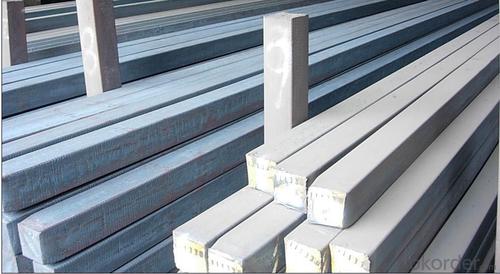

Hot Rolled Steel Billet 3SP Standard 130mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 130mm

Description of Hot Rolled Steel Billet 3SP Standard 130mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 130mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 130mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 130mm

Product | Hot Rolled Steel Billet 3SP Standard 130mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 130mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: How are steel billets packaged for shipment?

- Steel billets are typically packaged for shipment by placing them on wooden pallets or in steel cages. They are then secured using steel strapping or shrink wrap to prevent movement or damage during transportation. Labels are also attached to the packaging to identify the type, quantity, and destination of the billets.

- Q: What are the main challenges in the transportation of steel billets?

- The main challenges in the transportation of steel billets include ensuring proper handling and securing of the heavy and bulky loads, preventing damage or deformation during loading and unloading processes, and complying with safety regulations for transporting hazardous materials. Additionally, factors such as limited availability of specialized equipment, fluctuations in fuel prices, and coordinating logistics for long-distance shipments can pose challenges for efficient and cost-effective transportation of steel billets.

- Q: What are the potential applications of steel billets in the agricultural aftermarket?

- Steel billets have several potential applications in the agricultural aftermarket. They can be used to fabricate various agricultural machinery and equipment such as plows, harrows, cultivators, and seeders. Additionally, steel billets can be utilized to manufacture durable and sturdy structures like barns, fences, and storage sheds, which are essential in the agricultural industry. The versatility and strength of steel make it an ideal material for these applications, ensuring longevity and reliability in demanding agricultural environments.

- Q: How does the quality of steel billets affect the quality of the final product?

- The quality of steel billets significantly impacts the quality of the final product. The composition, purity, and uniformity of the steel billets directly influence the structural integrity, strength, and performance of the finished steel product. Imperfections or impurities in the billets can lead to defects, such as cracks or weak spots, in the final product. Therefore, ensuring high-quality steel billets is crucial in producing a superior final steel product.

- Q: Can steel billets be used in the production of jewelry?

- Steel billets are typically not used in the production of jewelry due to their composition and properties. Steel is an alloy primarily composed of iron and carbon, with additional elements such as manganese, chromium, and nickel. This composition gives steel its strength and durability, making it ideal for various industrial applications, but not for jewelry production. Jewelry is often crafted from precious metals like gold, silver, and platinum, which possess unique characteristics that make them suitable for adornment. These metals are malleable, meaning they can be easily shaped and molded into intricate designs. Additionally, they have a lustrous appearance and are resistant to tarnishing or corrosion. Steel, on the other hand, is much harder and less ductile compared to precious metals. It cannot be easily manipulated into delicate and intricate shapes required for jewelry making. Furthermore, steel has a dull gray color, which does not provide the desired aesthetic appeal in jewelry. While it is technically possible to create jewelry using steel billets, it is not a common practice due to the aforementioned reasons. Steel is primarily used in industries where its high strength and durability are necessary, such as construction, automotive, and machinery manufacturing.

- Q: What are the different surface treatments for improved corrosion resistance in steel billets?

- Steel billets can undergo different surface treatments to enhance their resistance to corrosion. These treatments aim to establish a protective barrier on the steel's surface, preventing corrosive agents from reaching the metal beneath. Some commonly used surface treatments for improved corrosion resistance in steel billets include: 1. Hot-dip galvanizing: Immersing the steel billets in molten zinc creates a galvanized coating, which is a zinc-iron alloy. This coating offers excellent corrosion resistance and prolongs the lifespan of the steel billets. 2. Electroplating: Through electroplating, a thin layer of metal such as zinc or nickel is applied to the steel billets using an electric current. This layer acts as a protective barrier against corrosion and provides an attractive finish. 3. Powder coating: By applying a dry powder mixture of resin and pigment to the steel billets and heating it, a durable and corrosion-resistant layer is formed. Powder coating is available in various colors and finishes. 4. Paint coatings: Applying corrosion-resistant paint to steel billets creates a protective barrier that hinders moisture and corrosive agents from reaching the steel. Multiple layers of paint can be added for enhanced durability and longevity. 5. Passivation: Passivation is a chemical process that eliminates free iron and contaminants from the steel billets' surface. This process prevents corrosion and encourages the formation of a protective oxide layer. Passivation is often combined with other surface treatments like electroplating or powder coating to enhance corrosion resistance. It is important to consider factors such as the billets' operating environment, desired lifespan, and cost considerations when choosing a surface treatment for improved corrosion resistance. A thorough evaluation of specific requirements and professional consultation are crucial in determining the most suitable treatment option.

- Q: What is the average lead time for ordering steel billets?

- The lead time for ordering steel billets can vary depending on several factors, including the supplier, quantity needed, production capacity, and current market conditions. Typically, the lead time can range from a few weeks to a couple of months. If the supplier has readily available stock or a short production cycle, the lead time may be shorter, usually around two to four weeks. However, if the supplier needs to produce the steel billets specifically for the order, it may take longer. In such cases, the lead time can extend to six to eight weeks or even longer, particularly if there are any production process delays. Considering the quantity required is also crucial. Smaller orders may have shorter lead times compared to larger quantities, as they can be accommodated within the supplier's existing production schedule or available stock. Furthermore, market conditions play a significant role. When there is high demand or disruptions in the supply chain, lead times may increase due to heightened competition for resources and longer production cycles. To obtain an accurate estimate of the average lead time for ordering steel billets, it is advisable to contact multiple suppliers and discuss your specific requirements with them. They can provide more precise information based on their production capabilities and the current market conditions.

- Q: What are the different international trade regulations for steel billets?

- There are several international trade regulations that govern the trade of steel billets. These regulations aim to promote fair trade practices, ensure product quality, and prevent unfair competition. Some of the key regulations for steel billets include: 1. Tariffs and duties: Many countries impose tariffs or import duties on steel billets to protect domestic steel industries. These tariffs can vary significantly between countries and may change periodically. Importers and exporters need to be aware of these tariffs and factor them into their pricing and cost calculations. 2. Anti-dumping measures: Anti-dumping regulations are in place to prevent the sale of steel billets in foreign markets at prices lower than their production cost, which can harm domestic industries. If a country determines that steel billets are being dumped into their market, they may impose anti-dumping duties or other measures to address the issue. 3. Trade agreements and trade barriers: International trade agreements, such as free trade agreements or regional trade blocs, can affect the trade of steel billets. These agreements may reduce or eliminate tariffs and other trade barriers between participating countries, promoting smoother trade flows. Conversely, countries not party to such agreements may face higher trade barriers, making it more challenging to export or import steel billets. 4. Quality and safety standards: Steel billets must meet specific quality and safety standards set by importing countries. These standards may include specifications for dimensions, chemical composition, mechanical properties, and other attributes. Importers and exporters need to ensure their steel billets comply with these standards to avoid rejection or additional inspection upon arrival. 5. Export controls: Some countries impose export controls or restrictions on certain goods, including steel billets, to ensure domestic supply or protect national security interests. These controls can limit the quantity or destination of steel billet exports, requiring exporters to obtain licenses or permits before shipping. 6. Documentation and customs requirements: International trade of steel billets requires proper documentation and adherence to customs procedures. Exporters must provide accurate and complete documentation, including commercial invoices, packing lists, certificates of origin, and other relevant documents. Importers must comply with customs requirements and pay any applicable duties or fees. It is essential for businesses involved in the trade of steel billets to stay informed about these international trade regulations. They should regularly monitor changes in tariffs, anti-dumping measures, trade agreements, and quality standards to ensure compliance and make informed business decisions.

- Q: Does anyone know how much it costs to refine a ton of steel? What are the expenses involved?

- Electricity, water, wages, raw materials, raw materials loss, charges, oxygen, according to their own circumstances, as well as freight and other expenses,

- Q: How are steel billets used in the automotive industry?

- Steel billets are used in the automotive industry to produce various components such as engine blocks, crankshafts, connecting rods, suspension parts, and chassis components. These billets are heated and then shaped through various manufacturing processes like forging, casting, or extrusion to create the necessary automotive parts. The high strength and durability of steel make it an ideal material for ensuring the structural integrity and safety of vehicles.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 130mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords