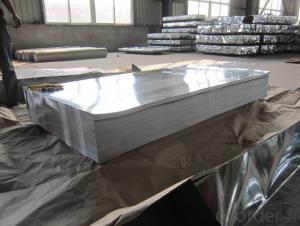

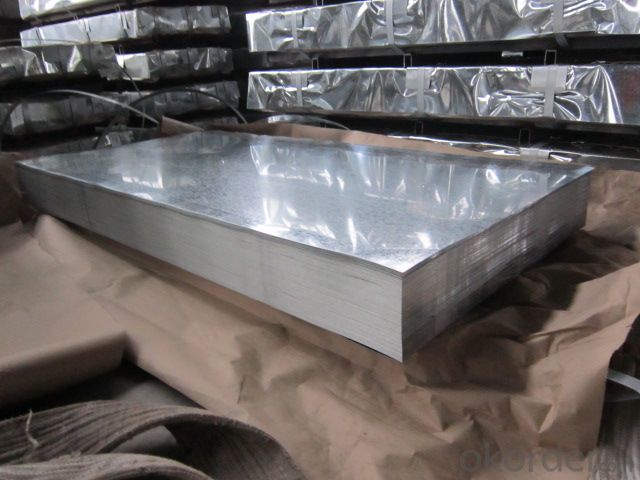

Hot-dip Galvanized Steel Sheets in Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

Application:

Construction, packaging, railway vehicles, agricultural machinery and daily life.

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.0mm

Width:600mm-1250mm

Length:1000mm-11800mm or as request

Package:3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made of iron and carbon, with trace amounts of other elements. It is susceptible to rust and corrosion, requiring regular maintenance and protection. On the other hand, stainless steel sheet is an alloy of iron, carbon, and chromium, with additional elements like nickel and molybdenum. It has a higher resistance to rust and corrosion, making it suitable for applications in harsh environments. Stainless steel sheet also offers better strength and durability compared to plain carbon steel sheet.

- Q: Are the steel sheets resistant to graffiti or vandalism?

- Yes, steel sheets are highly resistant to graffiti or vandalism. Due to their robust and durable nature, steel sheets serve as a formidable deterrent against acts of vandalism or graffiti. The smooth surface of steel sheets makes it difficult for vandals to adhere spray paint or other graffiti materials, and even if they manage to apply it, the paint can be easily removed with proper cleaning techniques without leaving any trace. Additionally, steel sheets are highly resistant to scratching or etching, which further prevents any form of vandalism. Overall, choosing steel sheets for surfaces that are prone to graffiti or vandalism offers excellent protection and minimizes the need for costly repairs or repainting.

- Q: Can steel sheets be used for furniture manufacturing?

- Yes, steel sheets can be used for furniture manufacturing. Steel is a versatile material that offers strength, durability, and a sleek appearance, making it suitable for various furniture applications such as tables, chairs, cabinets, and shelves. Steel sheets can be shaped, welded, and finished to create contemporary and modern furniture designs.

- Q: What are the different types of steel sheets?

- There are various types of steel sheets available, including hot rolled steel sheets, cold rolled steel sheets, galvanized steel sheets, and stainless steel sheets.

- Q: How do steel sheets differ from steel plates?

- Steel sheets differ from steel plates in terms of thickness. Steel sheets are generally thinner and have a thickness of up to 6mm, while steel plates are thicker and have a thickness exceeding 6mm. Additionally, steel sheets are often used for decorative purposes, whereas steel plates are used for structural applications that require greater strength and durability.

- Q: Can steel sheets be used for metal fencing?

- Yes, steel sheets can be used for metal fencing. Steel sheets are commonly used in the construction of metal fences due to their durability, strength, and resistance to corrosion. They can be easily fabricated and installed to create a sturdy and secure fencing solution.

- Q: Where can steel sheets be purchased?

- There are numerous places where one can acquire steel sheets. Local hardware stores, home improvement centers, and metal supply companies are among the common choices. These places typically provide a variety of steel sheet sizes and thicknesses for customers to choose from. Furthermore, the convenience of buying steel sheets online should not be overlooked. Online retailers and e-commerce platforms offer a wider range of options and competitive prices. To ensure you get the most value for your money, it is crucial to compare prices, quality, and customer reviews before making a purchase.

- Q: Do steel sheets require any surface treatment before installation?

- Surface treatment is typically necessary for steel sheets before they are installed. This is because it improves the steel's durability and appearance, and also protects it from corrosion. The most common methods of surface treatment for steel sheets are galvanization, painting, and powder coating. Galvanization involves adding a zinc coating to the steel, which helps prevent rust and corrosion. On the other hand, painting and powder coating involve applying a protective layer of paint or powder to the steel surface. These surface treatments not only make the steel look better but also make it more resistant to environmental factors like moisture, chemicals, and UV radiation. Therefore, it is advisable to apply the appropriate surface treatment to steel sheets before installation in order to ensure their long-lasting performance.

- Q: How do steel sheets handle expansion and contraction?

- Steel sheets handle expansion and contraction by allowing enough flexibility to accommodate changes in temperature. This is achieved through the inherent ductility and elasticity of steel, which enables it to expand and contract without significant deformation or damage. Additionally, steel sheets may be designed with specific expansion joints or gaps to further accommodate thermal changes and prevent buckling or warping.

- Q: How do you prevent scratches or dents on steel sheets?

- One way to prevent scratches or dents on steel sheets is by handling them with care and using protective measures, such as wearing gloves and using padding or protective covers during transportation or storage. Additionally, ensuring a clean and debris-free work area and avoiding contact with sharp or rough surfaces can help minimize the risk of scratches or dents on steel sheets.

Send your message to us

Hot-dip Galvanized Steel Sheets in Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords