Hot-Dip Galvanized Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

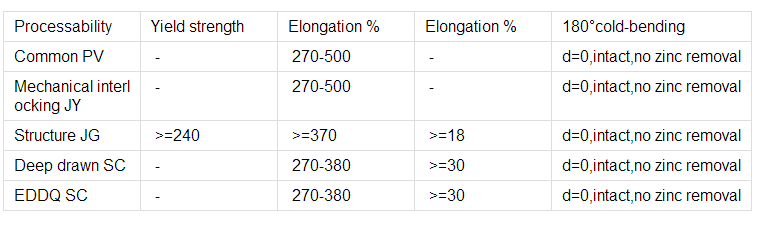

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the difference between brushed and polished stainless steel sheets?

- The main difference between brushed and polished stainless steel sheets lies in their surface finish. Brushed stainless steel sheets have a textured, linear pattern created by brushing the surface with abrasive materials, giving it a matte appearance. On the other hand, polished stainless steel sheets have a smooth, reflective surface achieved by polishing the steel with a fine abrasive compound.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Yes, stainless steel sheets can be used for railway infrastructure. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various applications in the railway industry. It can be used for railway tracks, bridges, platforms, and other structures that require high strength and long-lasting performance. Additionally, stainless steel's low maintenance requirements and ability to withstand harsh environmental conditions make it an ideal choice for railway infrastructure.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Yes, stainless steel sheets can be used in the aerospace industry. Stainless steel possesses excellent strength, corrosion resistance, and high-temperature stability, making it suitable for various aerospace applications such as aircraft frames, engine components, and structural parts.

- Q: Can stainless steel sheets be used for bridge construction?

- Yes, stainless steel sheets can be used for bridge construction. Stainless steel is a highly durable and corrosion-resistant material, making it an excellent choice for bridge construction where exposure to harsh environmental conditions is a concern. Stainless steel sheets offer structural strength, stability, and long-term reliability, making them suitable for various bridge components such as beams, girders, and decking. Additionally, stainless steel's aesthetic appeal and low maintenance requirements further contribute to its suitability for bridge construction projects.

- Q: What are the different types of surface finishes for stainless steel sheets?

- There are several different types of surface finishes available for stainless steel sheets, each offering unique characteristics and appearances. Some of the most common surface finishes are: 1. No.1 Finish: This is the most basic stainless steel finish, also known as hot rolled or annealed finish. It has a dull, rough appearance with visible grain lines and is mainly used for industrial applications where aesthetics are not a concern. 2. No.2B Finish: This is a bright, smooth finish achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It has a semi-reflective appearance and is commonly used for kitchen appliances, decorative trim, and architectural applications. 3. No.4 Finish: This finish is achieved by brushing the stainless steel sheet with abrasive materials, resulting in a uniform, satin-like appearance. It is often used in commercial kitchens, elevator panels, and decorative applications where a visually appealing and easy-to-clean surface is desired. 4. No.8 Mirror Finish: This is the most reflective surface finish available for stainless steel sheets. It is achieved by polishing the surface to a mirror-like shine using progressively finer abrasives. This finish is commonly used in decorative applications, such as architectural features, automotive trim, and jewelry. 5. Hairline Finish: This finish is achieved by sanding the stainless steel sheet with fine abrasives in a consistent linear pattern. It creates a textured, brushed appearance and is often used for decorative purposes, such as wall cladding, furniture, and signage. 6. Bead Blasted Finish: This finish is achieved by bombarding the stainless steel sheet with small glass beads at high pressure, resulting in a uniform, matte texture. It is commonly used for architectural applications, such as column covers, elevator doors, and facade panels. These are just a few examples of the various surface finishes available for stainless steel sheets, each offering different visual effects, textures, and levels of reflectivity. The choice of finish depends on the desired aesthetic, functionality, and application requirements.

- Q: Are stainless steel sheets recyclable?

- Yes, stainless steel sheets are highly recyclable. Stainless steel is a sustainable and environmentally friendly material that can be recycled indefinitely without losing its properties. The recycling process involves collecting and sorting stainless steel scraps, melting them down, and then reusing the material to create new stainless steel products, including sheets. Recycling stainless steel sheets not only helps conserve natural resources and reduce waste but also saves energy and reduces greenhouse gas emissions associated with the production of new stainless steel.

- Q: Are stainless steel sheets resistant to radiation?

- Yes, stainless steel sheets have excellent resistance to radiation. The high levels of chromium present in stainless steel make it highly resistant to corrosion and oxidation caused by radiation exposure. This property makes stainless steel sheets a suitable choice for various applications in nuclear power plants, medical facilities, and other industries that involve exposure to radiation.

- Q: What is the area of stainless steel plate?

- For example, a steel coil with known weight, thickness, length, width, and price, you can work out the cost price of each meter, and then you can set the price as you expect it

- Q: Can stainless steel sheets be used in the automotive industry?

- Yes, stainless steel sheets can be used in the automotive industry. Stainless steel is often used in the construction of automotive parts due to its exceptional strength, durability, and resistance to corrosion. It is commonly used in the production of components such as exhaust systems, fuel tanks, bumpers, and trim. Stainless steel sheets offer a high degree of flexibility in terms of design possibilities, allowing manufacturers to create complex shapes and structures. Additionally, stainless steel's aesthetic appeal and ease of maintenance make it a popular choice in the automotive industry.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can be used for decorative lighting fixtures. Stainless steel is a versatile material that is known for its durability, corrosion resistance, and sleek appearance, making it suitable for creating stylish and long-lasting lighting fixtures. Additionally, stainless steel can be easily manipulated into various shapes and designs, allowing for creative and unique decorative lighting options.

Send your message to us

Hot-Dip Galvanized Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords