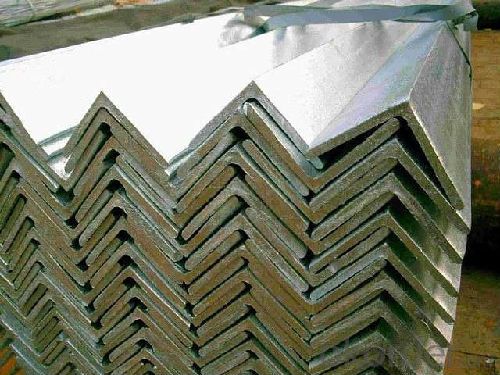

Chinese Standard Hot Rolled Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Chinese Standard Hot Rolled Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Chinese Standard Hot Rolled Angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Chinese Standard Hot Rolled Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What does the beam size "H500*250*8*10*10" mean?

- For example, H steel is divided into three types: wide flange H section steel (HK), narrow flange H (HZ) and H steel pile (HU)H steel beam in 300*150*6.5*9: steel structure, height 300mm, width 150mm, web thickness 6.5mm, wing plate thickness 9mm300*180*6*8:H steel beam, height 300mm, width 180mm, web thickness 6mm, wing plate thickness 8mm

- Q: What are the different types of load tests conducted on Steel I-Beams?

- There are several types of load tests conducted on Steel I-Beams, including ultimate strength tests, yield strength tests, and fatigue tests. Ultimate strength tests determine the maximum load a beam can withstand before failure, while yield strength tests measure the load at which the beam begins to deform permanently. Fatigue tests subject the beam to repeated loading and unloading cycles to assess its resistance to fatigue failure over time.

- Q: Elevator room in the cement blocks is what to do for?

- Is used to work beam bearing all the weight of the elevator traction machine.

- Q: Is h160*100*6 steel made of light I-beam?

- H type I-beam is also called wide flange I-beam, HW, HM, HN originated from European standards, HEB is the German standard of I-beam, of which HW, HN I-beam has been widely used in our country and production. HEA HEB HEM will be seen on many German designs and is hard to buy on the domestic market. In the domestic steel structure engineering, if the quantity is few, then may use the specification steel plate to carry on the welding splicing. In the case of large quantities, it is usually considered to use mechanical properties comparable to those of HW and HN steel.

- Q: Are steel I-beams suitable for supporting rooftop swimming pools?

- No, steel I-beams are not suitable for supporting rooftop swimming pools. The weight of the pool, combined with the water and the people in it, would put too much stress on the beams, potentially leading to structural failure.

- Q: Can steel I-beams be used in stadium construction?

- Yes, steel I-beams can be used in stadium construction. In fact, steel I-beams are commonly used in the construction of stadiums due to their strength and versatility. They provide structural support and can withstand heavy loads, making them ideal for large-scale projects like stadiums. Additionally, steel I-beams can be customized and fabricated to meet the specific design and architectural requirements of the stadium, ensuring a safe and efficient construction process.

- Q: What are the different types of steel I-beam support systems?

- In construction and structural engineering, there are various steel I-beam support systems commonly utilized. Here are some of the most prevalent types: 1. Rolled I-Beams: These I-beam support systems serve as the fundamental and widely employed type. They are produced by rolling steel plates into the shape of an I-beam, featuring different dimensions and load-bearing capacities. 2. Welded I-Beams: To create a larger and sturdier beam, these support systems are crafted by welding together two or more rolled I-beams. This technique facilitates the customization of I-beams to meet specific load-bearing requirements. 3. Composite I-Beams: By combining different materials, such as steel and concrete, composite I-beams are produced. This fusion of materials enhances the overall load-bearing capacity and structural integrity of the I-beam. 4. Box Girders: While resembling I-beams in shape, box girders possess a rectangular or box-like cross-section. They are commonly employed when greater load-bearing capacities and longer spans are necessary. Box girders can be created using steel plates or by welding multiple sections together. 5. Tapered I-Beams: Tapered I-beams have a varying depth along their length, enabling more efficient load distribution and weight reduction. These support systems find application in structures with complex or irregular load requirements. 6. Light-gauge steel I-beams: Light-gauge steel I-beams are fashioned from thinner steel plates and are commonly used in residential construction and smaller-scale projects. They are lighter and more manageable but have lower load-bearing capacities compared to heavier-gauge I-beams. These examples represent only a fraction of the diverse steel I-beam support systems available. The selection of a suitable type depends on factors like specific load requirements, span length, and overall structural design of the building or project. Consulting a structural engineer or construction professional is crucial to determine the most appropriate I-beam support system for a particular application.

- Q: What are the potential risks of using steel I-beams in construction?

- Using steel I-beams in construction comes with various potential risks that need to be considered: 1. The issue of corrosion arises as steel is prone to rust and corrosion, especially in environments with high moisture or exposure to chemicals. Inadequate protection or maintenance of the I-beams can lead to gradual weakening and compromise the structural integrity of the building. 2. Fire resistance is another concern. Although steel is a strong material, it can rapidly lose its structural integrity when exposed to high temperatures. In the event of a fire, the steel I-beams may distort or collapse, resulting in possible structural failure. To mitigate this risk, measures such as applying fire-resistant coatings or incorporating fireproof insulation become necessary. 3. Thermal expansion and contraction are factors to be considered. Steel expands and contracts with temperature fluctuations. If the I-beams are not designed or installed properly to accommodate this movement, it can lead to stress and potentially cause structural issues like cracking or buckling. 4. The cost factor should not be overlooked. Steel I-beams can be expensive, particularly for large-scale construction projects. The expenses associated with acquiring, transporting, and installing them can significantly impact the overall budget. 5. The environmental impact of steel production is a significant concern. The process involves substantial energy consumption and generates greenhouse gas emissions. Additionally, the extraction of raw materials like iron ore and coal can have negative environmental consequences. Sustainable alternatives or measures to reduce the carbon footprint associated with steel production must be taken into account. 6. Weight and transportation pose challenges due to the heaviness of steel I-beams. Specialized equipment and meticulous planning are necessary to safely transport and lift these beams into place, thereby increasing the complexity and potential risks of the construction process. 7. Design limitations are also worth considering. Steel I-beams have specific restrictions based on their size and shape. If the structure requires unique or unconventional designs, finding suitable steel beams that meet the specific requirements can be challenging or costly. While steel I-beams are widely used in construction due to their strength and durability, it is crucial to thoroughly assess these potential risks and implement appropriate measures to ensure their safe and effective use in building projects.

- Q: Can Steel I-Beams be used for industrial buildings?

- Certainly, industrial buildings can incorporate steel I-beams. The construction of industrial buildings often relies on steel I-beams because of their remarkable strength, durability, and flexibility. These beams offer exceptional structural support, enabling wider spans and greater load capacities, which makes them perfect for industrial purposes. They exhibit resilience against heavy loads and ensure stability and resistance in adverse weather conditions. Furthermore, steel I-beams can be conveniently tailored and modified to fulfill precise design specifications, making them highly favored for efficient and economical construction in industrial buildings.

- Q: Can steel I-beams be used for educational institutions?

- Yes, steel I-beams can be used for educational institutions. Steel I-beams are commonly used in construction due to their high strength and load-bearing capabilities. They can provide structural support for buildings, including educational institutions, ensuring safety and stability. Additionally, steel I-beams offer design flexibility, allowing for spacious and open interior spaces within educational buildings.

Send your message to us

Chinese Standard Hot Rolled Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches