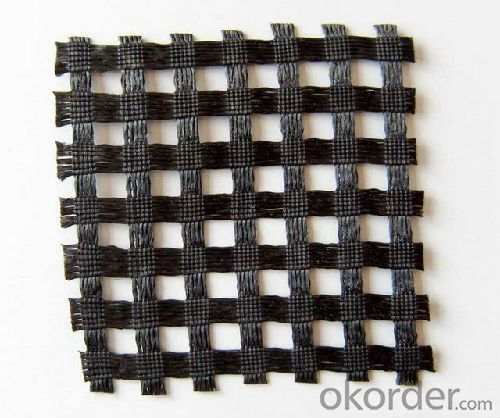

Geogrids for Asphalt - Woven Polyester Geogrid with CE Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction:

The warp knitting polyster geogrid use excel raw materials, with warp knitting oriented structrue , latitude and longitude in the fabric to the yarn between not curving condition, the intersection unifies mutually with the excel in textile fiber filament bundle, forms the reliable combining site, displays its mechanical properties fully.

2. Features

The warp knitting polyste geogrid has high intensity, the high module, the low creep, anti-aging, anti-embrittlement, the tensile strength to be high strength, high anti-peel strength, with the soil crushed stone binding force strong.

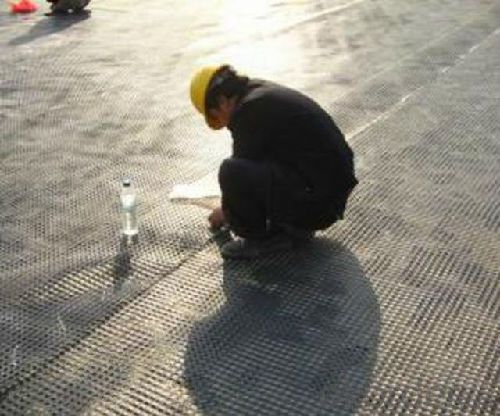

3. Application

Reinforcing embankments of road, car parks, railways and airports

Embankments on piles

Reinforcement of fillings and soils, industrial areas, halls and shopping centers

Retaining walls

Landslides repairing

The construction of noise barriers

The stabilization of sea, river and reservoir banks

The reinforcement of any type of unstable foundation

Specification | Tensile Strength KN/M longitude latitude | Percetage Elongation ≤ % | Covering Rate ≥ % | |

100×120 | 120 | 100 | 10 | 20 |

100×100 | 100 | 100 | 10 | 20 |

80×80 | 80 | 80 | 10 | 20 |

80×50 | 80 | 50 | 10 | 20 |

50×50 | 50 | 50 | 10 | 20 |

50×35 | 50 | 35 | 10 | 20 |

40×40 | 40 | 40 | 10 | 20 |

30×30 | 30 | 30 | 10 | 20 |

20×20 | 20 | 20 | 10 | 20 |

100 | 100 | 10 | 10 | 20 |

80 | 80 | 10 | 10 | 20 |

50 | 50 | 10 | 10 | 20 |

40 | 40 | 10 | 10 | 20 |

- Q: How do geogrids improve the load-bearing capacity of foundations?

- Geogrids improve the load-bearing capacity of foundations by providing reinforcement and stability to the soil. They are placed within the foundation layers and act as a structural support, distributing the load more evenly across the soil. This prevents soil movement and settlement, ultimately enhancing the foundation's ability to bear heavy loads.

- Q: Can geogrids be used in underwater applications?

- Yes, geogrids can be used in underwater applications. They are often employed in marine construction projects, such as offshore breakwaters, submerged revetments, and coastal protection systems. Geogrids are designed to withstand the harsh conditions of underwater environments and provide stability to soil or fill materials, preventing erosion and improving the overall performance of underwater structures.

- Q: Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. Geogrids are commonly used in such applications due to their ability to effectively distribute loads, improve soil stability, and prevent soil erosion. They provide a cost-effective solution for enhancing the strength and durability of the soil, ensuring the safe and reliable installation of pipelines.

- Q: EG90R what is the geogrid material?

- Refers to a one-way reinforced geogrid, also known as a one-way tensile plastic geogrid, EG90R that is pulling 90KN, material polypropylene, polyethylene, polyethylene better, but also more expensive!! Details can call my name oh!

- Q: Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids are engineered materials that provide soil stabilization and reinforcement, making them effective in preventing erosion and maintaining the stability of steep slopes. They enhance the integrity of the soil structure and distribute the load evenly, reducing the risk of slope failure. Geogrids have been extensively used in various applications, including reinforced steep slopes, due to their high tensile strength, durability, and ability to withstand extreme forces.

- Q: Can geogrids be used in floating road construction?

- Yes, geogrids can be used in floating road construction. Geogrids are commonly employed in road construction projects to improve the stability and load-bearing capacity of the road structure. When used in floating road construction, geogrids help to distribute and reinforce the load, reducing the pressure on the underlying soil or subgrade. This ensures better performance and longevity of the road, even in challenging or soft soil conditions.

- Q: Can geogrids be used in underground mining applications?

- Yes, geogrids can be used in underground mining applications. Geogrids are commonly used in mining operations for reinforcement and stabilization of soil or rock structures. They provide support to prevent soil or rock movement, enhance load distribution, and improve overall stability in underground mining operations.

- Q: Are there any environmental concerns associated with geogrids?

- Yes, there are some environmental concerns associated with geogrids. One concern is that geogrids are often made from non-biodegradable materials such as plastics, which can contribute to pollution and waste accumulation. Additionally, the manufacturing process of geogrids may require the use of fossil fuels and other resources, which can have a negative impact on the environment. However, when used correctly and in appropriate applications, geogrids can also help mitigate certain environmental concerns such as soil erosion and habitat destruction.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids are commonly used to stabilize and reinforce soil in various applications, including sports fields. They can help improve the load-bearing capacity, reduce soil movement, and increase the longevity and durability of the playing surface.

- Q: Overview of fiberglass grille

- With the warp and weft two-way high tensile strength and low elongation, and high temperature resistance, low temperature, aging resistance, corrosion resistance and other excellent properties, is widely used in the asphalt pavement, cement concrete pavement and subgrade reinforcement and railway roadbed, dam slope, airport runway, anti sand control project.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Geogrids for Asphalt - Woven Polyester Geogrid with CE Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords