Fiberglass Slope Reinforcement Geogrids for Road Pavement Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

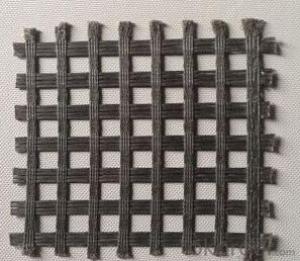

Fiberglass Geogrid Products Profile

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

Fiberglass Geogrid Products Features

It is characterized by high tensile strength in axial and lateral directions low stretch rate, alkaili-resistance, low temperature-assistance as well as convenience in construcion and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Fiberglass Geogrid Products Advantages

High strength

High modulus

Low temperature resistance

Very convenience in construction

Very competitve price

Fiberglass Geogrid Specifications

Item : | Best selling fiberglass geogrid with non woven |

Material : | Non woven |

Feature : | Biodegradable and Printing logo never rub off |

Industrial Use: | Shopping/Apparel/Packaging/Grocery, etc |

Custom Order : | Accept |

Color : | Customized can reach 10 colors |

Shipping & Payment: | |

Price : | very competitive in China |

MOQ: | 5,000 pcs |

Samples: | Free sample offered |

Samples lead time : 8-15 days,depends on your order | |

Refund part/full of the sample fee after order confirmed | |

Delivery Time : | 10-15 days |

Port : | Guangzhou/Shenzhen/Hongkong |

Payment Terms: | T/T,L/C, |

50% deposit,and 50% balance before shipment. | |

Certificates: | ISO9001/ISO2008/SGS/ROHS |

FAQ

1. What's the usage of Polypropylene Biaxial geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of Polypropylene Biaxial geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

Fiberglass Geogrid Photos

- Q: How do geogrids improve the performance of unpaved trails?

- Geogrids improve the performance of unpaved trails by providing reinforcement to the soil, increasing its stability and load-bearing capacity. They prevent soil erosion and rutting by distributing the applied loads more evenly, reducing the likelihood of surface deformation. Additionally, geogrids enhance the drainage capabilities of the trail, allowing for better water infiltration and reducing the chances of water accumulation and subsequent damage.

- Q: What are the procedures for using two-way geogrid

- 1 bidirectional geogrid is used to increase the bearing capacity of the road (ground) foundation, and the service life of the Yan Changlu (ground) foundation.2 bidirectional geogrid used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.3 bidirectional geogrid for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments on collapsible soils?

- Yes, geogrids can be effectively used in the reinforcement of mechanically stabilized earth (MSE) bridge abutments on collapsible soils. Geogrids are commonly used in MSE structures to provide additional strength and stability by improving soil retention and preventing lateral movement. In the case of collapsible soils, geogrids can help distribute the applied loads more evenly, reducing the risk of soil settlement and potential bridge abutment failure. Therefore, incorporating geogrids in the reinforcement of MSE bridge abutments on collapsible soils can be a reliable and efficient solution.

- Q: Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are often installed to provide additional support and stability to the surrounding soil or rock mass, reducing the risk of collapse or deformation. They can help distribute the applied loads and increase the overall strength of the structure, making them a suitable choice for reinforcing tunnels and underground excavations.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in civil engineering applications to reinforce soil and provide stability to structures. In the case of pipelines, geogrids can be used to prevent soil erosion, improve load distribution, and increase the overall stability of the ground, thereby enhancing the long-term performance and safety of the pipeline.

- Q: How many Chinese geogrid manufacturers? How many famous

- In foreign markets, the high level of the grid, it is basically the competition with TANSER

- Q: What are the typical properties and characteristics of geogrids?

- Geogrids are typically made of high-strength polymers such as polyester or polypropylene, which give them excellent tensile strength and dimensional stability. They are characterized by their open-grid structure, allowing for soil interlocking and enhanced load distribution. Geogrids also possess high resistance to ultraviolet (UV) degradation and chemical corrosion, making them suitable for long-term applications in various environmental conditions. Additionally, these materials have low elongation under load, enabling them to provide long-term reinforcement and stabilization to soils and aggregates.

- Q: Can geogrids be used in landfill construction?

- Yes, geogrids can be used in landfill construction. Geogrids are commonly used as reinforcement materials in landfill engineering to improve stability, increase load-bearing capacity, and prevent soil erosion. They are effective in enhancing the overall performance and longevity of landfills.

- Q: How do geogrids enhance the stability of steep railway embankments?

- Geogrids enhance the stability of steep railway embankments by providing reinforcement and confinement to the soil. They are installed within the embankment to distribute the load more effectively, reducing lateral movement and preventing soil erosion. This additional support increases the embankment's resistance to slope failure, improving its overall stability and ensuring the safe operation of the railway.

- Q: How long do geogrids typically last?

- Geogrids typically last for a long time, with a lifespan ranging from 20 to 100 years, depending on factors such as the type of geogrid, installation conditions, and the application it is being used for.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Slope Reinforcement Geogrids for Road Pavement Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords