CE Certified Vegetated Polyester Geogrids Hot

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

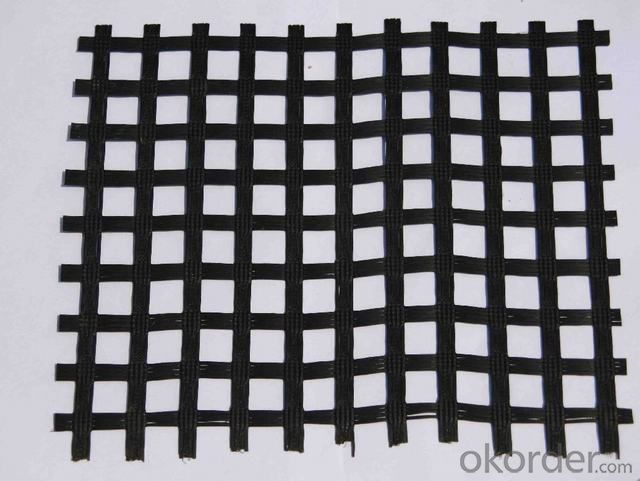

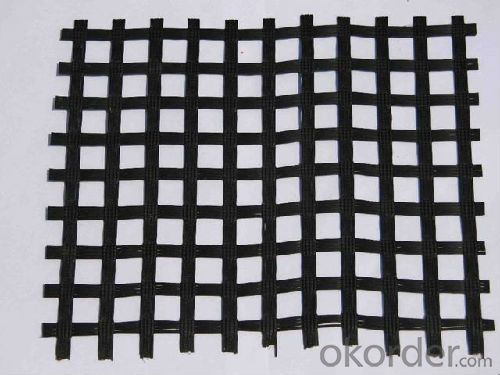

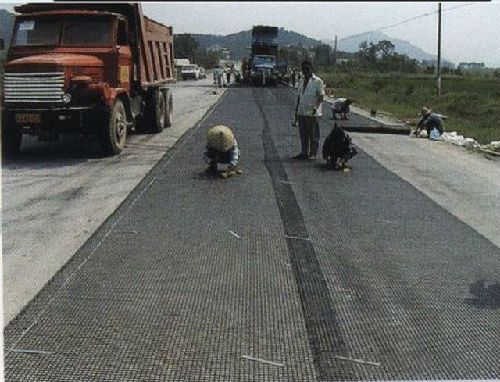

Biaxial geogrids are used in base reinforcement applications such as roads and parking lots. Biaxial geogrids provide good tensile strength in both principle directions. Biaxial geogrids primary functions: reinforcement. Secondary functions: none. Lianyi has many different styles of biaxial geogrids available

Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

Strength | ||||||||

(KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

Polyester | <13% | 13% | 13% | 13% | 13% | 13% | 13% | |

Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

(Fiberglass) | ||||||||

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

- Q: Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are commonly used in landfill capping systems to provide reinforcement and stability to the cover materials. They help distribute loads and reduce stress on the cover system, improving its integrity and performance.

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Polyester warp knitted polyester coating is PVC glue, glass fiber geogrid is that sensitive asphalt rubber. An anti-corrosion, a alkali resistance. Material is not the same, the appearance is not difficult to distinguish between experts

- Q: Can geogrids be used in reinforcement of foundation slabs?

- Yes, geogrids can be used in the reinforcement of foundation slabs. Geogrids are widely used in civil engineering projects to improve the stability and load-bearing capacity of soil. When placed in the foundation slab, geogrids help distribute the load more evenly, reducing the risk of cracking and settling. Additionally, geogrids provide enhanced resistance to lateral forces and can help mitigate the effects of soil expansion and contraction. Overall, geogrids can greatly improve the performance and longevity of foundation slabs.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q: How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by reinforcing and stabilizing soil, thereby minimizing the need for excessive excavation and the use of additional materials such as stone or concrete. This reduces the demand for natural resources like aggregates, sand, and gravel, leading to a more sustainable and eco-friendly construction process.

- Q: Are geogrids suitable for reinforcement of embankments on soft soils?

- Yes, geogrids are suitable for reinforcement of embankments on soft soils. Geogrids provide a strong and stable reinforcement layer that helps distribute loads and improve the overall stability of the embankment. They also help to prevent soil erosion and increase the bearing capacity of the soft soils, making them an effective solution for reinforcing embankments on such terrain.

- Q: Are geogrids suitable for stabilizing soft soils?

- Yes, geogrids are suitable for stabilizing soft soils. They are commonly used in geotechnical engineering to enhance the stability and strength of weak or unstable soils. Geogrids provide reinforcement by distributing loads and restricting lateral movement, thereby improving the overall stability of the soil.

- Q: What is the difference between polyethylene geogrid and uni directional high strength geogrid

- Purpose of service life. OneThe bidirectional grid is suitable for increasing the bearing capacity of the road (ground) base, and the service life of the Yan Changlu base. TwoThe utility model relates to a bidirectional grid which is suitable for preventing the collapse of the road surface and the generation of cracks.

- Q: Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be used in soil reinforcement for load-bearing platforms. Geogrids are commonly used in civil engineering projects to enhance the stability and strength of soil. By providing tensile reinforcement, geogrids distribute the load across a wider area, reducing settlement and preventing soil erosion. This makes them an effective solution for reinforcing soil in load-bearing platforms, increasing their load-bearing capacity and overall stability.

- Q: What kind of geogrid can meet the requirements

- Polypropylene single pull plastic grille TGDG80 meet the requirements

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

CE Certified Vegetated Polyester Geogrids Hot

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords