HOT-DIP Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

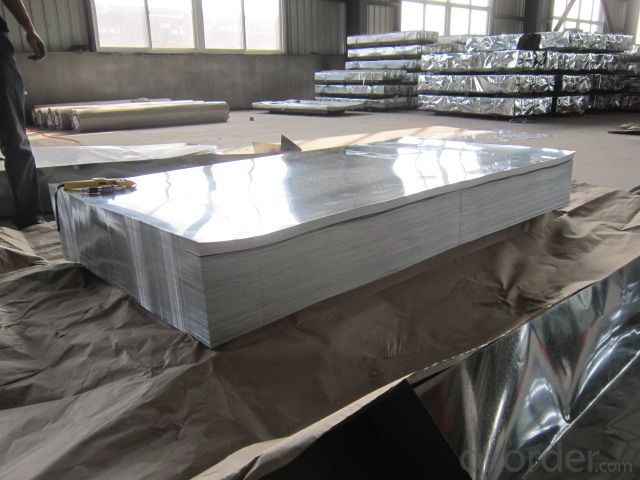

HOT-DIP Galvanized Steel Sheet

Application: with excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

Package:Standard seaworthy export packing: 3 layers of packing, inside is

kraft paper,water plastic film is in the middle and outside GI steel

sheet to be covered by steel strips with lock.

HOT-DIP GALVANIZED STEEL SHEETS

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

- Q: Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- Carbon steel according to the steel yield strength is divided into 5 grades: Q195, Q215, Q235, Q255 and Q275 of each grade because the quality is divided into A, B, C, D grade, with a maximum of four kinds, some only one; this is just plain carbon steel, the price is cheap, generally not heat treatment. Only quality carbon steel has the value of heat treatment.

- Q: Can steel sheets be used for making staircases?

- Staircases can indeed be made using steel sheets. Steel, being a robust and long-lasting material, is capable of withstanding significant weights, making it ideal for constructing staircases. By utilizing steel sheets, staircases are provided with a secure base and structural soundness, thereby guaranteeing both safety and durability. Moreover, steel allows for effortless shaping and molding into diverse designs, enabling a wide range of options for staircase aesthetics. Whether for residential, commercial, or industrial purposes, steel sheets are highly favored in the construction of staircases due to their exceptional strength, durability, and adaptability.

- Q: Can steel sheets withstand extreme temperatures?

- Indeed, extreme temperatures pose no challenge to steel sheets. Renowned for its remarkable melting point of approximately 1370°C (2500°F), steel proves itself as an ideal choice for environments characterized by intense heat, including furnaces, kilns, and industrial ovens. Moreover, steel exhibits exceptional thermal conductivity, enabling efficient heat transfer while effectively withstanding the expansion and contraction caused by temperature fluctuations. Thanks to these exceptional attributes, steel sheets remain impervious to warping, cracking, and other structural impairments often encountered in extreme temperature scenarios.

- Q: How is the normalized steel plate produced?

- Normalizing is the process of heating a steel member to 30-50 degrees above the critical temperature and cooling it in stationary air after proper heat preservation. This process is called normalizing.

- Q: What is the bending radius for steel sheets?

- The bending radius for steel sheets depends on various factors such as the thickness of the sheet, the type of steel being used, and the specific application. Generally, a common rule of thumb is to use a bending radius that is at least twice the thickness of the steel sheet. However, this value may vary depending on the specific requirements and limitations of the project. It is important to consult with engineering and fabrication professionals who have expertise in working with steel sheets to determine the appropriate bending radius for a given application.

- Q: What is the standard size of steel sheets?

- The standard size of steel sheets can vary depending on the specific application and industry. However, a common standard size for steel sheets is typically around 4 feet by 8 feet.

- Q: Are steel sheets suitable for medical equipment manufacturing?

- Yes, steel sheets are suitable for medical equipment manufacturing. Steel is a versatile and durable material that is commonly used in the production of medical equipment. It offers several advantages such as high strength, corrosion resistance, and ease of customization. Steel sheets can be easily formed, welded, and machined to create complex shapes and structures required for medical equipment. Additionally, steel is a hygienic material that can be easily cleaned and sterilized, making it suitable for use in healthcare settings. Overall, steel sheets are a reliable choice for manufacturing medical equipment due to their strength, durability, and ease of fabrication.

- Q: Are steel sheets suitable for architectural projects?

- Architectural projects can indeed utilize steel sheets as they offer numerous advantages. Steel, being a versatile and durable material, is highly suitable for such applications. First and foremost, steel sheets possess immense strength, enabling them to bear heavy loads. This makes them perfect for structural elements in buildings. The high strength-to-weight ratio of steel sheets allows for the creation of large and open spaces without the need for excessive supporting columns or walls. Consequently, steel sheets are ideal for constructing expansive interior spaces like atriums, stadiums, and other architectural projects. Furthermore, steel sheets can be easily shaped and formed into various architectural designs. They can be curved, rolled, or bent to fashion unique and intricate structures. Steel's malleability empowers architects and designers to challenge conventional building designs and create visually stunning and innovative structures. Moreover, steel sheets exhibit resistance to corrosion, weathering, and fire, making them suitable for outdoor applications and ensuring the longevity of architectural projects. The durability of steel also translates into minimal maintenance requirements throughout its lifespan, resulting in long-term cost savings. In addition, steel sheets offer a wide range of finishes, textures, and colors, facilitating customization and aesthetic versatility in architectural projects. Whether aiming for a sleek and modern design or a rustic and industrial look, steel sheets can be tailored to meet the desired aesthetic requirements of the project. To sum up, steel sheets are an excellent choice for architectural projects owing to their strength, versatility, durability, and aesthetic appeal. Their ability to withstand heavy loads, be shaped into various designs, resist corrosion and fire, and offer customization options make them a favored material for architects and designers to turn their visions into reality.

- Q: Can steel sheets be used for electrical conductivity?

- No, steel sheets are not typically used for electrical conductivity as steel is a poor conductor of electricity compared to other metals like copper or aluminum.

- Q: Can steel sheets be used for interior wall cladding?

- Yes, steel sheets can be used for interior wall cladding. They can provide a modern and industrial aesthetic, are durable, and can be easily cleaned. However, it is important to consider proper insulation and fireproofing measures when using steel sheets for interior applications.

Send your message to us

HOT-DIP Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords