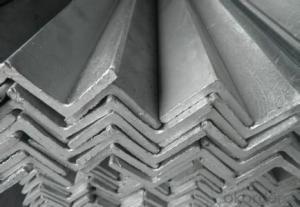

Equal Angle Steel Hot Rolled ASTM A36 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||

a*t | ||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel angles be galvanized or coated for additional protection?

- Indeed, steel angles can be galvanized or coated to enhance their protection. Galvanization is a widely used technique for safeguarding steel against corrosion. It entails applying a layer of zinc onto the steel, which acts as a barrier against moisture and other corrosive elements. This process can be accomplished through hot-dip galvanization, where the steel angle is immersed in a bath of molten zinc, or through electroplating, which involves applying a thin layer of zinc to the steel surface using an electric current. Furthermore, coating steel angles with alternative protective materials is a viable option. There are several coating choices available, including epoxy, powder coatings, and paint. These coatings establish a protective layer on the steel's surface, shielding it from environmental factors that may cause corrosion or damage. By applying galvanization or coatings to steel angles, additional protection is provided, thereby extending the material's lifespan and ensuring its durability in various applications and environments.

- Q: What are the different tolerances for steel angles?

- The different tolerances for steel angles can vary depending on the specific industry standards and requirements. Generally, tolerances for steel angles may include measurements for dimensions such as length, width, thickness, and straightness. These tolerances ensure that the steel angles meet the desired specifications and can be properly utilized in various applications.

- Q: Can steel angles be used as bracing elements?

- Yes, steel angles can be used as bracing elements. Steel angles are often used in construction as bracing elements due to their strength and stability. They can effectively provide support and enhance the structural integrity of a building or structure.

- Q: Are steel angles available in different grades of steel?

- Different grades of steel are available for steel angles, which are widely used in the construction and manufacturing industries for various purposes including structural support, framing, and bracing. The grade of steel used in steel angles is determined based on its chemical composition, mechanical properties, and intended use. A36, A572, and A588 are some common grades of steel used for steel angles, each with specific characteristics suited for different applications. For instance, A36 steel angles are commonly utilized for general structural purposes, whereas A572 steel angles possess higher strength and are often utilized in heavy-duty construction projects. The selection of the grade depends on factors like load-bearing capacity, corrosion resistance, and cost considerations.

- Q: What is the maximum length for a curved steel angle?

- Several factors, such as the diameter of the curve, the steel thickness, and the project's specific requirements, determine the maximum length of a curved steel angle. Typically, the length can range from a few inches to several feet. However, it is crucial to seek guidance from a structural engineer or manufacturer to ensure the angle's structural integrity is not compromised. The manufacturing process and available equipment may also influence the achievable maximum length for a curved steel angle.

- Q: How are steel angles protected against atmospheric corrosion?

- Steel angles are protected against atmospheric corrosion through a variety of methods. One common method is by applying a protective coating, such as paint, to the surface of the steel angles. This coating acts as a barrier between the steel and the surrounding atmosphere, preventing the steel from coming into direct contact with moisture or oxygen, which are the main contributors to corrosion. Another method of protection is through galvanization. Galvanization involves coating the steel angles with a layer of zinc, either through hot-dip galvanization or electroplating. The zinc acts as a sacrificial layer, corroding in place of the steel. This sacrificial corrosion process helps to protect the steel angles from atmospheric corrosion. In addition to coatings, steel angles can also be protected through the use of inhibitors. Inhibitors are substances that are added to the surrounding environment or applied directly to the steel surface to slow down or prevent corrosion. These inhibitors work by either forming a protective film on the steel surface or by altering the chemical environment to make it less corrosive. Regular maintenance and inspection are also essential in protecting steel angles against atmospheric corrosion. This includes cleaning the surface of the steel angles to remove any dirt or debris that may trap moisture and accelerate corrosion. It is also important to promptly repair any damaged or deteriorated coatings to ensure continued protection against corrosion. Overall, a combination of protective coatings, galvanization, inhibitors, and regular maintenance is necessary to effectively protect steel angles against atmospheric corrosion and extend their lifespan.

- Q: Can steel angles be used for sign posts?

- Certainly! Sign posts can indeed utilize steel angles. Due to their robustness and endurance, steel angles are frequently employed in construction. They can effectively offer the required support and stability for sign posts, particularly in regions prone to strong winds or heavy traffic. Moreover, the versatility of steel angles shines through as they can be effortlessly welded or bolted together, presenting an adaptable choice for sign post installation. Furthermore, their immunity to corrosion guarantees a lengthier lifespan, thereby diminishing expenses associated with maintenance and replacement.

- Q: What are the common shapes and dimensions of steel angles?

- The common shapes of steel angles include equal angles, unequal angles, and L-shaped angles. The dimensions of these angles can vary widely, but some common sizes include 1/2 inch, 3/4 inch, 1 inch, 1-1/2 inch, and 2 inches. The thickness or gauge of the angles can also differ, typically ranging from 1/8 inch to 1/4 inch.

- Q: What are the different standards for steel angles?

- Steel angles, commonly used in construction and industrial applications, adhere to various standards to meet specific requirements. The American Society for Testing and Materials (ASTM) standard, specifically ASTM A36, is widely recognized and specifies the chemical composition, mechanical properties, and tolerances of steel angles. This standard is suitable for general structural purposes and is available in different sizes and lengths. Similarly, the European standard, known as EN 10025, encompasses multiple grades of steel angles, including S235, S275, and S355, which correspond to different yield strengths. These angles find extensive use in construction, machinery, and engineering industries throughout Europe. Country-specific standards also exist, such as the Japanese Industrial Standards (JIS) and the British Standards (BS). JIS G3101, a renowned standard in Japan, outlines the specifications for hot-rolled steel angles used in general structures. Meanwhile, BS EN 10056, a British standard, provides specifications for steel angles employed in construction. Furthermore, specialized standards cater to specific applications, such as marine-grade steel angles that withstand corrosion in saltwater environments. These standards, like ASTM A588, impose additional requirements for chemical composition and mechanical properties to ensure durability in harsh conditions. In conclusion, the diversity of steel angle standards guarantees that these structural shapes fulfill precise requirements regarding strength, durability, and compatibility with various construction and industrial applications. To ensure compliance with necessary specifications, it is crucial to consult the appropriate standard when selecting steel angles.

- Q: Can steel angles be galvanized?

- Indeed, galvanizing is a feasible option for steel angles. Galvanization entails the application of a safeguarding zinc coating onto steel to inhibit rust and corrosion. To galvanize steel angles, one can either immerse them in a heated bath of molten zinc or employ a specialized spray or paint technique for zinc application. Galvanized steel angles find widespread use in the realms of construction, manufacturing, and outdoor settings, where defense against rust and corrosion is imperative.

Send your message to us

Equal Angle Steel Hot Rolled ASTM A36 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords