Triax Geogrids - Polypropylene Biaxial Geogrid with CE Certificate for High Tear-Resistance Soil Reinforcement

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

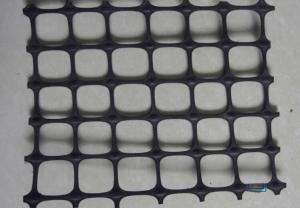

Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

1. Introudction for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

Plastic earthwork grid is a drawing of a square or rectangle of polymer mesh material, according to its manufacture different stretching direction can be unidirectional and bi-stretch. It is in the extruded polymer sheets (raw materials for PP or HDPE) punch, and heating purposes of directional stretch. Unidirectional grid only stretch along plate length direction, which is biaxially oriented grid continues to be one of the grid and then in the direction of its length vertical stretch.

2. Features for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

a). Low Elongation

b).High Tensile Strength

c). Warp / Weft: tensile strength(kn/m): 15,20, 30, 40, 50

d). High Tear-resistance

3. Specifications and Technical Data for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

4. Some photos for Polypropylene Biaxial GeoGrid with CE Certificate with High Tear-resistance for Soil Reinforcement

- Q: Geotextile manufacturers which good? Where is the best geotextile, geotextile manufacturers

- Needle punched nonwoven fabric and PE film composite geotextile:A specification film cloth, a cloth film two, maximum width of 4.2 meters is the main raw material to use acupuncture non-woven polyester staple fiber, PE film by composite, is mainly used for seepage control, applicable to rail, highway, tunnel, subway, airport project. Geotextile manufacturers can choose Wo environmental protection

- Q: Are geogrids environmentally friendly?

- Geogrids can be considered environmentally friendly as they are typically made from recycled materials and can be reused or recycled after their lifespan. Additionally, geogrids help stabilize soil, reduce erosion, and enhance drainage, leading to improved environmental conditions.

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: How do geogrids improve the performance of geotechnical structures?

- Geogrids improve the performance of geotechnical structures by enhancing their load-bearing capacity, reducing soil erosion, and providing stability. These synthetic materials are used to reinforce soil, increasing its strength and preventing it from shifting or settling. By distributing the load more evenly, geogrids minimize the potential for structural failure and improve overall stability. Additionally, they help to control soil erosion by stabilizing slopes and retaining walls, reducing the risk of landslides and erosion-related damage.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in high rainfall areas?

- Geogrids improve the performance of mechanically stabilized slopes in high rainfall areas by providing reinforcement and stability to the soil. They increase the shear strength and prevent soil erosion, reducing the risk of slope failure or landslides. Additionally, geogrids allow for better drainage and water flow through the soil, reducing the buildup of water pressure and improving overall slope stability in high rainfall conditions.

- Q: What is the meaning of the geogrid reinforced asphalt in the project list

- You are not me, I was the construction of geogrid manufacturers, generally used in the mygeogrid on the road of geogrid is fiberglass geogrid, in your compacted Subgrade after injection will then laying a layer or several layers of fiberglass geogrid, after paving asphalt, the operation process is this, geogrid and asphalt is two kinds of different products

- Q: Soil and water conservation measures in the interim geogrid do

- The grille and grass, slope is lower than 1:0.75, multistage slope, slope height is less than 8m per level.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners?

- Yes, geogrids do provide reinforcement to geosynthetic asphalt liners.

- Q: Are geogrids suitable for use in mechanically stabilized embankments?

- Yes, geogrids are suitable for use in mechanically stabilized embankments. Geogrids provide reinforcement and stability to the embankment by distributing lateral forces and reducing soil movement. They improve the overall strength and performance of the embankment, making them an effective solution for stabilizing soil and preventing erosion.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials made from polymers, typically high-density polyethylene (HDPE) or polyester, that possess a unique set of properties and characteristics. These include high tensile strength, low elongation, and excellent resistance to chemical degradation and biological attack. Geogrids also have a high modulus of elasticity, which allows them to distribute stress and improve the load-bearing capacity of soils and aggregates. They are typically lightweight and easy to handle, making them convenient for construction applications. Geogrids exhibit excellent dimensional stability and resistance to creep, ensuring their long-term effectiveness. They are also resistant to UV degradation and have a long design life. Overall, geogrids are versatile materials that provide reinforcement, stabilization, and confinement in various civil engineering projects, such as road construction, slope stabilization, and erosion control.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Triax Geogrids - Polypropylene Biaxial Geogrid with CE Certificate for High Tear-Resistance Soil Reinforcement

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 122000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords