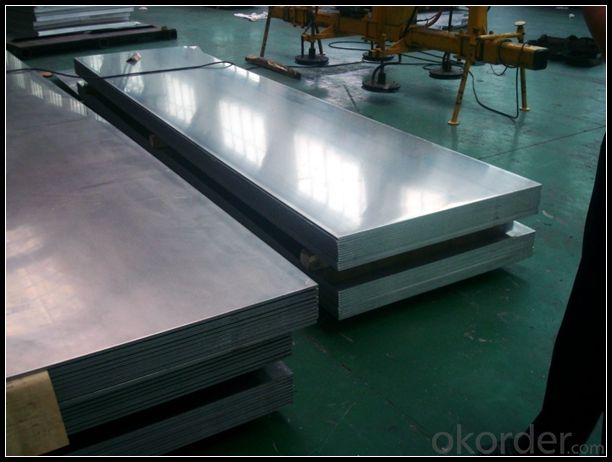

5. Image of Mill Finished Aluminium Sheets for Curtain Walls

6. Package and shipping of Mill Finished Aluminium Sheets for Curtain Walls

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is an aluminium plate? What is the difference between carbon steel sheet, galvanized sheet and stainless steel plate?What is the order of the price? Thank you

- Aluminized sheet, the full name of aluminum plating, also known as aluminized steel plate, also known as hot dipped aluminum plate.Aluminized steel plate is an aluminum silicon alloy coating steel plate, in which the aluminum content is 90%, silicon 10%. The aluminized steel plate has good heat resistance, heat reflection and corrosion resistance. Its mechanical and physical properties are better than those of cold-rolled steel sheet. Because of the superior performance of aluminized steel sheet, it has been widely used in our daily necessities. Such as car muffler, household appliances and so on.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- it firstly etches off the oxide on the surface of aluminum, and then reacts with aluminum, generating bubble.

- Q: Are aluminum sheets suitable for elevator interiors?

- Yes, aluminum sheets are suitable for elevator interiors. Aluminum is a durable and lightweight material that is resistant to corrosion, making it ideal for use in elevator interiors. It can be easily customized and offers a sleek and modern aesthetic. Additionally, aluminum is easy to clean and maintain, making it a practical choice for elevator interiors.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot can vary depending on the thickness or gauge of the sheet. On average, a 1/8 inch thick aluminum sheet weighs around 1.9 pounds per square foot. However, thinner sheets may weigh less, while thicker sheets can weigh more. It is important to consider the specific thickness of the aluminum sheet when determining its weight per square foot.

- Q: I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- The old tin ones and bottles hurt when you smash them on your forehead

- Q: 6061-T6 can aluminum sheets be bent?

- Landlord problem solving, no, I'm with you the same situation, into a batch of 2mm thick black, bending no problem, 3mm shine fold, 90 degrees bend ninety percent off break, I use punch press die bending

- Q: Are 101 aluminum sheets suitable for heat sinks?

- No, 101 aluminum sheets are not suitable for heat sinks. Heat sinks are designed to dissipate heat and therefore require materials with high thermal conductivity. 101 aluminum has a lower thermal conductivity compared to other aluminum alloys commonly used for heat sinks, such as 6061 or 6063. These alloys have better thermal conductivity properties, allowing them to effectively transfer heat away from the heat source. Therefore, it is recommended to use aluminum alloys specifically designed for heat sinks to ensure optimal heat dissipation and cooling performance.

- Q: What are the aluminum plates for?

- Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate. Aluminum plate is widely used in construction, packaging, air conditioning, refrigerators, solar energy, cosmetics and other industries, but also can be used in power plants, chemical plants, petrochemical plants, anti-corrosion, insulation and so on.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be bent or formed into different shapes through processes such as bending, rolling, or pressing, due to its malleability and ductility.

Send your message to us

Checker Plate Aluminum Sheets for Mill Finished Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords