ASTM -A36 Hot Rolled H-Section Steel Column

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

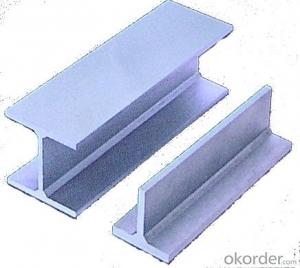

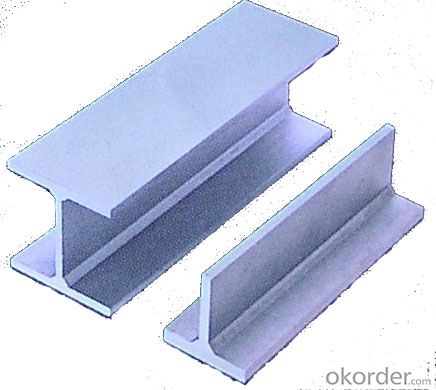

ASTM -A36 Hot Rolled H-Section Steel Column

Quick Details

Place of Origin: | China (Mainland) | Grade: | ASTM -A36 | Technique: | Hot Rolled |

Thickness: | 4mm - 16mm | Application: | decoration,kitchen,building,medical treatment,transport,chemical indus | Length: | 12 m |

Standard: | GB JIS | Flange Width: | 100--500mm | Flange Thickness: | 8--70mm |

Web Width: | 100--1000mm | Web Thickness: | 5--40mm | ||

Model Number: | H section steel ASTM -A36 | Exported Area | USA,Europe,Asia,Middle East,Africa,South America |

Application

decoration,kitchen,building,medical treatment,transport,chemical indus

Specifications

We are professional supplier and exporter of H beam.

Size:100*50*5*7mm - 700*300*13*24mm

Specification

Model Table in mm

100×50×5×7 | 200×204×12×12 | 338×351×13×13 | 482×300×11×15 |

100×100×6×8 | 244×175×7×11 | 340×250×9×14 | 488×300×11×18 |

125×60×6×8 | 244×252×11×11 | 350×175×7×11 | 496×199×9×14 |

125×125×6.5×9 | 248×124×5×8 | 350×350×12×19 | 500×200×10×16 |

148×100×6×9 | 250×125×6×9 | 360×250×12×19 | 582×300×12×17 |

150×75×5×7 | 250×250×9×14 | 360×350×12×19 | 588×300×12×20 |

150×100×6×9 | 250×255×14×14 | 390×300×10×16 | 594×302×12×20 |

150×150×7×10 | 294×200×8×12 | 396×199×7×11 | 600×200×11×17 |

175×90×5×8 | 294×302×12×12 | 400×200×8×13 | 600×300×12×20 |

175×175×7.5×11 | 298×201×9×14 | 400×400×13×21 | 700×300×13×24 |

194×150×6×9 | 300×150×6.5×9 | 414×405×18×28 | 800×300×14×26 |

200×100×5.5×8 | 300×200×8×12 | 440×300×11×18 | 900×500×16×28 |

200×150×6×9 | 300×300×10×15 | 450×200×9×14 | |

200×200×8×12 | 300×305×15×15 | 450×300×11×18 |

Pictures

- Q: What is the theoretical weight of welded H - section steel 900*350*20*30?

- 298*149*12*16 is the welding specification, the weight is 63.4KG per meter.

- Q: How do you calculate the moment of inertia for steel H-beams?

- To calculate the moment of inertia for steel H-beams, you need to consider the geometry of the beam and its cross-sectional shape. The moment of inertia, denoted as I, measures an object's resistance to changes in its rotational motion. For an H-beam, the moment of inertia calculation involves breaking down the beam into individual components and calculating the moment of inertia for each component. The H-beam consists of a web and two flanges connected together. To calculate the moment of inertia for the web component, you need to determine the dimensions of the web, such as the height (h) and the thickness (tw). You can then use the formula for the moment of inertia for a rectangle, I = (1/12) * b * h^3, where b is the width of the web. For the flange components, you need to determine the dimensions of each flange, such as the width (bf), the height (tf), and the distance from the centroid of the flange to the neutral axis (c). The moment of inertia for each flange can be calculated using the formula, I = (1/12) * bf * tf^3 + bf * tf * c^2. Once you have calculated the moment of inertia for each component (web and flanges), you can sum them up to find the total moment of inertia for the steel H-beam. The equation for the total moment of inertia is I = Iweb + 2 * Iflange. It is important to note that the moment of inertia calculation assumes that the steel H-beam is a homogeneous material and that there are no cutouts or holes in the beam. Additionally, the accuracy of the calculation depends on the accuracy of the dimensions used. It is always recommended to consult engineering references or design specifications for accurate moment of inertia values for specific H-beam sizes and configurations.

- Q: How do steel H-beams perform in high-traffic areas such as airports or train stations?

- Steel H-beams are an ideal choice for high-traffic areas such as airports or train stations due to their exceptional performance characteristics. Firstly, steel H-beams offer superior structural strength and stability, which is crucial in areas with heavy foot traffic and constant movement of vehicles. They can support heavy loads without bending or warping, ensuring the safety and longevity of the structure. Moreover, steel H-beams have excellent resistance to wear and tear. In high-traffic areas, frequent contact with luggage carts, trolleys, and other heavy equipment can cause significant damage to the infrastructure. However, steel H-beams are highly durable and can withstand this constant impact without compromising their structural integrity. Additionally, steel H-beams are known for their fire resistance. Airports and train stations are public spaces where fire safety is of utmost importance. Steel is a non-combustible material, and H-beams have a high melting point, which means they have a better chance of withstanding fire accidents and minimizing the spread of flames, providing added safety for occupants. Furthermore, steel H-beams are highly customizable, allowing for efficient design and construction in high-traffic areas. They can be fabricated to various lengths, sizes, and shapes, ensuring the structural requirements of the specific location are met. This versatility enables architects and engineers to create innovative and efficient designs that optimize space and accommodate the needs of the area. In terms of maintenance, steel H-beams have a low maintenance requirement, making them cost-effective in the long run. With regular inspections and minimal repairs, steel H-beams can maintain their structural integrity and appearance for many years, even in high-traffic areas. Overall, steel H-beams are the preferred choice for high-traffic areas such as airports or train stations due to their exceptional strength, durability, fire resistance, and customization options. Their performance characteristics make them capable of withstanding heavy loads, resisting wear and tear, and ensuring the safety and longevity of the infrastructure in these bustling public spaces.

- Q: Are all the steel girders H?

- H steel, I-beam and channel steel are possible

- Q: How are steel H-beams transported and handled on construction sites?

- Steel H-beams are typically transported and handled on construction sites using heavy machinery and equipment. The transportation process begins with loading the H-beams onto trucks or trailers, usually using cranes or forklifts. It is important to ensure that the H-beams are properly secured during transportation to prevent any damage or accidents. Once the steel H-beams arrive at the construction site, they are unloaded from the trucks or trailers, again using cranes or forklifts. The H-beams are then moved to the designated area where they will be used in the construction process. Handling steel H-beams requires careful planning and coordination. The beams are often quite heavy and bulky, so it is crucial to have the necessary equipment and machinery to lift and maneuver them safely. Cranes are commonly used to lift the H-beams and position them into place. These cranes are often operated by trained professionals who have expertise in handling heavy loads. In some cases, steel H-beams may need to be cut or modified on site to fit specific requirements. This is typically done using specialized cutting and welding equipment. It is important to follow proper safety procedures and guidelines when performing these tasks to ensure the integrity of the H-beams and the safety of the workers. Overall, transporting and handling steel H-beams on construction sites requires careful planning, coordination, and the use of appropriate machinery and equipment. Safety should always be the top priority to prevent accidents and ensure the successful completion of the construction project.

- Q: What are the different sizes of steel H-beams available?

- To cater to diverse construction and engineering requirements, a range of steel H-beams, also known as wide flange beams, is offered in various sizes. The dimensions of these H-beams, including height, width, and weight per foot, typically determine their sizes. Take a look at the following commonly used steel H-beam sizes: 1. Standard H-beams: These H-beams, which adhere to the standards set by the American Society for Testing and Materials (ASTM), are widely utilized. They come in different sizes, with heights ranging from 3 inches to 24 inches and widths ranging from 3 inches to 12 inches. The weight per foot of standard H-beams varies depending on the specific size and steel grade employed. 2. Wide flange beams: Also referred to as W-beams, wide flange beams possess wider flanges in comparison to standard H-beams. These flanges are designed to distribute loads over a larger area, making them suitable for applications demanding higher load-bearing capacity. Wide flange beams are available in heights ranging from 4 inches to 44 inches and widths ranging from 4 inches to 16 inches. 3. European standard beams: Apart from the American standard sizes, European standard beams are designated based on their height in millimeters. These beams are commonly used in Europe and encompass heights ranging from 80 mm to 750 mm. 4. Specialized H-beams: In addition to standard and European sizes, specialized H-beams are also available for specific applications. Heavy-duty H-beams find application in industries and structural projects, while lightweight H-beams are commonly used in residential construction and smaller-scale endeavors. It is crucial to note that the availability of different sizes may vary depending on the supplier or manufacturer. When selecting steel H-beams for a project, it is advisable to seek guidance from a structural engineer or supplier who can recommend the appropriate size and grade of H-beams for the specific application.

- Q: How do you calculate the deflection limits for steel H-beams?

- To calculate the deflection limits for steel H-beams, you typically refer to the relevant design codes and standards. These codes provide specific formulas and criteria to determine the maximum allowable deflection based on factors such as the beam's span, load conditions, and the desired level of performance. The deflection limits are calculated using equations that account for beam properties, loading conditions, and safety factors to ensure structural integrity and prevent excessive deflection.

- Q: How do steel H-beams perform in areas with high humidity?

- Steel H-beams are renowned for their remarkable strength and durability, making them a favored option for diverse construction projects. In terms of regions with elevated humidity levels, steel H-beams exhibit exceptional performance. One of the primary merits of steel lies in its ability to resist moisture and corrosion. Usually, steel H-beams are coated with protective finishes or galvanized to enhance their resistance against rust and corrosion. These coatings function as a barrier, preventing moisture from infiltrating the beam's surface and causing harm. High humidity can result in the accumulation of moisture in the atmosphere, which may potentially inflict structural damage on specific materials. However, steel H-beams are immune to this issue. Their sturdy construction and corrosion-resistant coatings ensure their ability to withstand the challenges posed by humid environments. Furthermore, steel H-beams possess excellent load-bearing capabilities, which are vital for areas characterized by high humidity. Moisture in the atmosphere can sometimes weaken certain materials, compromising their structural integrity. Nonetheless, steel H-beams retain their strength and stability, even in humid conditions. It is important to note that regular maintenance and inspections are still necessary to ensure the long-term performance of steel H-beams in high humidity areas. This includes conducting routine checks for any signs of corrosion or damage to the protective coatings. By promptly addressing any emerging issues, the lifespan and performance of the steel H-beams can be maximized. In conclusion, steel H-beams are a dependable choice for areas with high humidity due to their resistance to moisture, corrosion, and their excellent load-bearing capabilities. With proper maintenance, these beams can provide enduring structural support, even in challenging environmental conditions.

- Q: Can Steel H-Beams be used in school or educational building construction?

- Indeed, in school or educational building construction, Steel H-Beams find utility. Their strength and durability make them a frequent choice in construction projects. They offer dependable structural support for extensive spans and hefty loads, rendering them appropriate for the construction of educational facilities like schools and universities. These beams serve various functions, such as roof support, open floor plan creation, or the construction of substantial structures like gymnasiums or auditoriums. Moreover, Steel H-Beams can be effortlessly fabricated and installed, thus proving to be cost-effective and efficient in the realm of educational building construction.

- Q: Are steel H-beams recyclable?

- Indeed, steel H-beams possess recyclability. Steel, widely recognized as one of the most frequently recycled materials worldwide, extends its recyclability to H-beams. Once steel H-beams have fulfilled their purpose or become superfluous, they can be gathered, processed, and subsequently melted to form fresh steel commodities. This recycling procedure entails shredding the H-beams into smaller fragments, eliminating any impurities, and melting the steel through a furnace. Once liquefied, the steel can be employed in the creation of an extensive array of novel products, including fresh H-beams. By recycling steel H-beams, not only do we contribute to the preservation of natural resources, but we also diminish the environmental repercussions linked to mining and manufacturing new steel.

Send your message to us

ASTM -A36 Hot Rolled H-Section Steel Column

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords