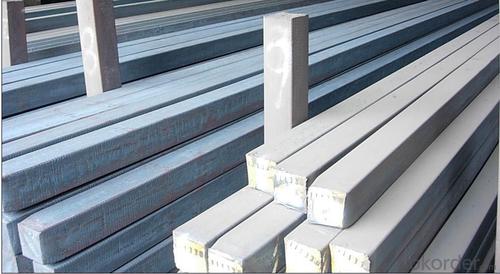

Hot Rolled Steel Billet 3SP Standard 135mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 135mm

Description of Hot Rolled Steel Billet 3SP Standard 135mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 135mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 135mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 135mm

Product | Hot Rolled Steel Billet 3SP Standard 135mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 135mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: What are the different production methods for steel billets?

- There are several different production methods for steel billets, each with its own unique characteristics and advantages. 1. Casting: One of the most common methods is the casting process, where molten steel is poured into a mold and allowed to solidify. This method can be further divided into continuous casting and ingot casting. Continuous casting involves the continuous pouring of molten steel into a water-cooled mold, which results in a continuous solidification process. Ingot casting, on the other hand, involves pouring molten steel into individual molds to create ingots that are then used as raw material for further processing. 2. Direct Reduction: Another method is the direct reduction process, which involves the reduction of iron ore in the presence of a reducing agent such as natural gas or coal. This process produces direct reduced iron (DRI), which can then be used to produce steel billets through subsequent melting and casting processes. 3. Electric Arc Furnace (EAF): The EAF method involves melting scrap steel in an electric arc furnace. This process is commonly used in recycling steel as it allows for the use of various scrap sources, including old cars, appliances, and industrial waste. The molten steel is then cast into billets or other desired shapes. 4. Basic Oxygen Furnace (BOF): The BOF method is a traditional steelmaking process that involves the conversion of molten iron from a blast furnace into steel through the injection of oxygen. This process is used for large-scale production of steel billets and offers high efficiency and flexibility in terms of raw material usage. 5. Powder Metallurgy: Powder metallurgy is an alternative method that involves compacting and sintering metal powders to create solid objects. In the case of steel billets, metal powders are compressed into the desired shape and then heated to a high temperature to achieve solidification. Each of these production methods has its own advantages and is suited for different applications and production scales. The choice of method depends on various factors including the desired properties of the steel, cost considerations, environmental impact, and availability of raw materials.

- Q: What are the main factors affecting the strength of steel billets?

- The main factors affecting the strength of steel billets are the composition of the steel, the heat treatment process, and the presence of any impurities or defects in the billet.

- Q: What are the specifications for stainless steel billets used in the marine industry?

- The specifications for stainless steel billets used in the marine industry typically include a specific grade of stainless steel, such as 316 or 316L, which offers excellent corrosion resistance in marine environments. These billets are often required to meet certain standards, such as ASTM A276 or ASTM A484, which outline the chemical composition, mechanical properties, and dimensional tolerances for stainless steel products. Additionally, the billets may need to undergo specific heat treatment processes, such as annealing or solution treatment, to ensure optimal strength and corrosion resistance.

- Q: What is the role of steel billets in the manufacturing of pressure vessels?

- Steel billets are primarily used in the manufacturing of pressure vessels as the starting material for forging or rolling processes. They are heated and shaped into the desired form, providing the necessary strength, durability, and resistance to high pressure and temperature that pressure vessels require.

- Q: How are steel billets used in the manufacturing of automotive chassis?

- Steel billets are an integral component in the manufacturing of automotive chassis due to their strength and durability. A steel billet is a semi-finished product that is obtained through the process of casting molten steel into a rectangular shape. These billets serve as the raw material for the fabrication of various automotive components, including chassis. The automotive chassis is the structural framework that supports the weight of the vehicle and provides stability and strength. It is responsible for bearing the load and impacts encountered during driving. Steel billets are used to create the main frame of the chassis, which forms the backbone of the vehicle. The steel billets are first heated and then passed through a series of rolling mills to shape them into the desired form, such as I-beams or C-channels, depending on the specific design requirements. This process helps to increase the strength and rigidity of the billets, making them suitable for the demanding conditions encountered by the chassis. Once the steel billets are formed into the desired shape, they are then welded together to create the chassis structure. The joints are carefully welded using various techniques like arc welding or laser welding to ensure a solid and reliable connection. This welding process ensures that the chassis can withstand the stresses and forces experienced during operation, such as acceleration, braking, and cornering. The use of steel billets in the manufacturing of automotive chassis offers several advantages. Steel is known for its high tensile strength, which allows it to withstand heavy loads and impacts without deforming or failing. It also has excellent fatigue resistance, ensuring that the chassis can withstand repeated stress cycles without compromising its structural integrity. Moreover, steel is readily available, cost-effective, and easily recyclable, making it a preferred choice for automotive manufacturers. It also provides excellent corrosion resistance, which is crucial for vehicles exposed to various weather conditions and road environments. In conclusion, steel billets play a crucial role in the manufacturing of automotive chassis by providing the necessary strength and durability. They are shaped and welded to form the main frame, which supports the weight and provides stability to the vehicle. The use of steel billets ensures that the chassis can withstand the demanding conditions of driving, ensuring the safety and performance of the vehicle.

- Q: How are steel billets used in the production of structural steel sections?

- Steel billets are a crucial component in the production of structural steel sections. These billets serve as the primary raw material for the manufacturing process. To begin with, steel billets are melted in a furnace to create molten steel. This molten steel is then cast into billets of specific sizes and shapes, which can vary depending on the desired structural steel section to be produced. The billets are typically rectangular or square in shape. Once the steel billets have solidified, they are reheated in another furnace to a specific temperature for hot rolling. Hot rolling is a process where the billets are passed through a series of rolling mills to reduce their cross-sectional area and shape them into the desired structural steel sections. This process involves applying high pressure and temperature to the billets, which causes them to deform and elongate. The hot rolled steel sections are cooled and then undergo further processing, such as straightening, cutting, and sometimes additional heat treatment to enhance their mechanical properties. These steps ensure that the structural steel sections meet the required specifications for strength, durability, and dimensional accuracy. The structural steel sections produced from steel billets are widely used in various construction projects. They are commonly used in the construction of buildings, bridges, infrastructure, and other structures where strength and load-bearing capacity are essential. These sections can be found in beams, columns, channels, angles, and other shapes that provide the necessary support and structural integrity. Overall, steel billets play a vital role in the production of structural steel sections, serving as the starting material that undergoes a series of manufacturing processes to create the final products used in construction and other industries.

- Q: How are steel billets used in the manufacturing of industrial tools?

- Industrial tools rely on steel billets as a fundamental raw material. These solid steel blocks serve as the foundation for creating various types of tools used in industries like construction, automotive, and manufacturing. To begin the process of tool manufacturing, the steel billets are heated to a specific temperature. This heating process, known as forging, makes the steel more malleable and easier to work with. Once heated, specialized machinery like power hammers and presses shape and form the billets into the desired tool design. During the shaping process, intense pressure is applied to the heated billet, transforming it into the desired tool shape, such as a chisel, wrench, or hammer head. The precise shaping ensures that the tool possesses the necessary strength, durability, and functionality for its intended use. Following the initial shaping, the tool undergoes further refinement and finishing through processes like machining, grinding, and heat treatment. Machining removes excess material and creates needed holes, threads, or features for functionality. Grinding provides a smooth surface finish and precise dimensions. Heat treatment is a critical process that involves subjecting the tool to controlled heating and cooling cycles. This treatment alters the steel's molecular structure, enhancing hardness, strength, and toughness. Different heat treatment techniques, like quenching and tempering, are employed based on specific tool requirements. Once the tool has been shaped, machined, ground, and heat-treated, it undergoes a series of quality checks and inspections to ensure it meets necessary specifications and standards. These checks include dimensional measurements, visual inspections, and functional tests to guarantee the tool is suitable for its intended purpose. In conclusion, steel billets play an integral role in manufacturing durable and high-performing industrial tools. Through shaping, machining, heat treatment, and refinement, these billets are transformed into tools that contribute to efficiency, productivity, and success across various industries. The versatility and strength of steel make it an ideal choice for producing a wide range of tools, further enhancing their performance and longevity.

- Q: Can steel billets be used in the production of aerospace components?

- Yes, steel billets can be used in the production of aerospace components. Steel billets are semi-finished steel products that can be further processed into various shapes and sizes. They are commonly used in industries such as aerospace, automotive, and construction. In the aerospace industry, steel billets can be used to create components such as shafts, gears, and structural parts. However, it is important to note that the specific type of steel used in aerospace applications must meet stringent requirements for strength, durability, and resistance to high temperatures and corrosion. Therefore, steel billets used in aerospace production need to undergo additional processes such as heat treatment, machining, and surface finishing to achieve the required properties and dimensions. Overall, while steel billets can be used in aerospace component production, it is crucial to ensure that the steel material and manufacturing processes meet the necessary specifications and standards for safety and performance in the aerospace industry.

- Q: Are steel billets used in the production of musical instruments?

- Certain musical instruments use steel billets in their production. Steel billets are commonly utilized as a primary component in the manufacturing of steel-string acoustic guitars. Typically, the steel billets are molded into a solid metal rod, which is then employed to construct the guitar's neck. This guarantees that the instrument possesses the necessary strength and durability to endure the tension of the steel strings. Moreover, steel billets can also be employed in the production of other metal instruments such as drums or percussion instruments, where their strength and resilience offer advantages. Nevertheless, it is important to acknowledge that the utilization of steel billets may vary depending on the specific instrument and its manufacturing process.

- Q: What are the different surface defects found in alloy steel billets?

- There are several different surface defects that can be found in alloy steel billets. These defects can occur during the production process and can have an impact on the quality and performance of the final product. Some of the common surface defects found in alloy steel billets include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of the billet during the heating and cooling process. It can be caused by exposure to air or by the presence of impurities in the steel. Scale can negatively affect the surface finish and can also lead to corrosion. 2. Cracks: Cracks can occur on the surface of the billet due to various reasons such as improper cooling, excessive stress, or improper handling. These cracks can weaken the structural integrity of the billet and can lead to failure during subsequent processing or in the final product. 3. Pits: Pits are small depressions or cavities that can be found on the surface of the billet. They can be caused by the presence of impurities or by the reaction of the steel with the environment. Pits can affect the surface finish and can also act as stress concentration points, leading to further damage or failure. 4. Laminations: Laminations are layers or sheets of non-metallic material that can be found within the billet. They can occur due to incomplete bonding during the production process or due to the presence of impurities in the steel. Laminations can weaken the billet and can lead to failure under load. 5. Inclusions: Inclusions are non-metallic particles or impurities that can be found within the steel. They can be introduced during the production process or can be present in the raw materials. Inclusions can affect the mechanical properties of the steel and can lead to reduced strength, toughness, and ductility. 6. Decarburization: Decarburization is the loss of carbon from the surface of the steel. It can occur during the heating process or due to exposure to air. Decarburization can result in reduced hardness and strength in the affected area. It is important to detect and address these surface defects in alloy steel billets to ensure the production of high-quality and reliable products. Various inspection and testing methods, such as visual inspection, ultrasonic testing, and magnetic particle inspection, can be employed to identify and assess these defects.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 135mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords