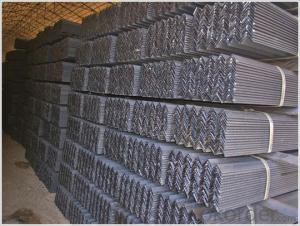

Hot Rolled Steel Angle Bar with High Quality 65*65mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 65*65*5 | 4.907 | 65*65*8 | 7.662 |

| 65*65*6 | 5.841 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used in solar panel mounting systems?

- Yes, steel angles can be used in solar panel mounting systems. Steel angles are commonly used due to their strength and durability, providing a stable and secure base for solar panels. They can be easily adjusted and customized to fit various installation requirements, making them a popular choice in solar panel mounting systems.

- Q: How are steel angles cut to specific lengths?

- Steel angles are cut to specific lengths using various cutting tools and techniques. One common method is using a saw, such as a band saw or a circular saw with a metal-cutting blade. The angle is securely clamped or held in place, and the saw blade is guided along the desired cutting line to make a clean and precise cut. Another method is using an abrasive cutting wheel, also known as a cutoff wheel or a grinding disc. This technique is often used for thinner steel angles or when a more precise cut is required. The angle is secured in a vise or a similar holding device, and the cutting wheel is carefully guided along the marked cutting line to remove the excess material. For larger and thicker steel angles, a plasma cutter or an oxy-fuel torch may be used. Both methods involve heating the steel to a high temperature, causing it to melt or oxidize, allowing for a clean and accurate cut. Plasma cutters use a focused jet of ionized gas, while oxy-fuel torches rely on a combination of oxygen and a fuel gas, such as acetylene or propane. In some cases, steel angles can also be cut using more specialized techniques, such as water jet cutting or laser cutting. Water jet cutting involves using a high-pressure stream of water mixed with abrasive particles to erode the steel, while laser cutting utilizes a concentrated laser beam to melt or vaporize the material along the desired cutting path. Regardless of the method used, the key is to ensure the angle is securely held in place and the cutting tool is guided accurately along the marked cutting line. Proper safety precautions, such as wearing protective eyewear and gloves, should always be taken when cutting steel angles to specific lengths.

- Q: How do steel angles perform in terms of electrical conductivity?

- Because steel angles are made of steel, their electrical conductivity is typically poor. Steel, compared to materials like copper or aluminum, is a poor conductor of electricity. This is because the steel material has high resistance, which hinders the flow of electrons. As a result, steel angles are not frequently utilized in electrical applications that necessitate good electrical conductivity. Nevertheless, steel angles can still find utility in specific electrical applications where conductivity is not a crucial factor, such as offering structural support in electrical installations.

- Q: Are steel angles suitable for rooftop installations?

- Indeed, rooftop installations can indeed benefit from the suitability of steel angles. Steel angles are frequently employed in construction endeavors due to their impressive strength and durability. Their capacity to furnish structural support and stability renders them especially advantageous for rooftop installations. Solar panels, HVAC units, communication antennas, and satellite dishes can all be effectively secured using steel angles. Furthermore, steel angles boast resistance against weathering, corrosion, and fire, thus solidifying their reputation as a dependable option for rooftop installations.

- Q: How are steel angles used in construction?

- Steel angles are commonly used in construction for a variety of purposes. One of the main uses of steel angles is to provide structural support and reinforcement in buildings and other structures. They are often used to create strong and stable connections between different components, such as beams, columns, and trusses. Steel angles are typically used to form the framework of a structure, providing stability and strength. They can be used to form corners, support beams, and brace walls. Steel angles are also frequently used to create lintels, which are horizontal supports placed above doors and windows to distribute the weight of the structure and prevent sagging. In addition to their structural uses, steel angles can also be used for aesthetic purposes in construction. They can be used to create decorative edging or trim, adding visual appeal to a building. Steel angles can also be used to create staircases, handrails, and other architectural features. Overall, steel angles are versatile and essential components in construction. They provide structural support, reinforcement, and aesthetic elements to ensure the durability, stability, and visual appeal of buildings and other structures.

- Q: What is 4# angle iron? What are the classifications of angle iron? What are the specifications? Thank you

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame and warehouse.

- Q: What does "angle length" and "limb width" mean?

- The width of a limb refers to the width of the point to the edge of the angle, and the length of the limb corresponds to the length of the edge;Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q: Are steel angles suitable for manufacturing structural beams?

- Yes, steel angles are suitable for manufacturing structural beams. Steel angles, also known as L-shaped structural steel, are commonly used in the construction industry to create structural beams due to their strength and versatility. Steel angles offer excellent load-bearing capabilities and are able to withstand heavy loads and forces, making them ideal for constructing beams that can support the weight of buildings, bridges, and other structures. Additionally, steel angles can be easily welded, bolted, or otherwise connected to form larger structural components, providing flexibility in design and construction. Overall, steel angles are a reliable and efficient choice for manufacturing structural beams.

- Q: Are steel angles suitable for coastal or saltwater environments?

- Yes, steel angles are suitable for coastal or saltwater environments. They are widely used in various marine applications due to their excellent corrosion resistance properties. The alloying elements in steel angles, such as chromium and nickel, help to protect against rust and corrosion caused by exposure to saltwater or high humidity. Additionally, proper maintenance and coatings can further enhance their durability in these environments.

- Q: Can steel angles be used as bracing elements in buildings?

- Yes, steel angles can be used as bracing elements in buildings. Steel angles are commonly used in construction for their strength and versatility. They are often used as structural components to provide lateral stability and support to buildings. Steel angles can be used as bracing elements to resist horizontal loads such as wind or seismic forces, helping to prevent excessive movement or deformation of the structure. They are typically installed at strategic locations, such as corners or intersections, and can be connected to other structural members using bolts or welds. Steel angles are preferred for bracing due to their high strength-to-weight ratio, durability, and ease of installation. Overall, steel angles are a reliable and commonly used solution for bracing elements in buildings.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 65*65mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords