High Tensile Strength PP Biaxial Geogrids and Geocells

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---PP Biaxial Geogrid

Introduction:

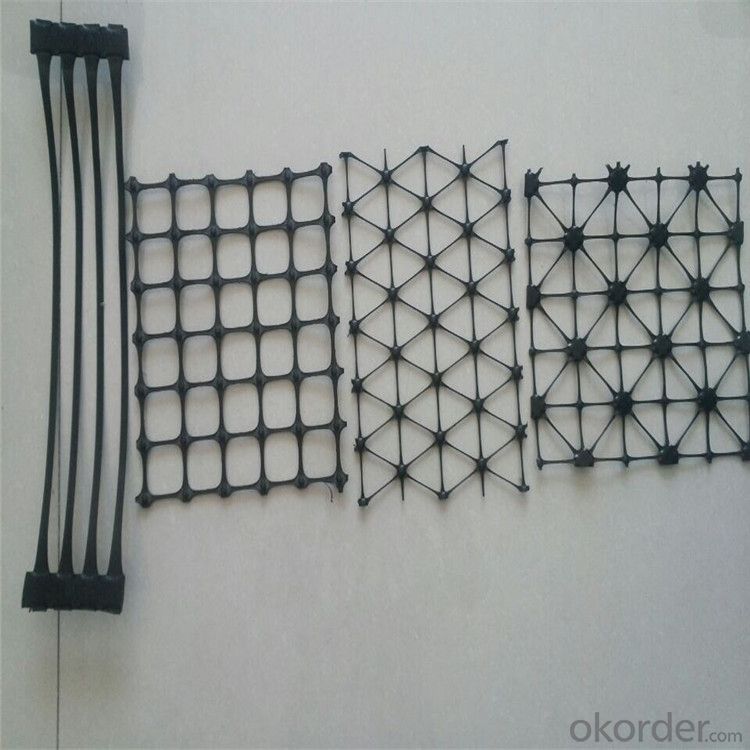

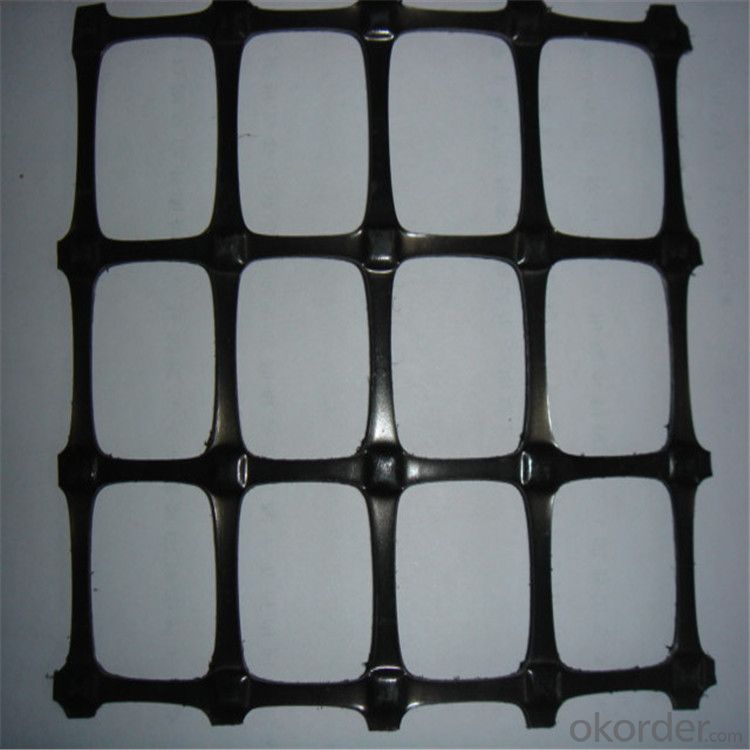

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features:

1. With high tensile strength in longitudinal and transverse directions

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ;

reducing project cost and maintenance cost.

Properties of PP Biaxial Geogrid (Test Method: ASTM D 6637)

Item Spec | TGSG 15-15 | TGSG 20-20 | TGSG 25-25 | TGSG 30-30 | TGSG 35-35 | TGSG 40-40 | TGSG 45-45 | TGSG 50-50 | ||

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

Note: MD: Machine direction

TD: Transverse direction

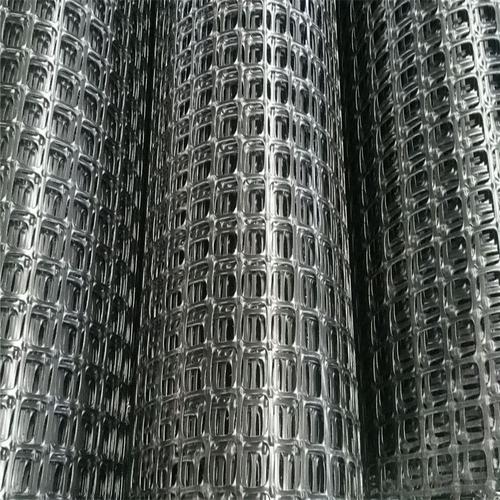

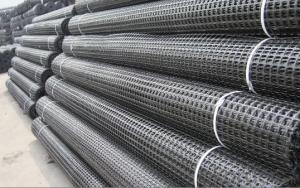

Images of PP Biaxial Geogrid

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as the type and strength of the geogrid material, the required overlap or seam allowance, the recommended depth of installation, the recommended slope angle for placement, and any specific site preparation or soil compaction requirements. Other factors to consider may include the desired load-bearing capacity, the expected lifespan of the geogrid, and any additional reinforcement or anchoring methods necessary. It is important to consult the manufacturer's guidelines and any relevant engineering or construction standards for specific specifications and recommendations.

- Q: The cheapest two-way plastic geogrid manufacturers, two-way plastic geogrid prices?

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%

- Q: Can geogrids be used in gabion wall construction?

- Yes, geogrids can be used in gabion wall construction. Geogrids are often used to reinforce the structure of gabion walls, providing additional strength and stability. They are typically placed within the gabion baskets to improve the overall performance and durability of the wall.

- Q: What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures are generally minimal. Geogrids are designed to provide long-lasting reinforcement and stability to structures, reducing the need for frequent maintenance. However, periodic inspections should be conducted to ensure the integrity of the geogrid and identify any potential damages or signs of degradation. In some cases, routine cleaning and removal of debris may be necessary to prevent clogging or obstruction of the geogrid. Additionally, if any issues or damages are detected, prompt repair or replacement of the geogrid may be required to maintain the structural integrity and performance of the reinforced structure.

- Q: Are geogrids resistant to aging?

- Yes, geogrids are generally resistant to aging. They are designed to withstand long-term exposure to environmental factors such as UV radiation, chemicals, and temperature variations, ensuring their durability and longevity.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of the geogrid material used can significantly impact the overall cost. Higher-quality geogrids may initially be more expensive but offer better long-term performance, potentially reducing maintenance and repair costs over time. Additionally, the design and engineering of the structure play a crucial role. Properly designed geogrid-reinforced structures can optimize material usage and minimize construction costs. The expertise and experience of the engineers and contractors involved also contribute to the cost-effectiveness, as their knowledge can help avoid unnecessary expenses and ensure efficient construction. The specific site conditions, such as soil characteristics and slope stability, are also important factors. Geogrids are typically used to enhance soil stability, so the suitability of the soil for reinforcement and the extent of reinforcement required can impact costs. Difficult terrain, challenging access, or the need for additional site preparation can also increase costs. Lastly, the lifespan and durability of geogrid-reinforced structures should be considered. While geogrids are designed to be long-lasting, factors like environmental conditions, loading requirements, and proper installation can affect their performance. Investing in high-quality materials and proper installation methods may initially increase costs but can result in longer service life and reduced maintenance expenses in the long run.

- Q: Are geogrids suitable for use in steep slopes?

- Yes, geogrids are suitable for use in steep slopes. They provide reinforcement and stability to the soil, reducing the risk of erosion and landslides. Geogrids are designed to distribute loads and improve the overall strength of the slope, making them an effective solution for steep terrain.

- Q: Can geogrids be installed on steep slopes?

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in slope stabilization applications to reinforce the soil and prevent erosion. They provide stability and support to the slopes, even in challenging terrains with steep inclines.

- Q: Is it the same thing as two way tgsg30-30 geogrid and two - way plastic geogrid

- "Bidirectional geogrid tgsg30-30" is a specification for biaxially oriented plastic geogrid in; "30-30" means: per meter of longitudinal and transverse tensile force is greater than the degree of 30KN/m.

- Q: The dam is protection of geomembrane or gabion.

- The protective effect is good, and the soil erosion is prevented

Send your message to us

High Tensile Strength PP Biaxial Geogrids and Geocells

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords