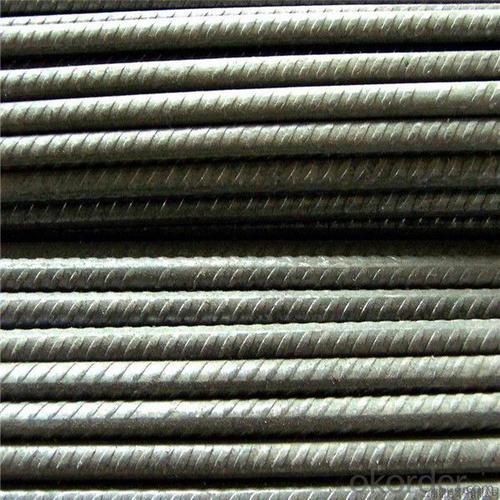

Metallic material steel rebar for construction concrete for building metal

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Epoxy-coated rebar or stainless steel rebar may be employed in these situations at greater initial expense, but

significantly lower expense over the service life of the project. Fiber-reinforced polymer rebar is now also being

used in high-corrosion environments

Most grades of steel used in rebar cannot accept welding; such as, to adjacent steel plates or as means to bind

single pieces of rebar together. However, special grades of rebar steel and welding rods make welding by expert

welders possible.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over

or covered with special plastic "mushroom" caps.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

|

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How are steel rebars protected against damage from construction equipment?

- Steel rebars are typically protected against damage from construction equipment through various measures, such as using plastic or rubber caps to cover the ends of rebars, using wooden or rubber mats to create a buffer between the equipment and the rebars, or implementing safety guidelines and protocols to ensure that equipment operators are cautious and avoid direct contact with the rebars. Additionally, rebars can also be pre-bent or pre-installed at a safe distance from the equipment's reach to minimize the risk of damage.

- Q: Can steel rebars be used in structures with extreme temperature variations?

- Structures that experience extreme temperature variations can generally utilize steel rebars. Steel possesses exceptional durability and strength due to its high melting point, making it suitable for various construction applications. However, there are several factors to consider when employing steel rebars in such structures. To begin with, steel exhibits thermal expansion, meaning it expands and contracts as temperatures fluctuate. If not properly addressed, this expansion and contraction can potentially stress and strain the structure. Engineers and architects counteract this issue by implementing design techniques such as incorporating expansion joints or allowing for thermal movement. These measures accommodate the steel's thermal expansion and prevent damage. Additionally, extreme temperature variations can impact the mechanical properties of steel. Exposure to high temperatures can cause steel to lose its strength and stiffness, compromising the structural integrity. Conversely, low temperatures can make the steel brittle, increasing the likelihood of cracks or fractures. Therefore, it is crucial to select steel rebars of the appropriate grade and quality, specifically designed to withstand the expected temperature variations. Furthermore, the type and purpose of the structure should be taken into consideration. For example, in structures where extreme temperature variations are anticipated, such as bridges or buildings in regions with hot summers and cold winters, thermal insulation or other measures should be incorporated into the design. These measures prevent excessive heat transfer or the accumulation of thermal stress. In conclusion, steel rebars can be employed in structures experiencing extreme temperature variations, but careful considerations must be made. By accounting for thermal expansion, selecting suitable steel grades, and incorporating design techniques to accommodate temperature changes, the structural integrity and performance can be maintained. This ensures the safety and longevity of the construction.

- Q: Can steel rebars be used in structures with high aesthetic requirements?

- Yes, steel rebars can be used in structures with high aesthetic requirements. While steel rebars are primarily used for their strength and durability, they can also be designed and incorporated in a way that meets aesthetic requirements. Rebars can be shaped, bent, or painted to match the desired aesthetic of the structure. Additionally, they can be hidden within the structure or covered by other materials to maintain a clean and visually appealing appearance. With careful planning and design, steel rebars can be successfully used in structures with high aesthetic requirements without compromising their functionality or visual appeal.

- Q: How do steel rebars perform in extreme temperature conditions?

- Steel rebars perform well in extreme temperature conditions due to their high thermal conductivity and low coefficient of thermal expansion. This means that they can efficiently transfer heat and resist deformation caused by temperature changes. In extremely high temperatures, steel rebars retain their strength and structural integrity. They have a high melting point and maintain their properties even in intense fire situations. This makes them ideal for reinforcing structures such as buildings, bridges, and tunnels, where fire resistance is crucial. In extremely low temperatures, steel rebars also perform admirably. Unlike some other materials, steel does not become brittle and lose its strength in cold conditions. This makes it suitable for use in cold climates and regions with frequent freeze-thaw cycles. Furthermore, steel rebars have excellent durability and can withstand extreme temperature fluctuations without significant degradation. They do not expand or contract excessively, which helps to maintain the stability and longevity of reinforced structures. However, it's important to note that extreme temperatures can still have some impact on steel rebars. In very high temperatures, steel may experience some thermal expansion, which can cause minor stresses in the surrounding concrete. Similarly, in very low temperatures, some contraction may occur, but these effects are usually minimal and well within acceptable limits. Overall, steel rebars are a reliable choice for reinforcing structures in extreme temperature conditions, as they offer excellent strength, durability, and fire resistance.

- Q: Are steel rebars susceptible to fatigue failure?

- Yes, steel rebars are susceptible to fatigue failure. Fatigue failure occurs when a material undergoes repeated cyclic loading, causing cracks to initiate and propagate, leading to eventual failure. Steel rebars, which are commonly used in construction to reinforce concrete structures, can experience fatigue failure if they are subjected to repeated loading and unloading cycles over an extended period. To prevent fatigue failure, proper design considerations, such as adequate reinforcement, avoidance of high stress concentrations, and regular maintenance, should be implemented.

- Q: How do steel rebars provide flexibility to concrete structures?

- Steel rebars provide flexibility to concrete structures by acting as reinforcement. When concrete is poured around the rebars, they provide tensile strength to the structure, allowing it to withstand external forces and prevent cracking or collapsing. The rebars help distribute the load evenly throughout the concrete, making the structure more flexible and resistant to bending or breaking under pressure.

- Q: Can steel rebars be used in the construction of residential communities?

- Yes, steel rebars can be used in the construction of residential communities. Steel rebars are commonly used in the construction industry for reinforcing concrete structures, including residential buildings. They provide strength and durability to the concrete, improving its load-bearing capacity and resistance to cracks and other forms of structural damage. Steel rebars are often used in residential construction to reinforce foundation footings, walls, columns, and beams. They help to ensure the structural integrity of the building, making it safer and longer-lasting. Additionally, steel rebars can be easily customized and shaped to fit specific design requirements, allowing for flexibility in construction. Overall, the use of steel rebars in residential communities is a common and widely accepted practice in the construction industry.

- Q: Can steel rebars be used in heritage building restoration?

- Yes, steel rebars can be used in heritage building restoration. Steel rebars provide structural reinforcement to the building, ensuring its stability and longevity. However, it is important to seek expert advice and follow specific guidelines to ensure the preservation of the building's historical integrity during the restoration process.

- Q: What is the process of welding steel rebars together?

- The process of welding steel rebars together involves first cleaning the rebars to remove any rust, paint, or contaminants. Then, the rebars are positioned and clamped into place using jigs or fixtures. A welding machine is used to generate an electric arc between the rebars, which melts the metal at the joint. A filler metal, usually in the form of welding rods, is added to the molten pool to reinforce the weld. The arc heat fuses the rebars and filler metal together, forming a strong bond. Finally, the welded rebars are allowed to cool down, and any excess weld material is cleaned off to achieve a smooth finish.

- Q: What is the role of steel rebars in ensuring occupant safety?

- Steel rebars play a crucial role in ensuring occupant safety in various structures, particularly in buildings and infrastructure. These reinforced steel bars are commonly used in concrete construction to enhance the strength and durability of the structure, ultimately safeguarding the individuals residing or working within them. The primary function of steel rebars is to provide structural reinforcement to concrete elements, such as columns, beams, and slabs. By incorporating rebars into the concrete, the overall load-bearing capacity of the structure is significantly increased, allowing it to withstand various external forces and loads. This greatly reduces the risk of collapse or structural failure, which could potentially harm the occupants. During seismic events, such as earthquakes, steel rebars play a critical role in dissipating and distributing the energy exerted on the structure. The ductility and tensile strength of steel allow it to absorb and distribute the seismic forces, reducing the chances of a sudden structural failure. This ensures that the occupants are protected from the potential hazards associated with seismic activity. Moreover, steel rebars enhance the fire resistance of concrete structures. While concrete itself possesses good fire-resistant properties, the inclusion of steel rebars further reinforces this resistance. Steel has a high melting point, and its thermal conductivity is relatively low compared to other materials. This means that steel rebars can withstand high temperatures for an extended period, ensuring the structural integrity of the building during a fire and providing occupants with a safe evacuation route. In addition to their structural benefits, steel rebars also contribute to the long-term durability and maintenance of the structure. By preventing cracks and minimizing the effects of corrosion, rebars help maintain the structural integrity of the concrete over time. This ensures that the occupants are not exposed to potential hazards caused by the deterioration of the structure. Overall, the role of steel rebars in ensuring occupant safety is indispensable. They provide structural reinforcement, increase load-bearing capacity, enhance fire resistance, and contribute to the long-term durability of a structure. By incorporating steel rebars into concrete construction, the risk of collapse, structural failure, and other potential hazards is significantly reduced, ultimately providing a safe environment for the occupants.

Send your message to us

Metallic material steel rebar for construction concrete for building metal

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords