Metallic Material Steel Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Metallic Material Steel Iron Rods for Construction Concrete

Description of Metallic Material Steel Iron Rods

1, Diameter: 5.5mm-10mm Metallic Material Steel Iron Rods

10m- 40mm Metallic Material Steel Iron Rods

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Metallic Material Steel Iron Rods

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

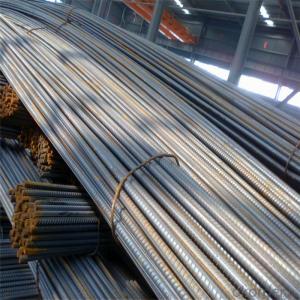

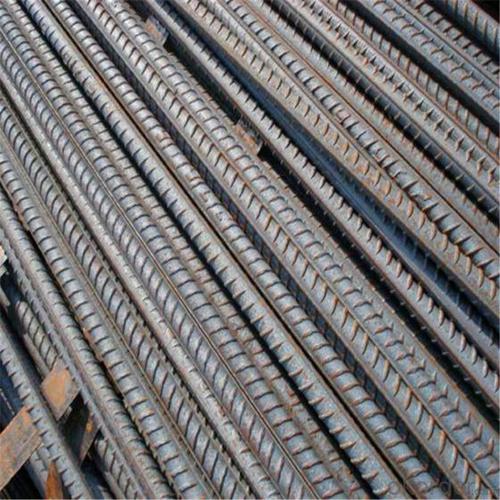

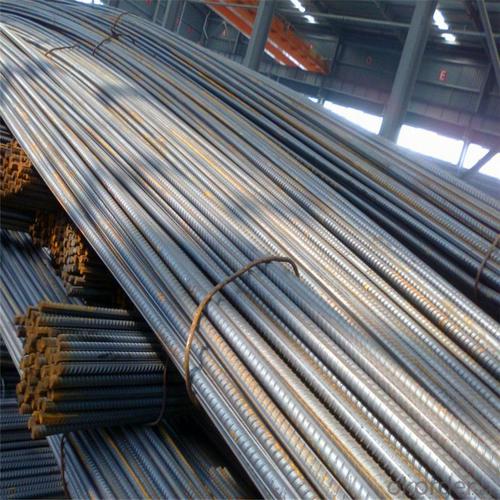

Products Show of Metallic Material Steel Iron Rods

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How can I determine the cooling water flow of square billet mold for special steel?

- The mould water quantity is calculated according to experience. The cooling water quantity of mould is calculated according to the periphery length of mould:W=2 (L+D) - QkW in mould -- cooling water quantity of mould;L - slab width, mm;D - slab thickness, mm;Qk - water flow per unit length, L/ (min = mm), for billet mold, 2.0~3.0L/ (min. Mm).

- Q: What are the different classifications of special steel?

- There are several classifications of special steel, including stainless steel, tool steel, high-speed steel, alloy steel, and carbon steel.

- Q: Can special steel be used in the production of cutting tools?

- Yes, special steel can be used in the production of cutting tools.

- Q: How does special steel perform in food processing applications?

- Special steel is widely used in food processing applications due to its unique properties and benefits. One of the key advantages of special steel in this industry is its exceptional corrosion resistance. Food processing involves exposure to various corrosive substances such as acids, alkalis, and salt solutions. Special steel, such as stainless steel, has a high chromium content that forms a protective oxide layer on its surface, preventing corrosion and ensuring the hygiene and safety of the processed food. Furthermore, special steel is highly durable and resistant to wear and tear. Food processing equipment often undergoes rigorous and repetitive operations, such as cutting, grinding, and mixing. Special steel's high strength and toughness allow it to withstand these demanding applications without compromising its performance or integrity. This durability ensures a longer lifespan for the equipment, minimizing downtime and maintenance costs. Special steel also offers excellent heat resistance, making it suitable for high-temperature food processing applications. It can withstand extreme temperatures without losing its mechanical properties, maintaining its structural integrity and preventing any contamination risks. Moreover, special steel is easy to clean and maintain, which is crucial in the food processing industry. Its smooth surface and non-porous nature prevent the accumulation of food particles, bacteria, and other contaminants, ensuring a high level of hygiene. Special steel is also resistant to chemical cleaning agents and can be easily sterilized, making it an ideal material for food processing equipment. In summary, special steel performs exceptionally well in food processing applications due to its corrosion resistance, durability, heat resistance, and ease of maintenance. Its properties contribute to the safety, efficiency, and longevity of food processing equipment, ensuring high-quality and hygienic food production.

- Q: How does special steel perform in high-pressure hydrogen environments?

- Special steel performs well in high-pressure hydrogen environments due to its high strength, corrosion resistance, and ability to withstand hydrogen embrittlement. It is designed to handle the extreme conditions associated with hydrogen, such as high temperatures and pressures, without compromising its structural integrity. Additionally, special steel alloys are often used in hydrogen storage systems, pipelines, and fuel cell components, demonstrating their reliability and effectiveness in such environments.

- Q: What are the different types of mold steel?

- There are several different types of mold steel, including P20, H13, S7, and 420 stainless steel. Each type has its own unique properties and is used for specific applications in mold making and injection molding processes. P20 is a versatile mold steel that offers good machinability and wear resistance. H13 is a hot work tool steel known for its high heat resistance and toughness. S7 is a shock-resistant mold steel suitable for applications requiring high impact resistance. 420 stainless steel is corrosion resistant and commonly used for molds that require good polishing and texturing.

- Q: What are the challenges in recycling special steel?

- One of the main challenges in recycling special steel is the complexity of its composition. Special steel often contains various alloying elements and additives that can make the recycling process more difficult. These elements need to be carefully identified and separated in order to maintain the desired properties of the recycled steel. Additionally, special steel may have undergone specific heat treatments or surface coatings, which further complicate the recycling process. Proper sorting, identification, and treatment techniques are necessary to overcome these challenges and ensure the successful recycling of special steel.

- Q: How does special steel compare to stainless steel?

- Special steel and stainless steel are both types of steel, but they differ in their composition and properties. Special steel refers to a broader category of steel that encompasses various types with specific properties tailored for specific applications, whereas stainless steel is a specific type of special steel known for its resistance to corrosion. While special steel can be customized to meet specific mechanical, thermal, or electrical requirements, stainless steel excels in providing excellent corrosion resistance, making it suitable for applications in environments with high moisture or chemical exposure. So, in summary, special steel is a broader category, while stainless steel is a specific type within that category, known for its corrosion resistance.

- Q: Can special steel be used in the food processing industry?

- Yes, special steel can be used in the food processing industry. Special steel alloys, such as stainless steel, are commonly used in food processing equipment and machinery due to their corrosion resistance, durability, and hygiene properties. These steel alloys provide a reliable and safe material for handling and processing food, making them an ideal choice for the industry.

- Q: How does special steel perform in cryogenic toughness?

- Special steel performs well in cryogenic toughness due to its unique composition and manufacturing processes. It is specifically designed to maintain its strength, hardness, and toughness even at extremely low temperatures. This makes it highly resistant to brittle fracture and ensures reliable performance in cryogenic applications, such as liquefied natural gas (LNG) storage tanks, aerospace components, and superconducting magnets.

Send your message to us

Metallic Material Steel Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords