Hot rolled square steel billet prime steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 29437 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

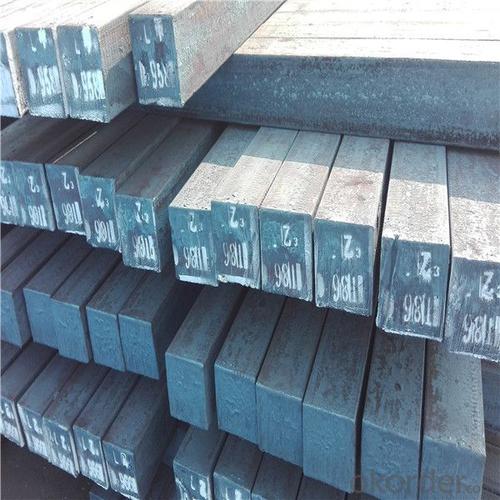

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the main types of steel billet rolling mills?

- Various types of steel billet rolling mills exist, each possessing unique characteristics and functionalities to cater to the diverse requirements of different industries. 1. Two-high rolling mills: These mills comprise two horizontally mounted rolls rotating in opposite directions. Two-high mills are commonly utilized for shaping and reducing the thickness of steel billets. They boast a relatively simple design and are suitable for light to medium-duty applications. 2. Three-high rolling mills: Three-high mills consist of three rolls arranged vertically in a triangular configuration. The upper and lower rolls are driven, while the middle roll remains idle and adjustable. This design allows for greater flexibility in shaping and reducing the dimensions of the billet. Three-high mills are often employed to produce high-quality finished products with precise dimensions and surface finishes. 3. Four-high rolling mills: Four-high mills possess four rolls, including two small diameter work rolls and two larger diameter backup rolls. The work rolls are driven, while the backup rolls provide support and adjust the billet's thickness. Four-high mills are highly versatile and can be utilized for a wide range of applications, encompassing both hot and cold rolling processes. 4. Cluster mills: Cluster mills consist of multiple small-diameter rolls arranged in a cluster. These rolls collaborate to reduce the billet's thickness and shape it into the desired form. Cluster mills are commonly utilized to produce high-precision products such as wires and thin strips. 5. Steckel mills: Steckel mills are specialized rolling mills designed for the production of heavy-gauge plates and strips. They incorporate a combination of a reversible rolling mill and a continuous casting machine. Steckel mills are renowned for their high productivity and the capability to manufacture a wide array of steel products with excellent surface quality. Each type of steel billet rolling mill boasts specific advantages and is suitable for particular applications. The selection of a mill depends on factors including the desired final product, required dimensions, production volume, and budgetary limitations.

- Q: What are the specifications for stainless steel billets used in the marine industry?

- Stainless steel billets used in the marine industry must adhere to specific specifications to ensure optimal performance and durability in harsh marine environments. These specifications typically include the following: 1. Material Composition: Stainless steel billets for marine applications are usually made from austenitic stainless steel grades such as 304, 316, or 316L. These grades offer excellent corrosion resistance, high strength, and good weldability. 2. Corrosion Resistance: The stainless steel billets must have high resistance to corrosion caused by saltwater, moisture, and other aggressive marine elements. They should exhibit excellent resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking. 3. Mechanical Properties: The billets should possess sufficient tensile strength, yield strength, and elongation to withstand the demanding conditions encountered in the marine industry. These properties ensure that the stainless steel can handle the heavy loads, vibrations, and impacts experienced at sea. 4. Heat Treatment: Proper heat treatment processes, such as annealing, may be required to enhance the stainless steel's mechanical properties and corrosion resistance. Heat treatment can also eliminate residual stresses and improve the material's toughness. 5. Surface Finish: The surface of the billets should be free from defects, such as cracks, pits, and inclusions, which could compromise the structural integrity or promote corrosion. A smooth, polished surface is often desired to minimize friction and facilitate easier cleaning. 6. Dimensional Tolerance: Stainless steel billets used in the marine industry must adhere to specific dimensional tolerances to ensure compatibility with other marine components and facilitate ease of manufacturing and assembly. 7. Certification: Billets for the marine industry may need to meet various certification standards, such as ASTM, ISO, or specific industry standards like the American Bureau of Shipping (ABS) or Det Norske Veritas Germanischer Lloyd (DNV-GL) certifications. These certifications ensure that the stainless steel meets the required quality and safety standards. Overall, the specifications for stainless steel billets used in the marine industry focus on corrosion resistance, mechanical properties, heat treatment, surface finish, dimensional tolerances, and adherence to relevant certifications. These specifications ensure that the stainless steel billets can withstand the harsh marine environment, prolonging the lifespan of marine structures and components.

- Q: How do steel billets contribute to the manufacturing of rail and transportation systems?

- Steel billets are crucial in the manufacturing process of rail and transportation systems. These billets serve as the primary material used to produce various components needed for railway construction, including rails, sleepers, and fasteners. One of the main applications of steel billets in rail manufacturing is for the creation of railway tracks. Initially, the steel billets are heated and then rolled into long, slim sections known as rails. These rails undergo further processing and treatment to endure the heavy loads and constant wear and tear experienced in railway operations. The durability, strength, and resistance to deformation of steel make it a perfect material for railway tracks, ensuring transportation safety and efficiency. Steel billets also have a vital role in the manufacturing of sleepers or railroad ties, which provide support to the rails and maintain their alignment. These sleepers, typically made from prestressed concrete or wood, require reinforcing bars made from steel billets to enhance their strength and structural integrity. Additionally, steel billets are used to produce fasteners like bolts, clips, and spikes, which are essential for securely attaching rails to sleepers and maintaining track stability. Furthermore, steel billets are utilized in the production of various components for transportation systems, including chassis, frames, and suspension systems for trains, trams, buses, and other vehicles. The high strength and excellent formability of steel billets make them an ideal choice for these applications, as they can withstand heavy loads and provide the necessary structural integrity for safe and reliable transportation. To conclude, steel billets play a significant role in the manufacturing of rail and transportation systems. From railway track production to the fabrication of sleepers, fasteners, and vehicle components, steel billets offer the required strength, durability, and structural integrity for the efficient and safe operation of railways and transportation systems.

- Q: How are steel billets unloaded at the destination?

- Steel billets are typically unloaded at the destination using heavy machinery such as cranes or forklifts. These machines carefully lift and transport the steel billets from the transport vehicle to the designated storage area.

- Q: What are the main factors affecting the corrosion resistance of carbon steel billets?

- The corrosion resistance of carbon steel billets is influenced by several main factors. 1. Composition: The composition of carbon steel billets plays a significant role in their corrosion resistance. The presence of certain alloying elements, such as chromium, nickel, and copper, can improve the resistance to corrosion. These elements form a protective layer on the surface of the steel, preventing the formation of rust or other corrosive products. 2. Environmental conditions: The environment in which the carbon steel billets are exposed also affects their corrosion resistance. Factors such as humidity, temperature, pH level, and the presence of corrosive substances like acids or salts can accelerate corrosion. High humidity and acidic conditions, for example, can increase the rate of corrosion. 3. Surface condition: The surface condition of the carbon steel billets is crucial for their corrosion resistance. Any imperfections, scratches, or roughness on the surface can act as initiation sites for corrosion. It is important to have a smooth and clean surface to minimize the chances of corrosion. 4. Protective coatings: Applying protective coatings, such as paints, varnishes, or corrosion inhibitors, can significantly enhance the corrosion resistance of carbon steel billets. These coatings act as a barrier between the steel surface and the corrosive environment, preventing direct contact and reducing the rate of corrosion. 5. Galvanic corrosion: Carbon steel billets can undergo galvanic corrosion when they are in contact with dissimilar metals or alloys in the presence of an electrolyte. The difference in electrical potential between the metals creates a galvanic cell, leading to accelerated corrosion of the less noble metal (carbon steel). Proper insulation or the use of sacrificial anodes can help minimize galvanic corrosion. In conclusion, the corrosion resistance of carbon steel billets is influenced by factors such as their composition, environmental conditions, surface condition, protective coatings, and the possibility of galvanic corrosion. By considering these factors and implementing appropriate measures, the corrosion resistance of carbon steel billets can be effectively improved.

- Q: How are steel billets used in the manufacturing of railway tracks?

- Steel billets are an essential component in the manufacturing of railway tracks. These billets serve as the raw material from which the tracks are formed. The process begins with the steel billets being heated to a high temperature, typically around 1200 degrees Celsius, in a furnace. This heating process helps to soften the steel and make it more malleable. Once the billets are heated, they are passed through a series of rollers in a process known as hot rolling. This process involves the billets being continually passed through the rollers to gradually reduce their thickness and shape them into long, slender strips. This hot rolling process also helps to refine the internal structure of the steel, improving its strength and durability. After the hot rolling process, the steel strips are then cut into smaller sections, known as rails. These rails are carefully inspected for any defects or imperfections before they are further processed. They undergo a process called finishing, where any surface irregularities or imperfections are removed through grinding or polishing. The finished rails are then treated with various techniques to enhance their strength and resistance to wear and tear. This may include heat treatment processes such as quenching and tempering, which further improve the rails' hardness and toughness. Additionally, the rails may be coated with protective layers to prevent corrosion and extend their lifespan. Finally, the rails are transported to the construction site where they are laid and fastened to the sleepers or ties to form the railway track. The steel rails provide a sturdy and reliable foundation for trains to travel on, with their strength and durability enabling them to withstand heavy loads and constant use. In conclusion, steel billets play a crucial role in the manufacturing of railway tracks. They are transformed through various processes into rails that provide a solid foundation for trains to run on. The use of steel billets ensures that the railway tracks are strong, durable, and capable of withstanding the demands of heavy train traffic.

- Q: What are the different methods of steel billet surface etching?

- There are several different methods of steel billet surface etching that are commonly used in various industries. These methods include chemical etching, electrolytic etching, and laser etching. 1. Chemical etching: This method involves immersing the steel billet in a chemical solution, usually an acid, that selectively removes a thin layer of material from the surface. The choice of the chemical solution depends on the specific requirements of the etching process, such as the desired depth and pattern. Commonly used chemicals for steel etching include hydrochloric acid, nitric acid, and ferric chloride. 2. Electrolytic etching: In this method, an electric current is passed through the steel billet while it is immersed in an electrolyte solution. The current causes a controlled dissolution of the surface metal, resulting in a desired etched pattern. Electrolytic etching offers precise control over the etching process and can produce intricate and detailed designs. It is often used for marking or labeling steel billets with logos, serial numbers, or other identification marks. 3. Laser etching: Laser etching is a non-contact and highly precise method of surface etching. It involves using a laser beam to selectively remove material from the steel billet surface. The laser beam is directed and controlled by computer software, allowing for intricate and customizable designs. Laser etching can be used to create permanent markings, logos, or patterns on steel billets. It is widely used in industries such as automotive, aerospace, and electronics. Each of these methods has its advantages and limitations, and the choice of the etching method depends on factors such as the desired design, the material properties of the steel billet, and the production requirements.

- Q: What are the different types of steel billet welding processes?

- There are several types of steel billet welding processes, including submerged arc welding (SAW), gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). These processes differ in the type of electrode and shielding method used, as well as the specific conditions and equipment required for each process.

- Q: How are steel billets used in the production of forged parts?

- Forged parts rely heavily on steel billets, as they are crucial for their production. These billets act as the initial material from which the desired shape and size of the forged part are achieved. To commence the process, steel billets are subjected to specific heating, which renders them more malleable. This heating, referred to as forging temperature, allows the steel to be easily manipulated without any risk of cracking or breaking. The elevated temperature also enhances the structural integrity of the billets and makes them more resistant to deformation during the forging procedure. Once the steel billets reach the desired temperature, they are positioned onto a forging press or hammer. The press exerts immense pressure on the billets, compelling them to take the form of the die or mold within which they are placed. This procedure, known as forging, enables the creation of intricate details and complex shapes that cannot be achieved through alternative manufacturing techniques. The forged parts crafted from steel billets are renowned for their exceptional strength, durability, and resistance to wear and tear. They find extensive application in various industries, including automotive, aerospace, oil and gas, and construction. Forged parts can range from small components like gears and bolts to larger items such as crankshafts, connecting rods, and turbine blades. In conclusion, steel billets play a vital role in the production of forged parts by serving as the raw material that undergoes shaping and forming during the forging process. The resulting forged parts exhibit superior mechanical properties and are indispensable components in numerous industrial applications.

- Q: What are the international standards or certifications for steel billets?

- The international standards or certifications for steel billets include ASTM A615/A615M-20, ASTM A706/A706M-16, BS 4449:2005+A3:2016, and EN 10025-2:2004. These standards provide specifications for the chemical composition, mechanical properties, and dimensions of steel billets, ensuring their quality and suitability for various applications in the construction industry.

Send your message to us

Hot rolled square steel billet prime steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 29437 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords