Steel Equal Angle Bar for Tower Construction with Small Tolerance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Equal Angle Bar Description:

Steel equal angle bar is a main kind of structure steel and the section is like a letter L. We use steel equal angle bar for tower construction. Steel equal angle bar can be erected as soon as the materials are delivered on site. High strength, stiffness, toughness, and ductile properties are advantages of this kind of steel equal angle bar.

2. Main Features of Steel Equal Angle Bar:

• Strength - Having high strength, stiffness, toughness, and ductile properties, structural steel is one of the most commonly used materials in commercial and industrial building construction.

• Constructability - Steel equal angle Bar can be developed into nearly any shape, which are either bolted or welded together in construction. Structural steel can be erected as soon as the materials are delivered on site, whereas concrete must be cured at least 1–2 weeks after pouring before construction can continue, making steel a schedule-friendly construction material.

• Fire resistance - Steel is inherently a noncombustible material. However, when heated to temperatures seen in a fire scenario, the strength and stiffness of the material is significantly reduced. The steel equal angle bar can be enveloped in sufficient fire-resistant materials, increasing overall cost of steel structure buildings.

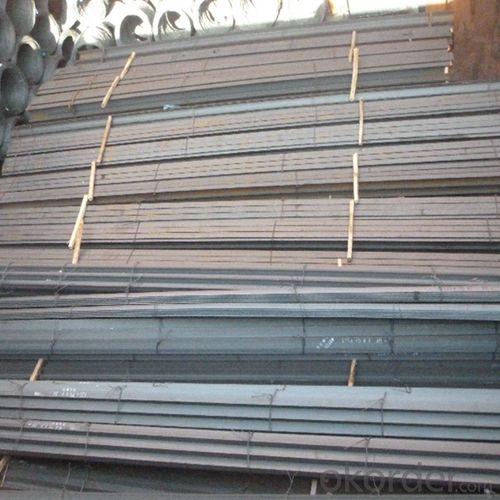

3. Steel Equal Angle Bar Images:

4. Steel Equal Angle Bar Specification:

Angle | KG/M | Angle | KG/M | Angle | KG/M | Angle | KG/M |

20X20X3 | 0.889 | 60X60X5 | 4.570 | 90X90X8 | 10.946 | 130X130X12 | 23.600 |

20X20X4 | 1.145 | 60X60X6 | 5.427 | 90X90X9 | 12.220 | 130X130X13 | 25.400 |

25X25X2 | 0.763 | 63X63X4 | 3.907 | 90X90X10 | 13.476 | 130X130X14 | 27.200 |

25X25X3 | 1.124 | 63X63X5 | 4.822 | 90X90X15 | 15.940 | 130X130X16 | 30.900 |

25X25X4 | 1.459 | 63X63X6 | 5.721 | 100X100X6 | 9.366 | 140X140X10 | 21.488 |

30X30X2 | 0.922 | 63X63X8 | 7.469 | 100X100X7 | 10.830 | 140X140X12 | 25.522 |

30X30X3 | 1.373 | 63X63X10 | 9.151 | 100X100X8 | 12.276 | 140X140X14 | 29.490 |

30X30X4 | 1.786 | 70X70X4 | 4.372 | 100X100X10 | 15.120 | 140X140X15 | 31.451 |

36X36X3 | 1.656 | 70X70X5 | 5.397 | 100X100X12 | 17.898 | 140X140X16 | 33.393 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about the corrosion of the products?

When the steel equal angle bar in contact with water, can corrode, creating a potentially dangerous structure. Measures must be taken in structural steel construction to prevent any lifetime corrosion. The steel can be painted, providing water resistance. Also, the fire resistance material used to envelope steel is commonly water resistant.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.③What is the difference between steel angle bar and traditional material?

Steel equal angle bar differs from concrete in its attributed compressive strength as well as tensile strength.

- Q: Can steel angles be used in sign support structures?

- Yes, steel angles can be used in sign support structures. Steel angles are commonly used in construction as they provide excellent strength and structural support. They can be easily welded or bolted together to form sturdy sign support structures that can withstand various weather conditions and loads.

- Q: Can steel angles be used in railway track construction?

- Indeed, steel angles find utility in the construction of railway tracks. They serve as a crucial structural element, lending robustness and steadiness to the track system. By bolstering the train's weight and facilitating even load distribution, they play a pivotal role. Steel angles are frequently employed in the fabrication of rail joints, which connect two rail sections, as well as in the installation of rail fastenings and track accessories. Additionally, their durability, resistance to wear, and ability to withstand substantial loads and high impact forces make them an optimal selection for railway track construction.

- Q: What is the maximum cantilever length for a steel angle?

- The maximum cantilever length for a steel angle depends on various factors such as the material strength, the angle's dimensions, and the load it needs to support. Steel angles are commonly used as structural elements in construction and can be designed to support different loads based on their size and configuration. In general, the maximum cantilever length for a steel angle is determined by its ability to resist bending moments and deflection. Bending moments occur when a load is applied to the free end of the cantilever, causing the angle to bend. Deflection is the amount of bending or sagging that occurs under a specific load. To determine the maximum cantilever length, engineers consider the moment of inertia, which is a measure of the angle's resistance to bending, as well as the yield strength of the steel. The moment of inertia is affected by the angle's dimensions, such as the width and thickness of the flanges and the length of the legs. Additionally, the design codes and standards specific to the project or application must be followed to ensure safety and compliance. These codes provide guidelines on the maximum allowable bending stress and deflection limits for steel angles in different loading conditions. In summary, the maximum cantilever length for a steel angle depends on its material strength, dimensions, and the load it needs to support. It is determined through calculations considering the moment of inertia, yield strength, and compliance with relevant design codes and standards.

- Q: What are the advantages of using steel angles over other materials?

- There are several advantages of using steel angles over other materials. Firstly, steel angles offer exceptional strength and durability, making them suitable for a wide range of structural applications. They can withstand heavy loads and provide reliable support, ensuring structural integrity. Additionally, steel angles are versatile as they can be easily customized and fabricated to meet specific design requirements. They are also cost-effective in terms of long-term maintenance and repair, as steel is highly resistant to corrosion and requires minimal upkeep. Lastly, steel angles offer excellent fire resistance, making them a safe choice for construction projects.

- Q: How do steel angles perform under cyclic loading?

- Steel angles perform well under cyclic loading due to their high strength and stiffness. They are capable of resisting repeated loading and can withstand significant stress and strain without experiencing fatigue failure. The structural design of steel angles allows them to efficiently distribute and dissipate the applied loads, making them reliable and durable in cyclic loading conditions.

- Q: Can steel angles be used to create decorative elements in architecture?

- Yes, steel angles can definitely be used to create decorative elements in architecture. These versatile structural components can be bent or shaped into various angles and forms, allowing architects and designers to incorporate them into the overall aesthetic of a building. From ornamental railings and window frames to decorative beams and columns, steel angles offer both strength and design possibilities, making them an ideal choice for decorative elements in architecture.

- Q: What are the different types of connections used for steel angles in educational institutions?

- There are several types of connections commonly used for steel angles in educational institutions. These include bolted connections, welded connections, and clip angles. Bolted connections involve using bolts and nuts to secure the steel angles together. Welded connections, on the other hand, involve fusing the steel angles together using heat. Clip angles are small pieces of steel that are used to connect and reinforce the steel angles. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the load requirements, cost, and construction method.

- Q: Can steel angles be used for shelving?

- Yes, steel angles can be used for shelving. Steel angles are commonly used in shelving systems due to their durability and strength. They provide sturdy support for shelves and can withstand heavy loads. Additionally, steel angles are versatile and can be easily customized to fit different shelving configurations. They are often used in industrial settings, warehouses, garages, and even in residential applications where a strong and reliable shelving solution is desired.

- Q: How do you reinforce a steel angle for added stability?

- One way to reinforce a steel angle for added stability is by adding gussets or diagonal braces. These additional elements can be attached to the steel angle to increase its strength and resistance to bending or twisting forces.

- Q: What are the fire resistance properties of steel angles?

- Steel angles, known as L-shaped metal bars, possess exceptional fire resistance properties. Their high melting point and inability to easily combust or support the spread of fire are due to the composition and structure of steel. In the event of a fire, steel angles maintain their structural integrity for an extended period, allowing occupants to evacuate and firefighters to control the situation. This fire resistance is attributed to steel's non-combustible nature and efficient heat dissipation. Furthermore, steel angles have low thermal conductivity, which prevents the rapid spread of fire and reduces the risk of structural failure. Consequently, fire-resistant building designs and constructions often incorporate steel angles as a reliable and safe option for structural support in fire-prone environments.

Send your message to us

Steel Equal Angle Bar for Tower Construction with Small Tolerance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords