PP Biaxial Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

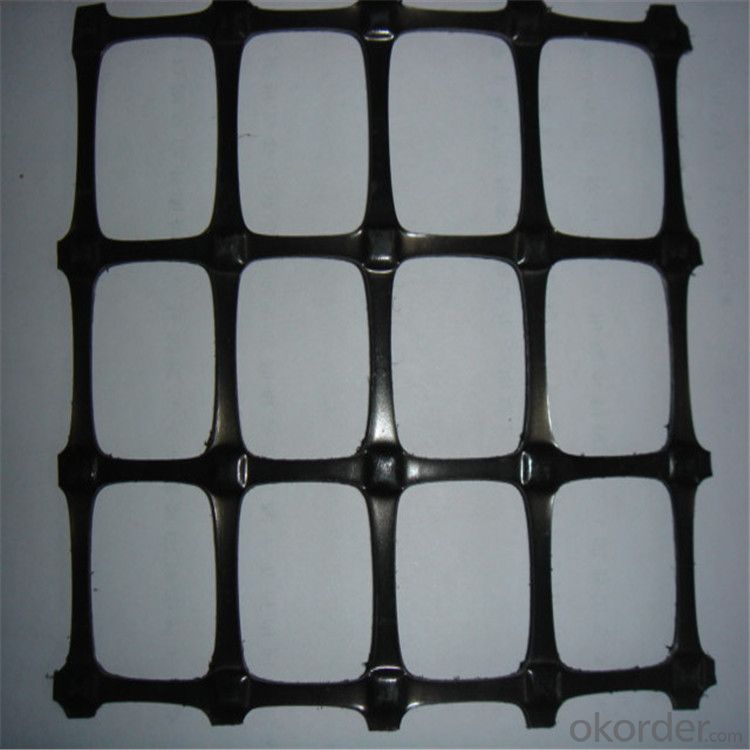

Product Specification---PP Biaxial Geogrid

Introduction:

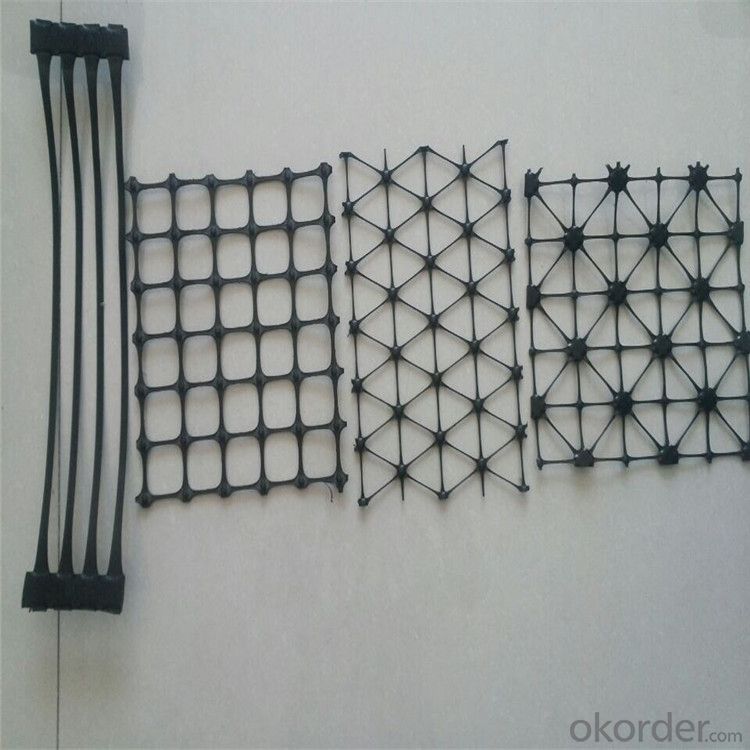

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features:

1. With high tensile strength in longitudinal and transverse directions

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application:

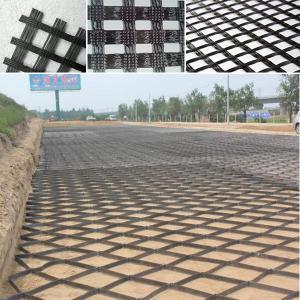

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ;

reducing project cost and maintenance cost.

Properties of PP Biaxial Geogrid (Test Method: ASTM D 6637)

Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | |

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Item Spec | TGSG 15-15 | TGSG 20-20 | TGSG 25-25 | TGSG 30-30 | TGSG 35-35 | TGSG 40-40 | TGSG 45-45 | TGSG 50-50 | ||

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

Note: MD: Machine direction

TD: Transverse direction

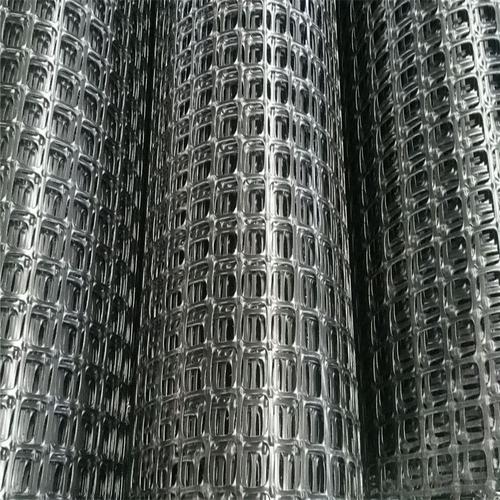

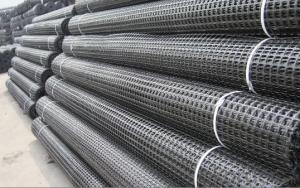

Images of PP Biaxial Geogrid

- Q: Can geogrids be used in mining applications?

- Yes, geogrids can be used in mining applications. Geogrids are widely used in mining operations for various purposes such as soil stabilization, slope reinforcement, and erosion control. They provide structural support and enhance the stability of mining structures, including excavations, embankments, and retaining walls. Additionally, geogrids can help prevent soil erosion and improve the overall safety and efficiency of mining operations.

- Q: Are geogrids effective in reducing differential settlement in foundations?

- Yes, geogrids are effective in reducing differential settlement in foundations. They provide additional reinforcement and improve the load-bearing capacity of the soil, thereby distributing the loads more evenly and reducing the differential settlement between different areas of a foundation.

- Q: Are geogrids suitable for use in railway trackbed stabilization?

- Yes, geogrids are suitable for use in railway trackbed stabilization. Geogrids provide reinforcement and stabilization to the trackbed by distributing loads, reducing settlement, and improving overall performance and longevity of the railway tracks.

- Q: Geogrid and geotextile, the role is the same?

- Geogrid and geotextile are different

- Q: Are geogrids resistant to corrosion?

- Yes, geogrids are generally resistant to corrosion. They are commonly made from materials such as high-density polyethylene (HDPE) or polyester, which are not prone to corrosion. This makes geogrids suitable for various applications in civil engineering and construction, where they may be exposed to moisture, chemicals, or other corrosive elements.

- Q: What is the lifespan of a geogrid?

- The lifespan of a geogrid can vary depending on several factors such as the type and quality of the material used, the environmental conditions it is exposed to, and the level of maintenance and care it receives. However, on average, a geogrid can have a lifespan ranging from 20 to 50 years.

- Q: Can geogrids be used in ground reinforcement for military installations?

- Yes, geogrids can be used in ground reinforcement for military installations. Geogrids are commonly used to improve soil stability, increase load-bearing capacity, and enhance erosion control. They can effectively reinforce the ground and provide a stable foundation for military infrastructure such as roads, runways, and temporary structures.

- Q: Can geogrids be used in shoreline protection against wave action?

- Yes, geogrids can be used in shoreline protection against wave action. Geogrids are commonly used to stabilize soil and prevent erosion. When installed along the shoreline, geogrids can help absorb the energy of the waves, reduce erosion, and provide protection to the shoreline. They are often combined with other materials, such as rocks or vegetation, to create an effective barrier against wave action.

- Q: What is the typical lifespan of geogrids?

- The typical lifespan of geogrids can vary depending on factors such as the quality of the material, the environmental conditions they are exposed to, and the level of stress they experience. However, geogrids are generally designed to have a lifespan of 20 to 50 years.

- Q: What are the factors to consider when selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, several factors need to be considered. These include the desired strength and stiffness of the geogrid, the anticipated load and traffic conditions, the soil type and properties, the environmental and climate conditions, the installation and construction methods, and the project budget. Additionally, the compatibility of the geogrid with other materials and its long-term durability should also be taken into account. Ultimately, the geogrid chosen should be able to effectively reinforce and stabilize the soil, withstand the expected loads, and provide optimal performance for the specific application.

Send your message to us

PP Biaxial Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords