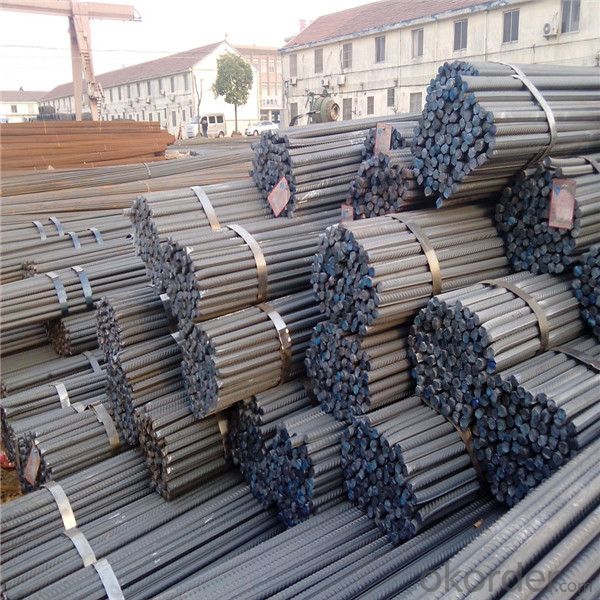

Iron rods for construction in stock for sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel rebar is bars of steel commonly used in construction, especially for reinforcing concrete structures such as

driveways, foundations, walls, and columns. These bars come in different sizes and strength grades, and can be

smooth or may include deformations that provide greater adhesion for concrete poured over the bars. When used

in poured concrete, the bars are typically placed in a grid pattern, the concrete poured over them, and then readjusted

to maintain the proper shape while the concrete sets. Steel rebar can be purchased from a number of manufacturers

and is often found at construction retailers or large hardware stores

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: Can steel rebars be used in structures exposed to extreme weather conditions?

- Yes, steel rebars can be used in structures exposed to extreme weather conditions. Steel rebars are known for their strength, durability, and resistance to harsh environmental conditions, including extreme weather such as high temperatures, heavy rain, and strong winds. They provide structural stability and can withstand the impact of severe weather conditions, making them a suitable choice for such structures. Additionally, proper corrosion protection measures, such as epoxy coating or galvanization, can further enhance their resilience in challenging weather environments.

- Q: What is the impact of steel rebars on the overall durability of a structure?

- Steel rebars have a significant impact on the overall durability of a structure. These reinforced bars enhance the strength and load-bearing capacity of concrete, making it more resistant to various forces such as tension, compression, and bending. By preventing cracking and improving structural stability, steel rebars greatly enhance the longevity and durability of a structure, ensuring it can withstand the test of time and various environmental conditions.

- Q: What are the different types of steel rebars available for different applications?

- There are several different types of steel rebars available for various applications. Some of the most commonly used types include: 1. Mild Steel Rebars: These are the most common type of rebars used in construction projects. They have a low carbon content and are relatively inexpensive. Mild steel rebars are suitable for general construction purposes and are used in residential buildings, bridges, and small to medium-sized structures. 2. High-strength Reinforcement Bars (HSRB): These rebars have a higher tensile strength compared to mild steel rebars. They are commonly used in high-rise buildings, large infrastructure projects, and heavy-duty structures where greater strength is required. HSRB rebars are often made from alloys such as carbon, manganese, or silicon to enhance their strength. 3. Epoxy-Coated Rebars: These rebars are coated with epoxy resin to protect them from corrosion. Epoxy-coated rebars are commonly used in marine structures, parking garages, and areas with high humidity or exposure to moisture. The epoxy coating acts as a barrier, preventing the steel from coming into contact with corrosive elements, thus extending the lifespan of the rebar. 4. Stainless Steel Rebars: Unlike mild steel rebars, stainless steel rebars contain a significant amount of chromium, which provides excellent resistance to corrosion. These rebars are often utilized in highly corrosive environments such as coastal areas, chemical plants, and wastewater treatment facilities. Stainless steel rebars are also used in structures that require a high aesthetic appeal, such as architectural buildings and monuments. 5. Galvanized Rebars: Galvanized rebars are coated with zinc to protect them from corrosion. The zinc coating acts as a sacrificial layer, corroding itself before the underlying steel is affected. These rebars are commonly used in areas with moderate corrosion risks, such as concrete structures exposed to deicing salts or in coastal regions. 6. Carbon Fiber Reinforced Polymer (CFRP) Rebars: CFRP rebars are made of carbon fibers embedded in a polymer matrix. They are lightweight, corrosion-resistant, and have high tensile strength. CFRP rebars are commonly used in retrofitting existing structures, as they provide excellent strength and durability without adding significant weight. The choice of steel rebar depends on the specific application, environmental conditions, and structural requirements. It is essential to consult with structural engineers and adhere to local building codes and standards to ensure the appropriate type of rebar is selected for each project.

- Q: What are the guidelines for proper bending of steel rebars on construction sites?

- The guidelines for proper bending of steel rebars on construction sites typically include the following: 1. Use the correct tools: Ensure that the bending tools, such as rebar benders or hydraulic machines, are suitable for the specific diameter and grade of the rebar being bent. 2. Follow the bending specifications: Adhere to the bending specifications mentioned in the construction drawings or project plans. These specifications outline the required bending angles, radii, and bend locations for each rebar. 3. Handle rebar with care: Ensure proper handling and storage of rebars to prevent damage or deformations that may affect the bending process. 4. Measure accurately: Take precise measurements before bending to ensure the rebars are cut to the correct length and the bends are made at the designated locations. 5. Use proper bending techniques: Employ appropriate bending techniques, such as using gradual bends rather than sharp angles, to prevent stress concentrations and minimize the risk of rebar failure. 6. Inspect bent rebars: Regularly inspect the bent rebars for any cracks, deformations, or defects that may compromise their structural integrity. Replace any damaged rebars promptly. 7. Follow safety precautions: Always prioritize safety by wearing appropriate protective equipment, such as gloves and safety glasses, and following established safety protocols while bending rebars. It is important to note that guidelines may vary depending on local regulations, project requirements, and specific rebar types. Therefore, it is essential to consult with relevant industry standards, project specifications, and experienced professionals to ensure compliance and achieve proper bending of steel rebars on construction sites.

- Q: What are the common problems associated with steel rebars in construction?

- Steel rebars in construction can pose several common problems. One of the primary concerns is corrosion, as moisture and oxygen can cause rusting, particularly in humid or coastal areas. This rusting weakens the rebars and compromises the structure's integrity. Improper installation is another issue. If rebars are not correctly positioned or adequately secured, they fail to provide the necessary reinforcement and support, leading to safety hazards and structural failures. Concerns also arise regarding the size and spacing of rebars. Inadequate distribution of loads or poor resistance to bending and cracking can occur if the rebars are too small or spaced too far apart. Conversely, if the rebars are too large or closely placed, construction costs increase, and the concrete mix becomes difficult to work with. Poor bonding between the rebar and the concrete poses another challenge. Inadequate contact or bonding between these materials compromises the structure's integrity and reduces the load-bearing capacity of the reinforced concrete. Lastly, the quality of the steel rebars themselves can be problematic. Defects such as impurities or inconsistencies in composition weaken the reinforcement and compromise the overall strength of the structure. To address these issues, it is crucial to use high-quality rebars, adhere to proper installation techniques, and ensure maintenance and protection against corrosion. Regular inspections and testing aid in identifying problems and ensuring the longevity and safety of the reinforced concrete structure.

- Q: Are there any disadvantages of using steel rebars?

- Yes, there are some disadvantages of using steel rebars. 1. Corrosion: One of the main disadvantages of steel rebars is their susceptibility to corrosion. When exposed to moisture and oxygen, steel rebars can rust over time, which weakens their structural integrity. This issue can be particularly problematic in coastal areas with high humidity levels or in structures exposed to harsh weather conditions. 2. Weight: Steel rebars are relatively heavy compared to other alternatives like fiberglass or carbon fiber reinforced polymers. This can pose challenges during transportation and installation, especially in large-scale construction projects where heavy machinery is required to move and position the rebars. 3. Cost: Steel rebars tend to be more expensive compared to other reinforcement materials, which can increase the overall cost of a construction project. Additionally, the price of steel is subject to market fluctuations, making it difficult to predict the exact budget for reinforcement materials. 4. Conductivity: Steel rebars are highly conductive to heat and electricity. This can be a disadvantage in structures that require insulation or in areas with high electrical conductivity requirements. In such cases, additional insulation or grounding measures may need to be implemented, adding extra complexity and cost to the construction process. 5. Environmental impact: Steel production is energy-intensive and contributes to greenhouse gas emissions. The extraction and processing of iron ore to manufacture steel rebars can have a significant environmental impact, including deforestation, habitat destruction, and air and water pollution. Despite these disadvantages, steel rebars remain widely used in construction due to their high tensile strength, durability, and proven track record in providing structural support. Additionally, advancements in corrosion-resistant coatings and the development of alternative reinforcement materials are continuously being explored to mitigate these drawbacks.

- Q: What are the different types of steel rebars used in tunneling?

- The different types of steel rebars commonly used in tunneling include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. These rebars are chosen based on their specific properties and characteristics, such as strength, corrosion resistance, and durability, to ensure the tunnel structure's integrity and longevity.

- Q: What is the process of threading steel rebars?

- Threading steel rebars involves creating threads on the ends of the rebars to allow for easy and secure connection with other rebars or structural elements. This is typically done using a machine called a rebar threading machine. The first step is to cut the rebars to the desired length and clean the ends to remove any dirt, rust, or debris that could interfere with the threading process. This ensures a smooth and accurate threading operation. Once the rebars are prepared, the rebar threading machine is set up. It consists of a spindle that rotates at a high speed, along with a threading die positioned on the spindle. The threading die has grooves and ridges designed to cut threads into the rebars. To thread a rebar, one end is inserted into the threading machine while the other end is held firmly in place. The machine is then started, and the spindle rotates to cut into the rebar's surface, creating threads by removing small amounts of material. The machine is operated until the desired length of threads is achieved, which can vary depending on project requirements and the type of connection being made. It is crucial to ensure accurate and consistent cutting of the threads to maintain the structural integrity of the rebar connections. After the threading process is complete, the threaded rebars are inspected to ensure clean and defect-free threads that meet the required standards. They are then ready for use in construction projects, where they can be connected to other rebars or structural elements using various methods such as couplers or nuts. In conclusion, threading steel rebars involves cutting and cleaning the rebars, setting up a rebar threading machine, inserting the rebars, and using a threading die to create threads. This process ensures easy and secure connection of rebars in construction projects, providing strength and stability to the structures they are used in.

- Q: What is the effect of steel rebars on the seismic performance of a structure?

- Steel rebars, also referred to as reinforcing bars, play a crucial role in enhancing the seismic performance of structures by improving their overall strength and ductility. When structures are subjected to seismic forces, they undergo intense shaking and vibrations. The inclusion of steel rebars significantly enhances the strength and ductility of the structure, enabling it to withstand and absorb the energy released during an earthquake. The primary effect of steel rebars is their capacity to augment the tensile strength of concrete. Concrete is strong when compressed but weak when subjected to tension. By embedding steel rebars within the concrete, the composite material becomes capable of resisting tensile forces that may occur during an earthquake. This prevents the concrete from cracking or fracturing, ensuring the structure remains intact and functional. Furthermore, steel rebars act as a reinforcement mechanism by distributing the seismic load uniformly across the entire structure. During an earthquake, the shaking motion is dispersed throughout the building, minimizing stress concentration in specific areas. This redistribution of forces helps to maintain the overall stability of the structure, preventing localized failure and collapse. In addition, the presence of steel rebars enhances the ductility of the structure. Ductility refers to the material's ability to deform under stress without breaking. When seismic forces act on a building, the steel rebars provide flexibility and allow for controlled deformation. This plastic behavior aids in dissipating the energy generated during an earthquake, reducing the impact on the structure and minimizing potential damage. Moreover, steel rebars also contribute to the overall stiffness of the structure. By reinforcing concrete components such as columns, beams, and walls, the rigidity of the entire system is increased. This stiffness helps to limit displacement and deformation of the structure, mitigating the risk of structural failure and ensuring the safety of occupants during a seismic event. To summarize, the presence of steel rebars in a structure significantly improves its seismic performance by enhancing concrete's tensile strength, distributing seismic load, improving ductility, and increasing overall stiffness. These effects collectively enhance the structure's ability to resist and withstand the forces generated during an earthquake, ensuring the integrity of the structure and the safety of its occupants.

- Q: How are steel rebars protected during concrete pouring?

- Steel rebars are protected during concrete pouring by applying a layer of corrosion-resistant coating or by using epoxy-coated rebars. Additionally, rebars are often placed at a specific depth within the concrete to ensure adequate cover and protection against moisture and corrosive elements.

Send your message to us

Iron rods for construction in stock for sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords