Mill Finished Aluminum Sheets for Curtain Wall in Massachusetts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Mill Finished Aluminium Sheets for Curtain Wall

Mill Finished Aluminium Sheets for Curtain Wall are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed.

With the above features, Mill finished aluminum sheets are widely used in curtain walls, especially in Middle East, South East Asia, etc.

2.Main Features of Mill Finished Aluminium Sheets for Curtain Wall

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

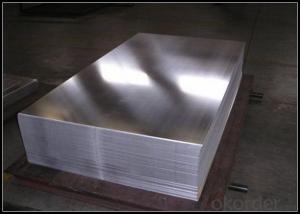

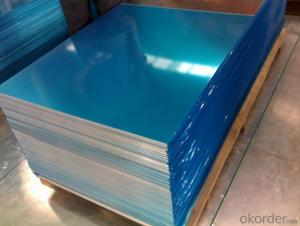

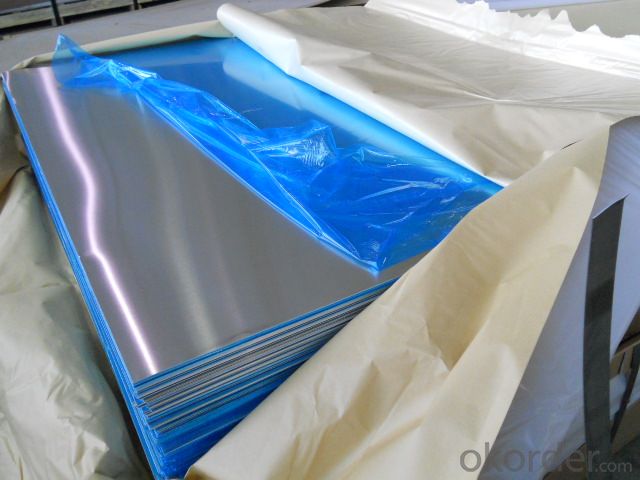

3. Mill Finished Aluminium Sheets for Curtain Wall Images

4.Specification of Mill Finished Aluminium Sheets for Curtain Wall

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- Death Cab For Cutie's What Sarah Said: And It Came To Me Then That Every Plan Is A Tiny Prayer To Father Time As I Stared At My Shoes In The Icu That Reeked Of Piss And 409 And I Rationed My Breathes As I Said To Myself That I'd Already Taken Too Much Today As Each Descending Peak Of The Lcd Took You A Little Farther Away From Me Away From Me Amongst The Vending Machines And Year-old Magazines In A Place Where We Only Say Goodbye It Stung Like A Violent Wind That Our Memories Depend On A Faulty Camera In Our Minds But I Knew That You Were A Truth I Would Rather Lose Than To Have Never Lain Beside At All And I Looked Around At All The Eyes On The Ground As The Tv Entertained Itself 'cause There's No Comfort In The Waiting Room Just Nervous Pacers Bracing For Bad News And Then The Nurse Comes Round And Everyone Will Lift Their Heads But I'm Thinking Of What Sarah Said That love Is Watching Someone Die

- Q: Can aluminum sheets be used for air conditioning systems?

- Yes, aluminum sheets can be used for air conditioning systems. Aluminum is a popular material choice for air conditioning components due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It is commonly used for manufacturing air conditioner coils, fins, and heat exchangers.

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: This question asks for the various types of surface treatments or coatings that can be applied to aluminum profiles to enhance their properties or appearance.

- <p>Aluminum profiles can be coated with several types of finishes to improve their aesthetic appeal, durability, and corrosion resistance. The common types include: 1) Anodizing, which creates a protective oxide layer on the aluminum surface; 2) Powder coating, where a dry powder is electrostatically applied and then cured under heat; 3) Electrophoretic coating, a method where charged particles adhere to the aluminum and then harden; 4) PVDF (Polyvinylidene Fluoride) coating, known for its excellent weather resistance and durability; 5) Thermal spraying, where a coating material is melted and sprayed onto the aluminum surface; and 6) Painting, which can be done through various methods such as airless spray or dip coating. Each type of coating serves different purposes and has its own set of advantages and applications.</p>

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Aluminum sheets have the capability to be utilized in pharmaceutical lab equipment. Aluminum, a versatile material, offers numerous benefits for pharmaceutical applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity make it an excellent option for constructing trays, shelves, and cabinets that are employed for storing and transporting pharmaceutical substances. Moreover, aluminum can be easily sterilized and cleaned, which is vital for maintaining hygienic conditions in pharmaceutical laboratories. Nevertheless, it is crucial to acknowledge that specific pharmaceutical procedures may demand materials that comply with particular regulatory standards. Thus, it is always wise to seek advice from industry experts or regulatory bodies to ensure that the selected aluminum sheets fulfill the necessary requirements for their intended usage in pharmaceutical lab equipment.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: What are some common applications of aluminum sheets?

- Due to their unique properties, aluminum sheets find a wide range of applications. Some of the common uses of aluminum sheets include the following: 1. Construction: Aluminum sheets are extensively utilized in the construction industry for roofing, siding, and window frames. Their lightweight nature and durability make them an ideal choice for these purposes. 2. Automotive industry: Aluminum sheets play a crucial role in the automotive industry, where they are used to manufacture car bodies, panels, and components. The lightweight nature of aluminum aids in reducing the overall weight of vehicles, thereby enhancing fuel efficiency. 3. Packaging: Aluminum sheets are widely employed for packaging, particularly in the food and beverage industry. Their ability to preserve the freshness and quality of packaged products makes them suitable for producing cans, foils, and lids. 4. Aerospace industry: The aerospace industry heavily relies on aluminum sheets for manufacturing aircraft bodies, wings, and structural components. This is due to their high strength-to-weight ratio, resistance to corrosion, and capability to withstand extreme temperatures. 5. Electrical industry: Aluminum sheets find various applications in the electrical industry, including the production of electrical enclosures, transformers, and bus bars. The excellent conductivity and lightweight properties of aluminum make it a preferred choice for these purposes. 6. Marine industry: The marine industry extensively uses aluminum sheets for constructing boats, ship hulls, and other marine structures. Aluminum's resistance to corrosion and ability to withstand harsh marine environments make it a suitable material for these applications. 7. Decorative purposes: Aluminum sheets are commonly utilized for decorative purposes in architecture and interior design. They can be shaped, engraved, or coated with different finishes to create aesthetically pleasing surfaces for walls, ceilings, furniture, and signage. These examples highlight just a few of the many applications of aluminum sheets. The versatility, durability, and lightweight nature of aluminum make it highly sought-after in various industries.

- Q: How do you bend aluminum sheets?

- In order to bend aluminum sheets, one must have a few tools and employ the correct technique. Here is a step-by-step manual on how to bend aluminum sheets: 1. Acquire the necessary tools: You will require a metal brake, which is a specialized tool intended for bending metal sheets, as well as a straight edge such as a ruler or a piece of wood. 2. Measure and indicate the bending line: Determine the desired location for the bend on the aluminum sheet and employ a measuring tape to mark the line. Ensure that the line is straight and precise. 3. Position the aluminum sheet: Place the aluminum sheet onto the metal brake, aligning the marked bending line with the brake's edge. Ensure that the sheet is secure and will not shift during the bending process. 4. Adjust the metal brake: Depending on the thickness of the aluminum sheet, modify the metal brake to the appropriate bending angle. This can typically be accomplished by loosening or tightening the clamps or screws on the brake. 5. Bend the aluminum sheet: Apply pressure to the metal brake, gradually bending the aluminum sheet along the marked bending line. Begin from one end and progress towards the other, ensuring a smooth and uniform bend. 6. Inspect the bend: Following the bending process, double-check the angle and alignment to confirm that it corresponds to your desired specifications. If necessary, make any necessary adjustments before proceeding. 7. Repeat if necessary: If you require multiple bends on the aluminum sheet, repeat the process for each one. Take your time and exercise patience in order to achieve the desired outcomes. It is important to note that the thickness and type of aluminum sheet may necessitate modifications to the bending technique. Thicker sheets may require increased pressure or multiple passes to achieve the desired bend. Always refer to the specific instructions and recommendations provided by the manufacturer of your metal brake for optimal results.

- Q: How does aluminum sheet perform in extreme temperatures?

- Aluminum sheet performs well in extreme temperatures as it has a high melting point of 660°C (1220°F) and exhibits excellent thermal conductivity. It can withstand both hot and cold temperatures without significant deformation or structural damage, making it suitable for various applications in extreme environments.

Send your message to us

Mill Finished Aluminum Sheets for Curtain Wall in Massachusetts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords