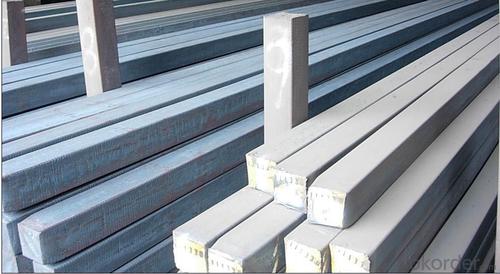

Hot Rolled Square Steel Billet 3SP Standard 135mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 135mm

Description of Hot Rolled Square Steel Billet 3SP Standard 135mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 135mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 135mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 135mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 135mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc.

- Q: What is the average cost of steel billets?

- Several factors can influence the average cost of steel billets, including the type of steel, market conditions, and global supply and demand. Steel billets are semi-finished metal products commonly used as raw materials for various steel products. As of September 2021, the average price of steel billets ranges from $400 to $600 per metric ton. However, it is important to be aware that this price can fluctuate significantly due to factors such as changes in raw material costs (such as iron ore and scrap metal), energy prices, transportation costs, and market dynamics. Furthermore, specific countries or regions may experience variations in the average cost of steel billets due to regional factors like import tariffs, trade restrictions, and currency exchange rates. It is always recommended to seek advice from industry experts, steel suppliers, or consult market reports for the most accurate and up-to-date information on the current average cost of steel billets.

- Q: How do steel billets contribute to the manufacturing of consumer goods?

- Steel billets play a crucial role in the manufacturing of consumer goods by serving as the raw material for a wide range of products. These billets are essentially semi-finished steel products that are created through the casting process. They are solid blocks of steel that are heated and then shaped into a specific form, which can vary depending on the intended application. One of the primary ways steel billets contribute to the manufacturing of consumer goods is through their use in the production of various metal parts. These parts can be found in a multitude of products, such as automobiles, appliances, machinery, and furniture. By using steel billets as the starting material, manufacturers can create components that are strong, durable, and resistant to wear and tear. This ensures that the final consumer goods have a long lifespan and can withstand the demands of everyday use. Furthermore, steel billets are often used in the construction industry for the production of structural steel beams, columns, and other building materials. These components are crucial for the construction of infrastructure, residential buildings, commercial complexes, and other structures. Steel's high strength-to-weight ratio makes it an ideal material for these applications, providing the necessary structural support while minimizing the overall weight and cost. In addition to their strength and durability, steel billets also offer versatility in terms of their formability and machinability. This means that they can be easily shaped, welded, and cut into various sizes and designs, allowing manufacturers to tailor the steel components to meet specific consumer needs. This flexibility enables the production of a wide range of consumer goods, from small intricate parts to large complex structures. The use of steel billets in the manufacturing of consumer goods also contributes to sustainability. Steel is a highly recyclable material, and the production of steel products using recycled steel requires significantly less energy and resources compared to using virgin materials. This helps reduce the environmental impact associated with consumer goods production and promotes a more circular economy. Overall, steel billets are a crucial ingredient in the manufacturing of consumer goods. Their strength, durability, versatility, and recyclability make them an ideal material choice for producing a wide range of products that meet the needs and expectations of consumers.

- Q: Can steel billets be welded together?

- Indeed, it is possible to weld steel billets together. Welding serves as a widely employed technique for connecting steel billets, which are partially finished goods taking the shape of solid metal rectangles or squares. Through the application of heat and pressure, the steel billets can be combined, resulting in a robust and resilient bond. The utilization of welding methods such as arc welding, gas welding, and laser welding is contingent upon the particular demands and characteristics of the steel. Nevertheless, it is imperative to acknowledge that the correct welding approach and proficiency are vital in guaranteeing a triumphant and superior weld joint.

- Q: How are steel billets used in the manufacturing of industrial valves?

- Industrial valves rely heavily on steel billets as a vital element in their production. These valves are critical devices utilized to regulate the movement of fluids and gases in a wide range of industrial operations. Steel billets, which are partially processed metal products, play a crucial role in the creation of these valves. The manufacturing process for industrial valves typically involves multiple stages, including forging, machining, and assembly. Steel billets are primarily employed during the forging phase of valve production. Forging is the technique of shaping metal by applying localized compressive forces using dies or hammers. Steel billets are heated to a specific temperature and then subjected to intense pressure, causing them to take on the desired shape. The use of steel billets in the forging of valves presents several advantages. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for valves operating under high-pressure conditions. Steel billets supply the necessary raw material to create sturdy and dependable valve components. Furthermore, steel billets can be easily molded and shaped during the forging process. This allows manufacturers to craft intricate valve designs with precision and accuracy. The versatility of steel billets facilitates the production of valves in various sizes, shapes, and configurations to meet specific industrial requirements. Moreover, steel billets can undergo heat treatment after forging to enhance their mechanical properties. Heat treatment methods such as quenching and tempering can greatly improve the hardness, strength, and wear resistance of valve components. This ensures that the valves can withstand demanding operating conditions and deliver optimal performance over an extended period. In conclusion, the utilization of steel billets is indispensable in the manufacturing of industrial valves. These billets provide the raw material necessary for forging robust valve components, offering strength, durability, and versatility. Leveraging steel billets enables the production of high-quality valves capable of efficiently controlling the flow of fluids and gases in industrial processes.

- Q: Are steel billets used in the production of furniture?

- No, steel billets are typically not used in the production of furniture. Steel billets are semi-finished products made from molten iron that are later shaped into various forms, such as bars, rods, or sheets, through a process called hot rolling. While steel may be used in the manufacturing of furniture, it is usually in the form of finished products such as steel tubing, steel sheets, or steel frames. These finished steel products are more commonly used in the construction of furniture, particularly in industrial or modern designs. The use of steel in furniture production provides durability, strength, and a sleek aesthetic. However, the steel used in furniture manufacturing is usually obtained through different processes than the production of steel billets.

- Q: How do steel billets contribute to the manufacturing of construction supplies?

- Steel billets are the primary raw material used in the manufacturing of construction supplies. These billets are heated and then shaped into various forms such as bars, rods, beams, and plates, which are essential components in construction projects. They provide the necessary strength, durability, and structural integrity required for buildings, bridges, and other infrastructure. The versatility and quality of steel billets make them indispensable in the construction industry.

- Q: Who knows the diamond is?Who knows the diamond is carbon? Is it C60?

- It is also called the diamond diamond, crystal, it is not the molecules themselves, so the formula does not apply to.C said it is only by this kind of carbon elements. While C60 is footballene is another matter, the 60 is because it is a molecular crystal, each molecule consists of 60 carbon.

- Q: What are the international standards or certifications for steel billets?

- Steel billets are subject to various international standards and certifications, which guarantee their quality, safety, and compliance with industry regulations. One widely recognized standard is the ISO 9001 certification, which establishes criteria for a quality management system. This certification ensures that steel billet production adheres to international quality standards and consistently meets customer requirements. In addition to ISO 9001, the steel industry has other specific certifications. The ISO 14001 certification focuses on environmental management systems, ensuring that steel billet production follows sustainable practices. This certification demonstrates a commitment to minimizing environmental impact and promoting sustainable development. Another crucial certification is the ISO 45001, which emphasizes occupational health and safety management. This certification verifies that steel billet manufacturers have implemented effective safety protocols and procedures to protect employees and prevent workplace accidents. Moreover, the American Society for Testing and Materials (ASTM) establishes standards for steel billets, such as ASTM A615/A615M for deformed and plain carbon-steel bars used in concrete reinforcement. These standards outline mechanical properties, chemical composition, and testing methods for steel billets used in construction applications. Similarly, the European Committee for Standardization (CEN) sets standards for steel billets through the European Norm (EN) system. For example, EN 10025 specifies technical delivery conditions for structural steel products, including steel billets, used in various European industries. Adhering to these international standards and certifications is crucial for steel billet manufacturers. It ensures the quality, safety, and compliance of their products. Conforming to these standards not only enhances the manufacturer's credibility and reputation but also provides customers with confidence that the steel billets they purchase meet the highest industry standards.

- Q: How do steel billets contribute to the overall durability of a structure?

- Steel billets are a crucial component in the construction industry, playing a significant role in enhancing the overall durability of structures. These billets are created by casting molten steel into a solid form, which is then further processed into various shapes and sizes for use in construction projects. One of the main ways in which steel billets contribute to the durability of a structure is through their high strength and load-bearing capacity. Steel is known for its exceptional strength-to-weight ratio, meaning it can withstand heavy loads and stresses without sacrificing its structural integrity. When used in the construction of a building, steel billets provide the necessary strength to support the weight of the entire structure, ensuring it can withstand various environmental and operational factors for a prolonged period. Furthermore, steel billets offer excellent resistance to corrosion, which is a common cause of structural deterioration. Steel is inherently resistant to rust and other forms of corrosion, making it an ideal material for structures that are exposed to moisture, humidity, or harsh weather conditions. This resistance to corrosion ensures that the structure remains intact and structurally sound over time, reducing the need for frequent maintenance and repairs. Another significant contribution of steel billets to the durability of a structure is their ability to withstand extreme temperatures. Steel has a high melting point, allowing it to maintain its structural integrity even under intense heat. This property is particularly crucial in ensuring the safety and longevity of structures in high-temperature environments, such as industrial facilities or buildings near fire-prone areas. Furthermore, steel billets can also enhance the overall resilience of a structure against external forces, such as earthquakes or strong winds. Due to its high elasticity and ductility, steel can absorb and dissipate energy more effectively than other materials, reducing the risk of structural failure during seismic events or extreme weather conditions. In summary, steel billets contribute to the overall durability of a structure in several ways. Their high strength, load-bearing capacity, resistance to corrosion, ability to withstand extreme temperatures, and resilience against external forces make them an ideal material for constructing long-lasting and robust structures. By utilizing steel billets in construction projects, engineers can ensure the durability and safety of structures for years to come.

- Q: How are steel billets used in the manufacturing of energy sector components?

- Steel billets are crucial in the production of various components used in the energy sector. These billets are typically created through continuous casting, a process where liquid steel is poured into a mold and solidifies into a long, rectangular shape. Within the energy sector, steel billets are the primary raw material for manufacturing a wide range of components. One common application is in the production of pipelines. These billets are heated and then rolled or forged to create seamless or welded pipes, which are used to transport oil, gas, and other fluids over long distances. The strength and durability of steel make it an excellent material for pipelines, ensuring the safe and efficient transportation of energy resources. Steel billets also play a role in the production of power generation equipment. They are shaped and machined into components such as turbine blades, shafts, and rotors, which are vital for power plant operation. Steel's exceptional mechanical properties, including high tensile strength and corrosion resistance, make it suitable for withstanding the harsh conditions and high temperatures experienced in power generation processes. Moreover, steel billets are used in the manufacturing of renewable energy infrastructure, like wind turbine towers. These billets are transformed into large cylindrical sections that provide structural support for wind turbines. The strength and stability of steel guarantee that wind turbines can withstand the forces exerted by the wind and efficiently generate electricity. In conclusion, steel billets are essential in the energy sector as they serve as raw materials for pipelines, power generation equipment, and renewable energy infrastructure. Their strength, durability, and resistance to corrosion make them ideal for enduring demanding conditions and ensuring the reliability of energy sector components.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 135mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords