Mill Finish Aluminum Sheet for Building Curtain Wall with Bitumen Sheets Aluminum Backing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet for Building Curtain Wall

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet for Building Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet for Building Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

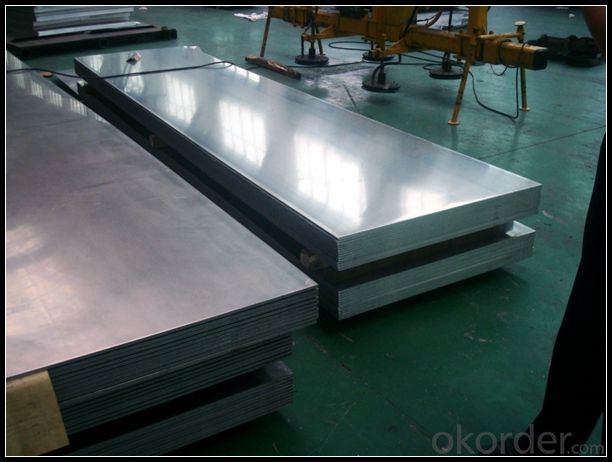

5. Image of Mill Finish Aluminum Sheet for Building Curtain Wall

6. Package and shipping of Mill Finish Aluminum Sheet for Building Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Absolutely, aluminum sheets are a perfect fit for the production of electronic components. Aluminum, being a lightweight, durable, and reasonably priced material, finds extensive usage in the electronics sector. Its remarkable electrical conductivity is crucial for the efficient operation of electronic devices. Moreover, aluminum sheets can effortlessly be molded, trimmed, and fashioned into diverse components like heat sinks, enclosures, and connectors. Furthermore, aluminum boasts commendable thermal conductivity, enabling it to proficiently disperse heat generated by electronic components. Consequently, aluminum sheets emerge as an optimal selection for the manufacturing of electronic components.

- Q: Hey.How come iron rust and aluminium does not?DETAILED ANSWER PLEASE.I want to understand this...THANKS.

- Rust And Aluminum

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: Can aluminum sheets be recycled?

- Yes, aluminum sheets can be recycled. Aluminum is a highly recyclable material, and recycling aluminum sheets helps in conserving natural resources and reducing energy consumption compared to producing new sheets from raw materials.

- Q: Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a lightweight, non-toxic, and corrosion-resistant material that provides an effective barrier against moisture, oxygen, and light. It helps preserve the quality, taste, and freshness of food products, making it a popular choice for packaging perishable items. Additionally, aluminum is recyclable, making it an environmentally-friendly option for food packaging.

- Q: What is the electrical conductivity of 101 aluminum sheets?

- The electrical conductivity of 101 aluminum sheets can be influenced by a range of factors including the individual thickness of each sheet, the level of purity in the aluminum, and the potential presence of impurities or alloying elements. Typically, aluminum is recognized for its relatively superior electrical conductivity when compared to other metals. Nevertheless, without specific details regarding these aforementioned factors, it becomes challenging to provide an exact measurement for the electrical conductivity of 101 aluminum sheets.

- Q: What are the different methods of surface laminating aluminum sheets?

- There exist various techniques for surface laminating aluminum sheets, each with its own distinct advantages and suitability for different purposes. Some of the commonly utilized methods comprise: 1. Adhesive bonding: This involves the application of an adhesive layer between the aluminum sheet and the desired surface material. The adhesive is typically cured through the application of heat or pressure, resulting in a robust bond. This technique is versatile and can be employed with a range of surface materials, including wood, plastic, or glass. 2. Roll bonding: Also referred to as cladding or cold roll bonding, this method entails placing the aluminum sheet between two other metal sheets and subjecting them to high pressure to create a solid bond. Roll bonding is frequently employed in the production of composite materials, such as aluminum-clad steel sheets. 3. Thermal spraying: This process entails melting or heating aluminum powder and using a thermal spray gun to spray it onto the sheet surface. The molten aluminum solidifies upon contact, forming a durable coating. Thermal spraying is commonly used for corrosion protection or as a foundation layer for subsequent surface treatments. 4. Powder coating: In this technique, a dry powder paint is electrostatically applied to the surface of the aluminum sheet. The sheet is then heated, causing the powder to melt and form a smooth and protective coating. Powder coating offers exceptional durability, impact resistance, and a wide array of color options. 5. Anodizing: Anodization is an electrochemical process that enhances the natural oxide layer on the surface of aluminum sheets. By immersing the sheet in an electrolytic bath and applying an electric current, a controlled oxide layer is formed, providing corrosion resistance, improved adhesion for paint or adhesive, and aesthetic finishes. 6. Lamination with protective films: A plastic protective film can be applied to the surface of the aluminum sheet for safeguarding purposes during transportation, handling, or processing. These films offer temporary protection against scratches, abrasions, and dirt. These represent just a few among many techniques available for surface laminating aluminum sheets. The choice of method depends on factors such as desired properties, intended use, and specific application requirements.

- Q: How do you bend aluminum sheets?

- To bend aluminum sheets, you can use a variety of methods such as using a bending machine, a brake press, or even hand tools like a mallet and a block of wood. The process typically involves clamping the sheet securely, applying gradual pressure to the desired bending point, and manipulating the metal until the desired angle is achieved. It is important to take into consideration the thickness of the sheet and use appropriate techniques to avoid damaging or cracking the aluminum.

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile and efficient method that can be used to cut through a wide range of materials, including aluminum.

Send your message to us

Mill Finish Aluminum Sheet for Building Curtain Wall with Bitumen Sheets Aluminum Backing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords