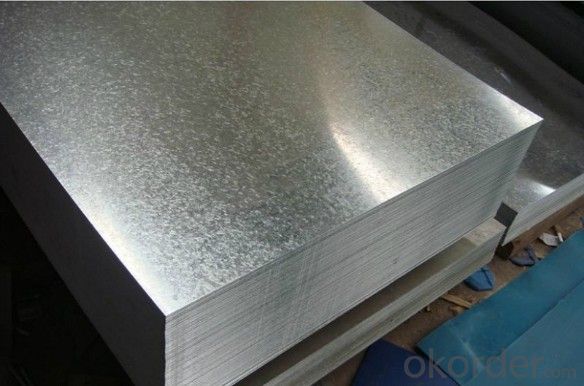

Prime Quality Hot Dipped Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil:

1. Thickness: 0.13mm-0.7mm

2. Width: 600mm-1250mm

3. Zinc Coating: 30-200g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry , chromated , non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data | |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips.

- Q: Can steel sheets be used for noise barriers?

- Indeed, noise barriers can indeed utilize steel sheets. Steel, being a resilient and sturdy substance, can effectively hinder or diminish the propagation of sound waves. Its substantial density and mass aid in the absorption and reflection of sound, thereby impeding its passage through the barrier. It is possible to tailor and produce steel sheets specifically for the purpose of noise reduction, incorporating attributes like perforations or acoustic insulation materials to enhance their efficacy. Moreover, steel sheets can be treated with coatings or paint to bolster their resistance against adverse weather conditions and corrosion. In general, steel sheets present a feasible choice for the construction of noise barriers, particularly in locales with elevated levels of noise pollution.

- Q: What are the safety precautions to consider when handling steel sheets?

- When handling steel sheets, some important safety precautions to consider include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against cuts, burns, and impact injuries. It is also important to ensure proper lifting techniques and the use of mechanical aids such as cranes or forklifts to avoid strain or back injuries. Additionally, maintaining a clean and organized workspace, properly storing steel sheets to prevent tripping hazards, and regularly inspecting equipment for any signs of damage or wear are crucial for maintaining a safe working environment.

- Q: What are the properties of steel sheets?

- Steel sheets have several advantageous properties, including high strength and durability, excellent corrosion resistance, good thermal conductivity, and the ability to be easily formed and welded.

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Cold rolled seamless steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube and other steel tube, including carbon thin-walled steel, alloy thin-walled steel, stainless steel, thin steel tube.

- Q: Are the steel sheets resistant to chemical spills?

- Yes, steel sheets are generally resistant to chemical spills. Steel is known for its durability and ability to withstand various environmental conditions, including exposure to chemicals. The non-reactive nature of steel makes it highly resistant to corrosion, which means it can effectively protect against chemical spills. However, the specific resistance of steel sheets to chemical spills may depend on the type and concentration of the chemicals involved. It is always recommended to consult with experts or refer to specific steel grades and their compatibility with different chemicals to ensure optimal resistance.

- Q: What is the process of applying insulation materials to steel sheets?

- The process of applying insulation materials to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepared to ensure proper adhesion of the insulation material. Then, a layer of adhesive is applied to the surface of the steel sheets. Next, the insulation material, such as foam or fiberglass, is cut and shaped to fit the dimensions of the steel sheets. The insulation material is then carefully placed onto the adhesive-coated steel sheets, ensuring proper alignment and coverage. Finally, the insulation material is pressed or secured in place to ensure a tight bond with the steel sheets.

- Q: What are the different sheet metal bending techniques for steel sheets?

- Steel sheets can be manipulated and shaped using various sheet metal bending techniques. These techniques help achieve desired forms and angles. Some commonly used techniques include: 1. V-bending: A V-shaped punch and die set are used to create a sharp bend in the steel sheet. The material is placed between the punch and die, and force is applied to form the desired angle. V-bending is versatile and can create different angles and shapes. 2. Air bending: In this technique, a punch presses the steel sheet into a V-shaped die without completely contacting the material. Bending is achieved by controlling the depth of penetration of the punch. Air bending allows for greater flexibility in angle adjustments and requires less force. 3. Edge bending: This technique involves bending the edge of the steel sheet to create flanges or edges with specific angles. The sheet is clamped between a punch and a die, and force is applied to bend the material along the edge. 4. Bottom bending: This technique is used to create larger bends in steel sheets. The sheet is clamped between a punch and a V-shaped die, and force is applied to bend the material around the die. Bottom bending is suitable for creating U-shaped parts or boxes. 5. Roll bending: Also known as cylindrical bending, this technique is used to create cylindrical or curved shapes in steel sheets. The sheet is passed through a set of rolls that gradually bend the material into the desired shape. Roll bending is commonly used in the production of pipes, tubes, and cylinders. 6. Coining: Coining is a precision bending technique that creates crisp, sharp bends. The steel sheet is pressed between a punch and a die, with the die featuring a sharp edge. High pressure is applied, resulting in a precise and defined bend. These are just a few of the many sheet metal bending techniques available for steel sheets. Each technique has its advantages and applications, and the choice of technique depends on factors such as the desired angle, sheet thickness, and shape complexity.

- Q: Can steel sheets be used for solar panel installations?

- Yes, steel sheets can be used for solar panel installations, particularly as a mounting structure or frame for the panels. Steel provides strength, durability, and stability, making it an ideal material for supporting solar panels and ensuring their long-term performance.

- Q: How are steel sheets protected against rusting?

- Steel sheets are protected against rusting through a process called corrosion protection. There are several methods used to protect steel sheets from rust, including: 1. Galvanization: This process involves coating the steel sheets with a layer of zinc. Zinc acts as a sacrificial anode, meaning it corrodes in place of the steel when exposed to moisture or oxygen. This creates a barrier that protects the steel from rusting. 2. Painting: Applying a layer of paint to steel sheets acts as a protective barrier against moisture and oxygen. The paint creates a physical barrier that prevents these elements from coming into contact with the steel, thus reducing the risk of rust formation. 3. Powder coating: Powder coating involves applying a dry powder to the steel sheets and then heating it to form a protective layer. The powder melts and fuses into a smooth coating, providing excellent resistance to rust and corrosion. 4. Electroplating: This method involves immersing the steel sheets in a bath containing a metal coating solution, such as zinc or chromium. An electric current is then passed through the bath, causing the metal coating to bond with the steel. This electroplated layer acts as a protective barrier against rust. 5. Phosphating: Phosphating is a chemical process where a layer of zinc or manganese phosphate is deposited on the steel sheets. This layer enhances the adhesion of paint or other coatings, providing a corrosion-resistant surface. These methods are commonly used in various industries to protect steel sheets from rusting. The specific method chosen depends on factors such as cost, durability requirements, and the environment in which the steel sheets will be used.

- Q: Steel plate pile length, adjacent two steel plate pile joints should be staggered what position?

- Hello, due to site transportation restrictions and insufficient length of existing materials and other reasonsSome projects need to meet the design length by using the site connection method.

Send your message to us

Prime Quality Hot Dipped Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords