Tensar High Strength Manufactured PP Uniaxial Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PP/HDPE Uniaxial Geogrid:

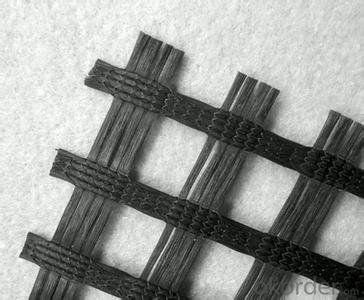

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Uniaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Uniaxial Geogrid:

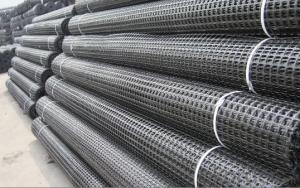

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

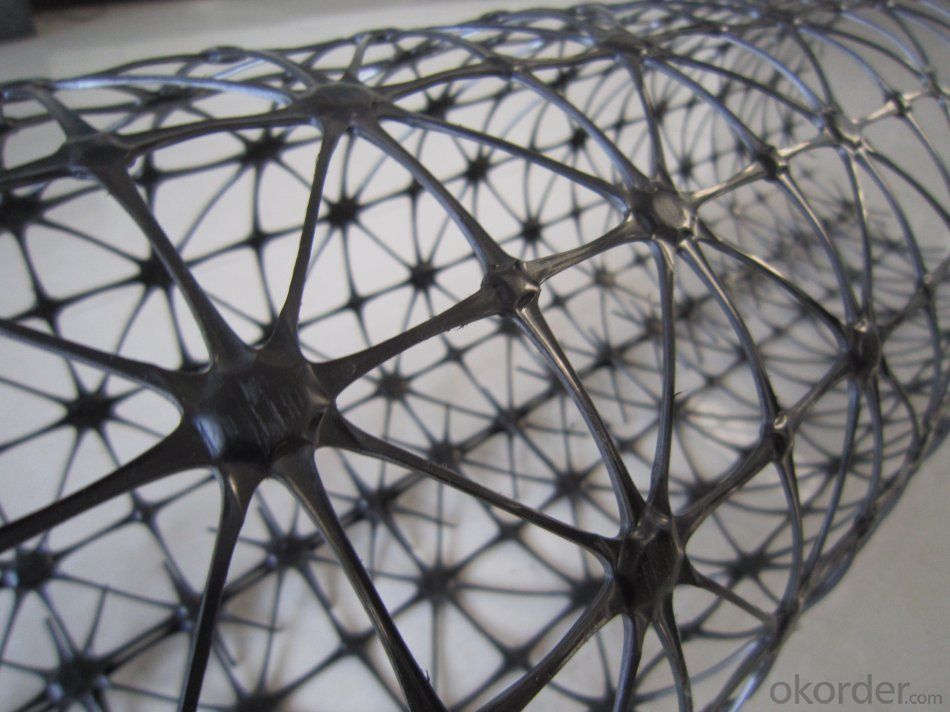

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: The ground treatment is full of geogrid is not along the line direction

- Generally paved along the direction of the road

- Q: What are the factors that affect the installation quality of geogrids?

- There are several factors that can affect the installation quality of geogrids. Some of the key factors include the proper selection and preparation of the subgrade, accurate placement and alignment of the geogrid, appropriate tensioning and anchoring of the geogrid, and the overall construction practices followed during installation. Additionally, factors such as weather conditions, soil type, and site-specific requirements can also impact the installation quality of geogrids.

- Q: What are the applications of geogrids in civil engineering?

- Geogrids are extensively used in civil engineering for various applications such as soil stabilization, slope reinforcement, retaining wall construction, and pavement reinforcement. They provide strength and stability to soil structures, prevent erosion, increase load-bearing capacity, and enhance overall structural integrity. Geogrids are also employed in infrastructure projects like road construction, railway tracks, landfill sites, and coastal protection, contributing to the longevity and durability of these civil engineering projects.

- Q: Are geogrids resistant to hydrolysis?

- Yes, geogrids are generally resistant to hydrolysis.

- Q: How do geogrids improve the performance of mechanically stabilized earth walls?

- Geogrids improve the performance of mechanically stabilized earth walls by providing reinforcement to the soil, increasing its tensile strength and overall stability. The geogrids act as a tension element, distributing the applied loads more uniformly, reducing settlement and potential wall failure. Additionally, they enhance the interaction between the soil and retaining structure, preventing lateral movement and improving overall wall performance.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas?

- Geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas by providing additional strength and stability. These synthetic materials are used to reinforce the soil and prevent it from shifting or sliding during liquefaction events. The geogrids act as a reinforcement layer within the soil, increasing its shear strength and reducing the potential for slope failure. Additionally, geogrids help to distribute loads more evenly across the slope, reducing stress concentrations and improving overall slope stability in liquefaction-prone areas.

- Q: Glass fiber grating with large pulling force for Expressway

- To improve the overall use of polyester geogrid using high strength nylon fiber filament, warp knitting mesh fabric.

- Q: Can geogrids be used in reinforced slopes?

- Yes, geogrids can be used in reinforced slopes. Geogrids are commonly used in reinforced slopes to enhance the stability and strength of the soil. They are designed to distribute the load and provide additional reinforcement to the slope, improving its resistance against erosion and slope failures.

- Q: What is the lifespan of geogrids?

- The lifespan of geogrids can vary depending on several factors such as the quality of the material, installation techniques, and the environmental conditions they are exposed to. However, on average, geogrids are designed to have a lifespan of around 20 to 50 years.

- Q: What are the specifications of the road geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille...... There are many kinds of specifications for each grid

Send your message to us

Tensar High Strength Manufactured PP Uniaxial Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords