IPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

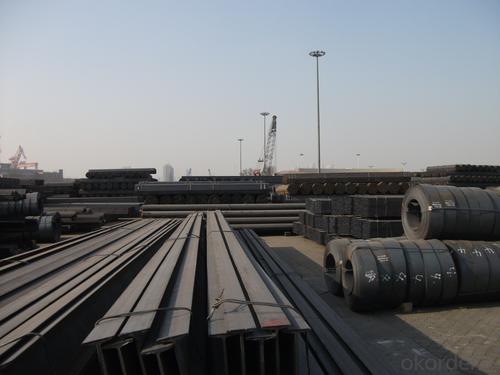

Product Description:

IPE Beam Details:

| Minimum Order Quantity: | 10MT | Unit: | m.t. | Loading Port: | Tianjin Port, China |

| Supply Ability: | 10000MT | Payment Terms: | TT or LC |

Product Description:

Specifications of IPE Beam

1. Invoicing on theoretical weight or actual weight as customer request

2. Standard: EN10025, GB Standard, ASTM

3. Grade: Q235B, Q345B, SS400, ASTM A36, S235JR, S275JR

4. Length: 5.8M, 6M, 9M, 12M as following table

5. Sizes: 80mm-270mm

Dimensions(mm) | |||||

h | b | s | t | Mass Kg/m | |

IPE80 | 80 | 46 | 3.80 | 5.20 | 6.00 |

IPE100 | 100 | 55 | 4.10 | 5.70 | 8.10 |

IPE120 | 120 | 64 | 4.80 | 6.30 | 10.40 |

IPE140 | 140 | 73 | 4.70 | 6.90 | 12.90 |

IPE160 | 160 | 82 | 5.00 | 7.40 | 15.80 |

IPE180 | 180 | 91 | 5.30 | 8.00 | 18.80 |

IPE200 | 200 | 100 | 5.60 | 8.50 | 22.40 |

IPE220 | 220 | 110 | 5.90 | 9.20 | 26.20 |

IPE240 | 240 | 120 | 6.20 | 9.80 | 30.70 |

IPE270 | 270 | 135 | 6.60 | 10.20 | 36.10 |

Appications of IPE Beam

1. Supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers, etc

2. Prefabricated structure

3. Medium scale bridges

4. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Package & Delivery of IPE Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks: Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

4. Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

5. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

6. Delivery of IPE Beam: 30 days after getting L/C Original at sight or T/T in advance

Production flow of IPE Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: What are the different types of steel finishes available for I-beams in renovations?

- There are several types of steel finishes available for I-beams in renovations, each with its own unique characteristics and aesthetic appeal. Some of the commonly used finishes include: 1. Mill Finish: This is the most basic finish and is the result of the steel being hot rolled in the mill without any further treatment or coating. It has a dark gray, slightly rough surface and is typically used in industrial or structural applications where aesthetics are not a major concern. 2. Painted Finish: I-beams can be painted with a variety of coatings to provide protection against corrosion and enhance their appearance. Paint finishes can range from basic primers to more durable and weather-resistant options, such as epoxy or polyurethane coatings. Painted finishes can be customized to match the overall color scheme of the renovation project. 3. Galvanized Finish: Galvanizing is a popular finishing method that involves coating the steel with a layer of zinc to protect it from rust and corrosion. Galvanized I-beams have a distinctive silver-gray appearance and are commonly used in outdoor or high-moisture environments, such as bridges, balconies, or coastal construction projects. 4. Powder Coated Finish: Powder coating is a dry finishing process that involves applying a powdered paint onto the surface of the steel. The powder is then heated and fused into a smooth, durable finish. Powder coating offers a wide range of color options, excellent corrosion resistance, and a uniform appearance, making it a popular choice for architectural and decorative applications. 5. Stainless Steel Finish: Stainless steel I-beams are often used in high-end renovations due to their superior corrosion resistance and modern, sleek appearance. The steel is typically polished to achieve a reflective surface, giving it a shiny and luxurious finish. Stainless steel finishes are commonly found in upscale residential and commercial projects, such as restaurants, hotels, and modern homes. It is important to consider the specific requirements of the renovation project, including the desired level of corrosion resistance, aesthetic preferences, and budget constraints, when choosing the appropriate steel finish for I-beams. Consulting with a structural engineer or a steel supplier can help ensure the best choice for your specific needs.

- Q: Can steel I-beams be used for historical preservation projects?

- Yes, steel I-beams can be used for historical preservation projects. They provide structural support and can help reinforce historical structures while maintaining their original aesthetics. Additionally, steel I-beams offer durability and longevity, ensuring the preservation of historical buildings for future generations.

- Q: How do steel I-beams compare to other types of structural beams?

- Considered by many to be one of the most versatile and efficient structural beams, steel I-beams possess a multitude of advantages when compared to wooden or concrete beams. First and foremost, steel I-beams boast an exceptional strength-to-weight ratio. This characteristic allows them to bear heavy loads while remaining relatively lightweight. Consequently, they are an ideal choice for large-scale construction projects, such as bridges or skyscrapers, where minimizing the weight of the structure is crucial without compromising its strength. Secondly, steel I-beams exhibit remarkable durability and structural integrity. Steel, as a highly resilient material, can withstand extreme weather conditions including earthquakes, high winds, and heavy snow loads. Moreover, it boasts an extended lifespan and requires minimal maintenance, making it a cost-effective choice in the long run. Another advantage of steel I-beams lies in their flexibility and adaptability. They can be easily fabricated and customized to meet specific design requirements. Steel can be cut, shaped, and welded into various lengths and shapes, offering greater design flexibility. Consequently, it becomes possible to create intricate structures and achieve unique architectural designs. Additionally, steel I-beams provide superior fire resistance compared to their counterparts. Being non-combustible, steel does not contribute to the spread of fire. This feature makes it a safer option for buildings and structures, particularly in areas with stringent fire safety regulations. Lastly, steel I-beams are environmentally friendly. Steel is a recyclable material, allowing it to be reused or repurposed at the end of its life cycle. By recycling steel, natural resources can be conserved, and carbon emissions associated with the production of new steel can be reduced. To conclude, steel I-beams offer numerous advantages over other types of structural beams. These advantages include a high strength-to-weight ratio, durability, flexibility, fire resistance, and environmental sustainability. Given these qualities, it is no surprise that steel I-beams have become a popular choice in the construction industry for a wide range of applications.

- Q: How do you anchor steel I-beams to the foundation?

- Steel I-beams can be anchored to the foundation using various methods, including bolting or welding. The chosen method typically depends on the specific requirements of the project and the engineer's recommendations. Bolted connections involve drilling holes in the foundation and securing the beams with anchor bolts. On the other hand, welding involves melting the steel of the beam with the foundation, creating a strong and permanent connection. Both methods ensure the I-beams are securely attached to the foundation, providing stability and support to the structure.

- Q: How does deflection affect steel I-beams?

- The bending or displacement that occurs in a structural element, like a steel I-beam, when it is subjected to a load is referred to as deflection. In the case of steel I-beams, deflection can have both positive and negative effects on their performance. On one side, excessive deflection can be harmful to the structural integrity of steel I-beams. When deflection surpasses the allowable limits, it can result in structural failure, compromising the safety and stability of a building or structure. Additionally, excessive deflection can lead to aesthetic problems, such as sagging or uneven floors, which may not be desirable in architectural designs. On the other hand, deflection can also be advantageous in certain situations. It permits the steel I-beam to efficiently absorb and distribute loads, reducing stress concentrations and preventing localized failures. Deflection enables the I-beam to adapt to varying loads and external forces, allowing it to flex and deform without reaching its ultimate strength limit. This characteristic is particularly valuable in applications where the I-beam is exposed to dynamic loads, like in bridges or high-rise buildings. To ensure the proper performance of steel I-beams, engineers and designers carefully calculate and control the limits of deflection based on various factors, such as the type and magnitude of the load, the length of the span, and the properties of the material. These calculations aid in determining the appropriate size and shape of the I-beam, as well as the necessary supports and connections. In conclusion, deflection plays a vital role in the behavior of steel I-beams. While excessive deflection can result in structural issues, controlled deflection allows the I-beam to adapt to loads and distribute stress more effectively, enhancing its overall performance and reliability.

- Q: What are the considerations for acoustical isolation when using steel I-beams?

- There are several crucial factors to consider when it comes to acoustical isolation with steel I-beams. To begin with, the design and installation of the steel I-beams must prioritize proper decoupling from the surrounding structure. This means that direct contact with walls, floors, or other structural elements that could transmit sound vibrations should be avoided. Achieving this decoupling and preventing sound transmission through the beams can be accomplished by using resilient materials like rubber pads or neoprene isolators. Additionally, the acoustical isolation can be influenced by the size and shape of the steel I-beams. Generally, thicker and wider beams possess better sound insulation properties compared to smaller or lighter ones. The higher mass and stiffness of larger beams aid in reducing the transmission of sound waves. The overall structural design of the building should also be taken into consideration. It is crucial to properly integrate the steel I-beams into the overall acoustic design of the space. This involves considering factors such as the placement of walls, windows, and doors, as well as utilizing other soundproofing materials like acoustic panels or insulation. Furthermore, the type of flooring system used in conjunction with the steel I-beams can impact acoustical isolation. For instance, a floating floor system, which incorporates a layer of resilient material between the floor and the beams, can help minimize sound transmission. Lastly, it is essential to consider the specific acoustical isolation requirements of the space. Different applications, such as residential, commercial, or industrial, may have varying noise control needs. Understanding these requirements and collaborating with acoustical consultants or engineers can guarantee that the steel I-beams are appropriately designed and installed to achieve the desired level of acoustical isolation.

- Q: What are the different types of steel I-beams?

- There exists a variety of steel I-beams, each designed to fulfill specific structural needs and requirements. Some of the most prevalent types include: 1. W-Beam: The most commonly utilized I-beam, it features a wide flange section resembling the letter "W". It offers exceptional support and load-bearing capabilities, allowing for a wide range of applications. 2. S-Beam: Also known as American Standard Beams, S-beams possess a narrower flange section resembling the letter "S". They find common usage in residential construction and light to medium-duty applications. 3. HP-Beam: HP-beams, or H-piles, showcase a wider flange section and are predominantly employed in deep foundation applications, such as supporting large structures or bridges. They exhibit excellent load-bearing capacity and resistance to lateral forces. 4. M-Beam: M-beams, or miscellaneous beams, typically cater to smaller-scale applications or situations necessitating specific load requirements. They come in various sizes and are frequently employed in the construction industry for framing, support structures, and similar applications. 5. L-Beam: L-beams, also known as angle beams, consist of two legs forming an L-shape. Primarily used for structural purposes, they provide support for columns, beams, or act as braces in construction projects. 6. C-Beam: C-beams, or channel beams, feature a C-shaped cross-section and are commonly utilized for structural purposes, such as framing, support, or as tracks for sliding doors or windows. These examples represent only a fraction of the diverse steel I-beams available. It is crucial to select the appropriate type based on project-specific requirements, including load-bearing capacity, span, and structural needs. Consulting with a structural engineer or steel supplier can aid in determining the most suitable I-beam type for a particular application.

- Q: Are there any limitations on the length of steel I-beams?

- The length of steel I-beams is subject to limitations. These limitations stem from the manufacturing process, transportation restrictions, and the structural needs of the specific application. When it comes to manufacturing, the length of steel I-beams is primarily restricted by the size of the equipment employed in their production. Steel mills utilize machinery designed for shaping steel into different forms, including I-beams. These machines have their own maximum length limitations. Transportation constraints also contribute to the limitation of steel I-beam lengths. Longer beams may pose difficulties during transportation due to weight restrictions, road or bridge limitations, or logistical obstacles. Compliance with local regulations and transportation capabilities necessitates consideration of the beams' size and weight. Additionally, the structural requirements of the application influence the length of steel I-beams. Longer beams may require additional support, such as intermediate columns or bracing, to ensure structural stability. The beam's strength and rigidity must be evaluated in relation to the span it is intended to cover. In conclusion, although there are no universal fixed limits on the length of steel I-beams, their dimensions are generally determined by the capabilities of the manufacturing process, transportation restrictions, and the structural demands of the particular application.

- Q: Can steel I-beams be used in the construction of amusement parks and entertainment venues?

- Certainly, amusement parks and entertainment venues can utilize steel I-beams in their construction. The construction industry commonly relies on steel I-beams due to their strength, durability, and versatility. These beams are highly effective in providing support and carrying heavy loads, making them ideal for structures like roller coasters, observation towers, and large entertainment stages. Amusement park construction benefits greatly from the use of steel I-beams. Firstly, their strength-to-weight ratio is impressive, allowing for designs that can endure substantial loads while minimizing the need for excessive materials. This is particularly crucial in amusement park structures, where safety and structural integrity are paramount. Additionally, steel I-beams can be fabricated to precise specifications, enabling customized designs that suit the unique needs and architectural requirements of amusement parks and entertainment venues. Moreover, steel I-beams possess remarkable resistance to environmental factors such as corrosion, fire, and pests. This makes them a dependable choice for amusement parks, which often face diverse weather conditions and high levels of foot traffic. Steel I-beams can withstand these elements and maintain their structural integrity over time, guaranteeing the longevity and safety of the amusement park or entertainment venue. In conclusion, steel I-beams represent an outstanding option for constructing amusement parks and entertainment venues. They deliver the necessary strength, durability, and versatility required for such structures, offering a secure and dependable framework for visitors to enjoy.

- Q: Can steel I-beams be used for modular bridges or flyovers?

- Yes, steel I-beams can be used for modular bridges or flyovers. Steel I-beams are commonly used in the construction industry due to their strength, durability, and versatility. They are capable of bearing heavy loads and providing stability, which makes them suitable for various applications, including bridge construction. Modular bridges or flyovers are often designed to be prefabricated in sections and then assembled on-site, allowing for a faster and more efficient construction process. Steel I-beams are well-suited for modular construction as they can be easily fabricated to the required specifications and transported to the site for assembly. The use of steel I-beams in modular bridge or flyover construction offers several advantages. Firstly, steel is a lightweight material compared to alternatives like concrete, making it easier and more cost-effective to transport and assemble. Additionally, steel I-beams can be designed to withstand different types of loads, such as the weight of vehicles or large crowds, ensuring the structural integrity and safety of the bridge or flyover. Furthermore, steel I-beams provide flexibility in terms of design and adaptability to different site conditions. They can be easily modified or extended if necessary, allowing for future expansion or modifications. Steel also possesses excellent resistance to corrosion, which is crucial for structures exposed to outdoor elements and harsh environmental conditions. In conclusion, steel I-beams are a suitable choice for modular bridges or flyovers due to their strength, durability, versatility, and ease of assembly. Their use ensures the construction of safe and reliable structures that can withstand heavy loads and adapt to changing requirements.

Send your message to us

IPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords