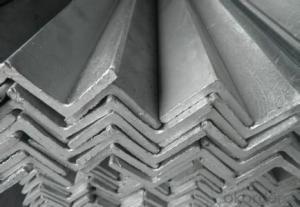

Angle Steel Hot Rolled High Quality ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel Hot Rolled High Quality ASTM A36 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel Angle Steel Hot Rolled High Quality ASTM A36 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1:Would you please tell me the length of angle steel?

A1: 6m and 12m is OK for us.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel angles be painted over?

- Indeed, painting over steel angles is possible. To ensure a successful outcome, it is vital to first guarantee that the surface is thoroughly cleansed and devoid of any dirt, oil, or rust. Accomplishing this can be done by utilizing a wire brush or sandpaper to eliminate any loose particles, followed by wiping the surface with a clean cloth. Once the surface is adequately prepared, it is necessary to apply a specialized primer created for metal surfaces in order to enhance adhesion and prevent corrosion. After the primer has dried, a suitable paint can be administered using a brush, roller, or spray gun. It is advisable to select paints specifically formulated for metal applications to ensure proper adhesion and durability. Over time, routine maintenance and repainting may be necessary to uphold the appearance and safeguard the steel angles from corrosion.

- Q: Can steel angles be cut to size?

- Certainly! Steel angles are capable of being cut to the desired size. These versatile structural materials, commonly referred to as L-shaped angles, find extensive use in the construction and manufacturing sectors. One can effortlessly tailor their length using a variety of cutting tools such as saws, plasma cutters, or angle grinders. This enables customization and guarantees a seamless fit for the steel angles in their intended purpose. It is crucial to adhere to suitable safety precautions and utilize appropriate equipment while cutting these angles, given their formidable strength and durability.

- Q: How do steel angles compare to aluminum angles in terms of strength and durability?

- Compared to aluminum angles, steel angles exhibit superior strength and durability. This is attributed to steel's higher tensile strength and yield strength, enabling it to endure higher levels of force and pressure without warping or fracturing. Moreover, steel boasts better resistance against corrosion, ensuring its structural integrity remains intact for extended durations. In contrast, aluminum is prone to oxidation and may gradually weaken over time. Consequently, when seeking high strength and long-lasting robustness, steel angles emerge as the more favorable option over aluminum angles.

- Q: What are the different grades of steel used for manufacturing steel angles?

- There are several different grades of steel that are commonly used for manufacturing steel angles. These include: 1. Mild Steel: This is the most common grade of steel used for manufacturing steel angles. It has a low carbon content and is relatively inexpensive. Mild steel angles are suitable for a wide range of applications and have good weldability and formability. 2. High-strength low-alloy (HSLA) steel: This grade of steel contains small amounts of alloying elements such as copper, vanadium, or niobium, which enhance its strength and toughness. HSLA steel angles are commonly used in structural applications where high strength and durability are required. 3. Stainless Steel: Stainless steel angles are manufactured using alloys that contain a high percentage of chromium, which provides excellent corrosion resistance. These angles are commonly used in environments where corrosion is a concern, such as coastal areas or chemical plants. 4. Carbon Steel: Carbon steel angles are made from a combination of iron and carbon, with carbon content typically ranging from 0.05% to 2.1%. The higher the carbon content, the stronger and harder the steel. Carbon steel angles are commonly used in construction and machinery manufacturing. 5. Alloy Steel: Alloy steel angles are made by adding various alloying elements such as manganese, nickel, chromium, or molybdenum to carbon steel. These additions improve the strength, hardness, and resistance to wear and corrosion of the steel. Alloy steel angles are commonly used in heavy-duty applications such as mining equipment or industrial machinery. The choice of grade of steel for manufacturing steel angles depends on the specific requirements of the application, including the desired strength, durability, corrosion resistance, and cost.

- Q: What are the different types of connections used for steel angles in educational institutions?

- In educational institutions, there are several types of connections used for steel angles. These connections serve to join steel angles together in various applications and structural configurations. Some of the common types of connections used are: 1. Welded Connections: Welding is a widely used method to connect steel angles in educational institutions. It involves melting and fusing the steel angles together using heat, creating a strong and durable connection. Welded connections are often used in structural applications where high strength and rigidity are required. 2. Bolted Connections: Bolted connections involve using bolts, nuts, and washers to secure steel angles together. This type of connection allows for easy disassembly and reassembly, making it suitable for applications where flexibility and adjustability are desired. Bolted connections are commonly used in non-structural applications like furniture, handrails, and brackets. 3. Riveted Connections: Riveting is an older method of connection, where steel angles are joined using rivets. Rivets are inserted through pre-drilled holes in the angles and then hammered or compressed to secure the connection. Although not as commonly used today, riveted connections can still be found in some older structures within educational institutions. 4. Clip Connections: Clip connections involve using specially designed clips or brackets to connect steel angles together. These clips are typically bolted or welded to the angles, providing a quick and efficient method of connection. Clip connections are often used in applications where easy installation and maintenance are important, such as suspended ceilings or modular structures. 5. Gusset Plate Connections: Gusset plate connections involve using additional steel plates (gusset plates) to connect steel angles. The gusset plates are typically welded or bolted to the angles, providing additional strength and stability to the connection. This type of connection is commonly used in heavy-duty structural applications, such as trusses or frames, within educational institutions. Overall, the selection of the type of connection for steel angles in educational institutions depends on factors such as the load requirements, structural design, ease of installation, and maintenance considerations. It is essential to consult with structural engineers and follow applicable building codes and regulations to ensure safe and appropriate connections are used.

- Q: Can steel angles be used as framing members in buildings?

- Framing members in buildings can indeed utilize steel angles. These angles are commonly employed in construction to serve as a structural element for framing, bracing, and supporting various components of a building. With their exceptional strength, durability, and load-bearing capacity, they prove suitable for a wide range of applications in building construction. Steel angles possess the ability to form rigid frames, trusses, and connections, thereby providing stability and support to the structure. Moreover, they can be easily welded, bolted, or connected using other fastening methods, allowing for flexible and efficient construction. In essence, steel angles present themselves as a versatile and dependable choice for framing members in buildings.

- Q: How do steel angles contribute to the overall earthquake resistance of a structure?

- Steel angles contribute to the overall earthquake resistance of a structure in several ways. First and foremost, steel angles are commonly used as reinforcement elements in the construction industry. When properly installed and anchored, they can help increase the overall strength and stability of a structure, making it more resistant to the lateral forces generated during an earthquake. Steel angles are often used to create moment-resisting frames, which are designed to absorb and distribute the seismic energy throughout the structure. These frames, made up of interconnected steel angles, provide a robust system that can effectively resist the horizontal forces exerted by an earthquake. By distributing the seismic load, steel angles help prevent concentrated stress points and potential failure of the structure. Moreover, steel angles can be strategically placed at key locations, such as corners, junctions, and openings, to enhance the overall stiffness and rigidity of the structure. This increased stiffness helps reduce the building's response to seismic vibrations and prevents excessive deformation, which could lead to structural damage. Additionally, steel angles can be used to create diagonal bracing systems, which are essential for mitigating the effects of seismic forces. These systems consist of interconnected steel angles diagonally placed within the structure, forming a network that improves the building's ability to withstand lateral loads. Diagonal bracing effectively dissipates earthquake energy and redirects it away from critical components, thus enhancing the structure's overall earthquake resistance. In summary, steel angles play a crucial role in enhancing the earthquake resistance of a structure. They provide reinforcement, create moment-resisting frames, increase stiffness, and enable the installation of diagonal bracing systems, all of which contribute to the structural integrity and resilience of a building during seismic events.

- Q: Are steel angles suitable for high-temperature applications?

- No, steel angles are not suitable for high-temperature applications. Steel angles are typically made from carbon steel, which starts to lose its strength and structural integrity at elevated temperatures. At high temperatures, carbon steel undergoes a process called thermal expansion, where it expands and becomes weaker. This can lead to deformations and structural failures in the steel angles. For high-temperature applications, materials such as stainless steel or alloys with higher heat resistance, such as Inconel or Hastelloy, are more suitable. These materials can withstand higher temperatures without significant loss of strength and structural stability.

- Q: Can steel angles be used in industrial or heavy-duty applications?

- Yes, steel angles can definitely be used in industrial or heavy-duty applications. Steel angles are known for their strength, durability, and versatility, making them suitable for a wide range of applications in various industries. They provide structural support, reinforcement, and stability in heavy-duty machinery, equipment, and infrastructure projects. Steel angles are commonly used in construction, manufacturing, engineering, and transportation industries, among others. They can be employed in applications such as frames, supports, bracings, platforms, beams, and trusses, where strength and load-bearing capabilities are crucial. Additionally, steel angles can withstand high temperatures, extreme weather conditions, and heavy loads, making them suitable for challenging industrial environments. Overall, steel angles are a reliable and efficient choice for industrial or heavy-duty applications due to their strength, durability, and adaptability.

- Q: What are the common loadings or forces that steel angles are designed to withstand?

- Steel angles are commonly used in various structural applications due to their versatility and strength. These angles are designed to withstand a variety of loadings or forces, depending on the specific application. Some common loadings that steel angles are designed to withstand include: 1. Compression: Steel angles can resist compressive forces, which are forces that tend to squeeze or compress the material. They are often used in columns or supports to bear the weight of a structure or to resist crushing loads. 2. Tension: Steel angles can also withstand tensile forces, which are forces that pull or stretch the material. They are often used in tension members, such as roof trusses or bridge supports, to resist pulling or stretching loads. 3. Bending: Steel angles are designed to resist bending forces, which occur when a material is subjected to a combination of tension and compression. They are commonly used in beams or braces to provide structural stability and prevent excessive deflection or bending. 4. Shear: Steel angles can withstand shear forces, which occur when one section of a material is pushed in one direction and another section is pushed in the opposite direction. They are often used in connections or joints to transfer loads between structural members and resist shearing forces. 5. Lateral loads: Steel angles are also designed to withstand lateral loads, which are forces that act horizontally on a structure. These loads can be caused by wind, earthquakes, or other external factors. Steel angles are often used in bracing systems to provide lateral stability and prevent the structure from overturning or collapsing. It is important to note that the specific loadings and forces that steel angles are designed to withstand may vary depending on the size, shape, and grade of the angle, as well as the specific design requirements of the application. Therefore, it is crucial to consult the appropriate design codes and engineering guidelines to ensure the proper selection and application of steel angles in a given structural design.

Send your message to us

Angle Steel Hot Rolled High Quality ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords